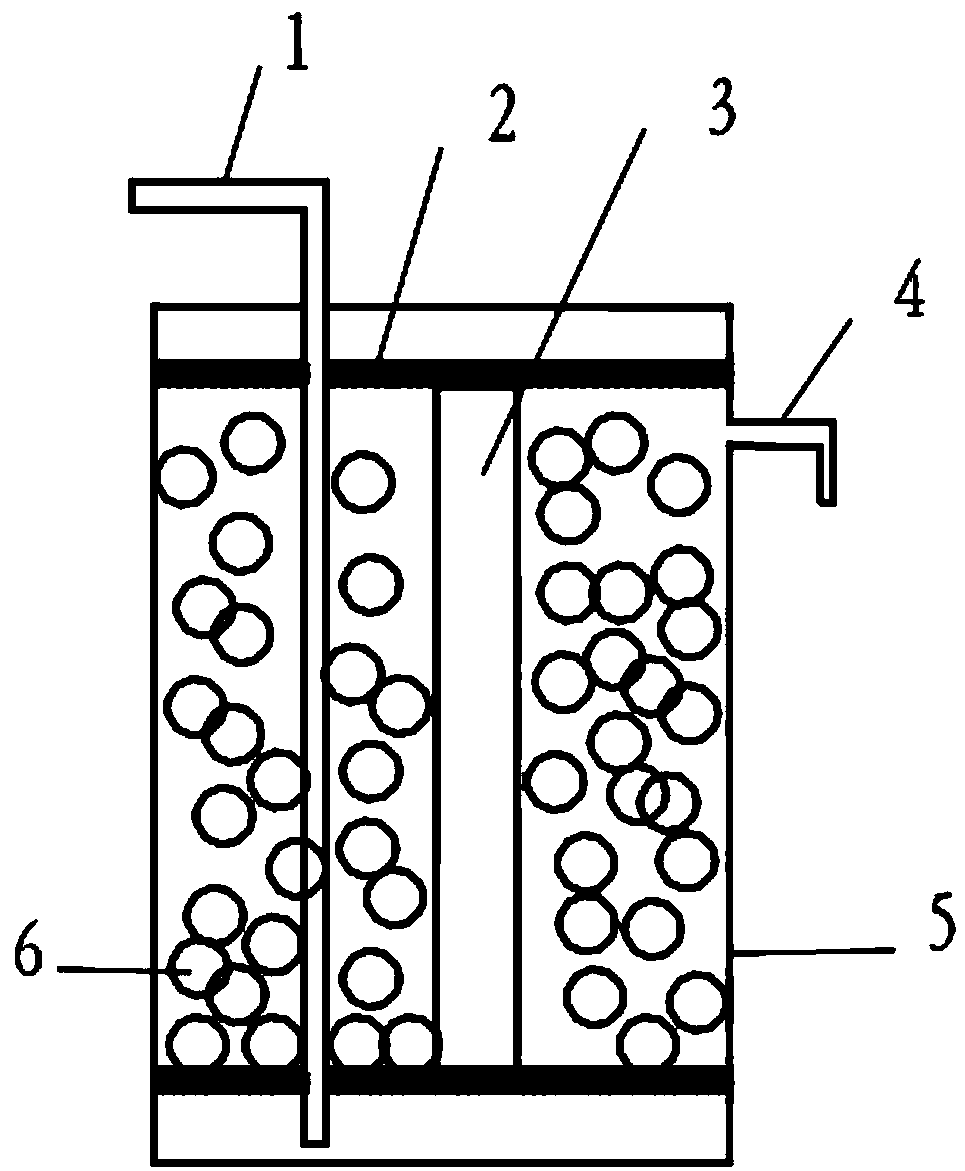

Water purifying column for water dispenser

A water dispenser and water column technology, applied in the field of water purification, can solve problems such as difficult water quality to drink directly, endangering health, and low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The filler includes a modified carrier and active silver ions loaded on the modified carrier; the modified carrier is carried out on the surface of the porous carrier through tetrabutyl titanate and a silane coupling agent. Modified carrier; the amount of tetrabutyl titanate is 3% of the mass of the porous carrier; the amount of the silane coupling agent is 0.5% of the mass of the porous carrier; the amount of the active silver ion is the mass of the porous carrier 2%.

[0021] The filler is prepared in the following manner:

[0022] 1) Modification of the carrier: adding 10 times the mass of water to the porous carrier to obtain a slurry; dissolving tetrabutyl titanate in absolute ethanol 5 times the mass, and adding it dropwise to the stirred slurry, Continue to stir for at least 1 hour after the dropwise addition, and then separate by suction filtration, and dry the obtained filter cake at 120°C to obtain a preliminary modified carrier; disperse the pr...

Embodiment 2

[0024] Embodiment 2: The filler includes a modified carrier and active silver ions loaded on the modified carrier; the modified carrier is carried out on the surface of the porous carrier through tetrabutyl titanate and a silane coupling agent. Modified carrier; the amount of tetrabutyl titanate is 0.1% of the mass of the porous carrier; the amount of the silane coupling agent is 0.1% of the mass of the porous carrier; the amount of the active silver ion is the mass of the porous carrier 0.1%.

Embodiment 3

[0025] Embodiment 3: the filler includes a modified carrier and active silver ions loaded on the modified carrier; the modified carrier is carried out on the surface of the porous carrier through tetrabutyl titanate and a silane coupling agent. Modified carrier; the amount of tetrabutyl titanate is 5% of the mass of the porous carrier; the amount of the silane coupling agent is 1% of the mass of the porous carrier; the amount of the active silver ion is the mass of the porous carrier 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com