Anisotropic neodymium-iron-boron composite magnetic strip and its manufacturing method, externally rotating motor, motor, frequency conversion ceiling fan motor, and hub-type generator

A non-square NdFeB, manufacturing method technology, applied in inductance/transformer/magnet manufacturing, magnetic circuit shape/pattern/structure, circuit, etc., can solve the problem of processing and assembly labor, reducing tire life, tire easy wear, etc. problem, to achieve the perfect waveform curve, improve comfort, and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

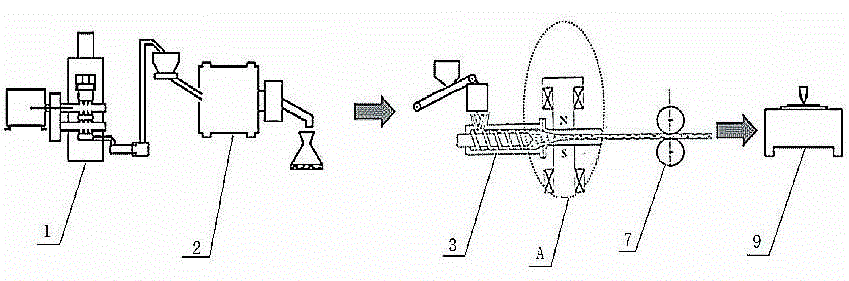

[0035] see figure 1 and figure 2 , the manufacturing method of the anisotropic NdFeB composite magnetic strip comprises the following steps:

[0036] a. Mixing: put NdFeB anisotropic magnetic powder with a mass ratio of 92%, 6% chlorinated polyethylene, 0.9% vulcanizing agent, 0.3% auxiliary vulcanizing agent and 0.8% heat stabilizer into mixing Carry out kneading in machine 1, the time of kneading is 90 minutes, the temperature of kneading is controlled below 70 ℃;

[0037] b. Batch mixing: Pour more than two batches of mixed magnetic powder into the mixing tank 2, and mix in the mixing tank to form the mixed magnetic powder 10;

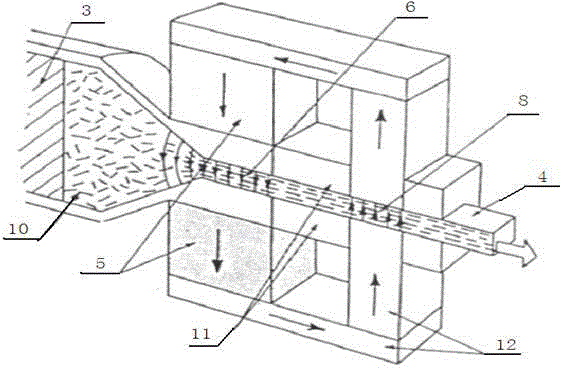

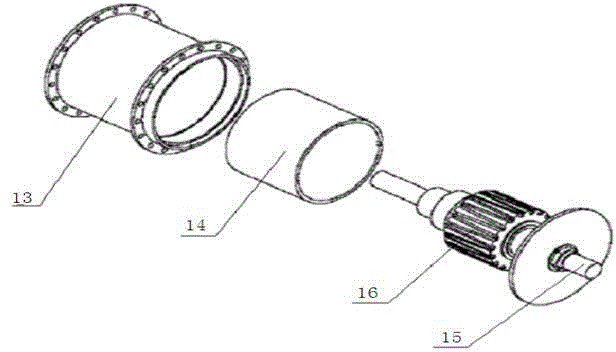

[0038] c. Spiral extrusion sheeting and orientation: send the mixed magnetic powder mixed in batches to the screw conveyor 3 for extrusion to form the magnetic sheet 4, and then the magnetic sheet 4 is oriented by the orientation magnetic field 6 generated by the permanent magnet 5, and then The oriented magnetic sheet 4 is demagnetized; while e...

Embodiment 2

[0044] The manufacturing process of the heterosquare NdFeB composite magnetic strip is exactly the same as that of Example 1, except that trihydroxypropane trimethacrylate produced by Nanjing Jihua Lubricating Oil Co., Ltd. is used instead of triallyl isocyanurate. The characteristics of the anisotropic NdFeB composite magnetic strip prepared by this method are basically the same as those in Example 1, but the odor of the vulcanized rubber produced is smaller than that in Example 1. When the mixed magnetic powder is sent to the screw conveyor for extrusion, the extruded mixture needs to pass through a flat die head with a width of 400mm and a thickness of 5mmn, so the extruded disk becomes 400x5mm in size. The length is determined by the feeding of the screw machine.

Embodiment 3

[0046] The anisotropic NdFeB composite magnetic strip has a width of 400 mm and a thickness of 5 mm. Remanence (Br): 7.95~8.25 KG; iHc: 8.2~9.2 Oe; (BH)max: 11.7~13.2 MGOe. The manufacturing method is the same as that of the anisotropic NdFeB composite magnetic strip in Example 1, and will not be described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com