Measuring method for thickness of extremely thin covering layer

A measurement method and thickness measurement technology, applied in the field of measurement, can solve problems such as inability to carry out measurement work, and achieve the effects of effective measurement and arbitration, effective measurement, and reliable conclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Using the method for measuring the thickness of the ultra-thin coating layer of the present invention, the sample of the thickness of the ultra-thin coating layer on the plane is intercepted and measured.

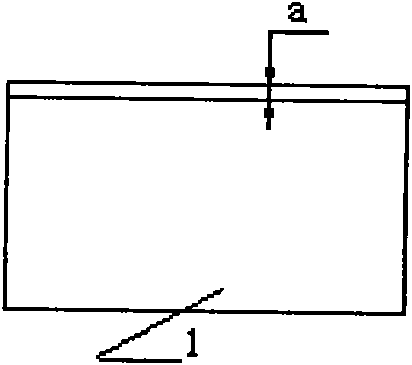

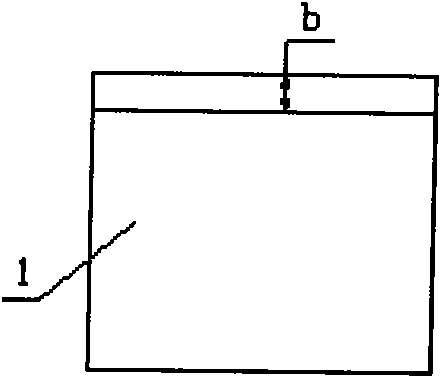

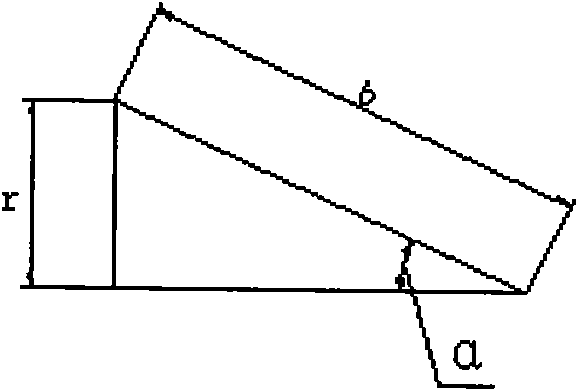

[0045] The intercepted surface of the sample is obliquely intersected with the surface of the covering layer (that is, the surface of the substrate). The angle α of the oblique intersection can be set in advance, or it can be measured after intercepting the sample. The geometric relationship of the coating thickness b on the image 3 As shown, the conversion is carried out according to the final measured value δ=bsinα, and the converted value is taken as the final measured value.

Embodiment 2

[0047] Sample interception and measurement of thickness of extremely thin coating on cylindrical surface

[0048] The intercept surface is oblique to the axis of the cylinder. At this time, the covering layer on the detection surface is an ellipse ring. At the short axis of the ellipse, the section is perpendicular to the surface of the covering layer. The thickness reading is a. The angle between the surface of the layer transitions from 90 degrees to α, and the thickness value measured under the microscope is from a to b, see Figure 4 , the b value should be taken as the reading of the thickness measurement, and converted according to the final measured value = bsinα, and the converted value is taken as the final measured value (the value of α can be measured after cutting the sample).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com