Outer circle measuring structure for impulse turbine model runner

A hydraulic turbine model and impact technology, which is applied in the direction of mechanical diameter measurement, etc., can solve the problem that it is difficult to measure the outer diameter of the runner of the impact turbine model, and achieve the effect of simple structure and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

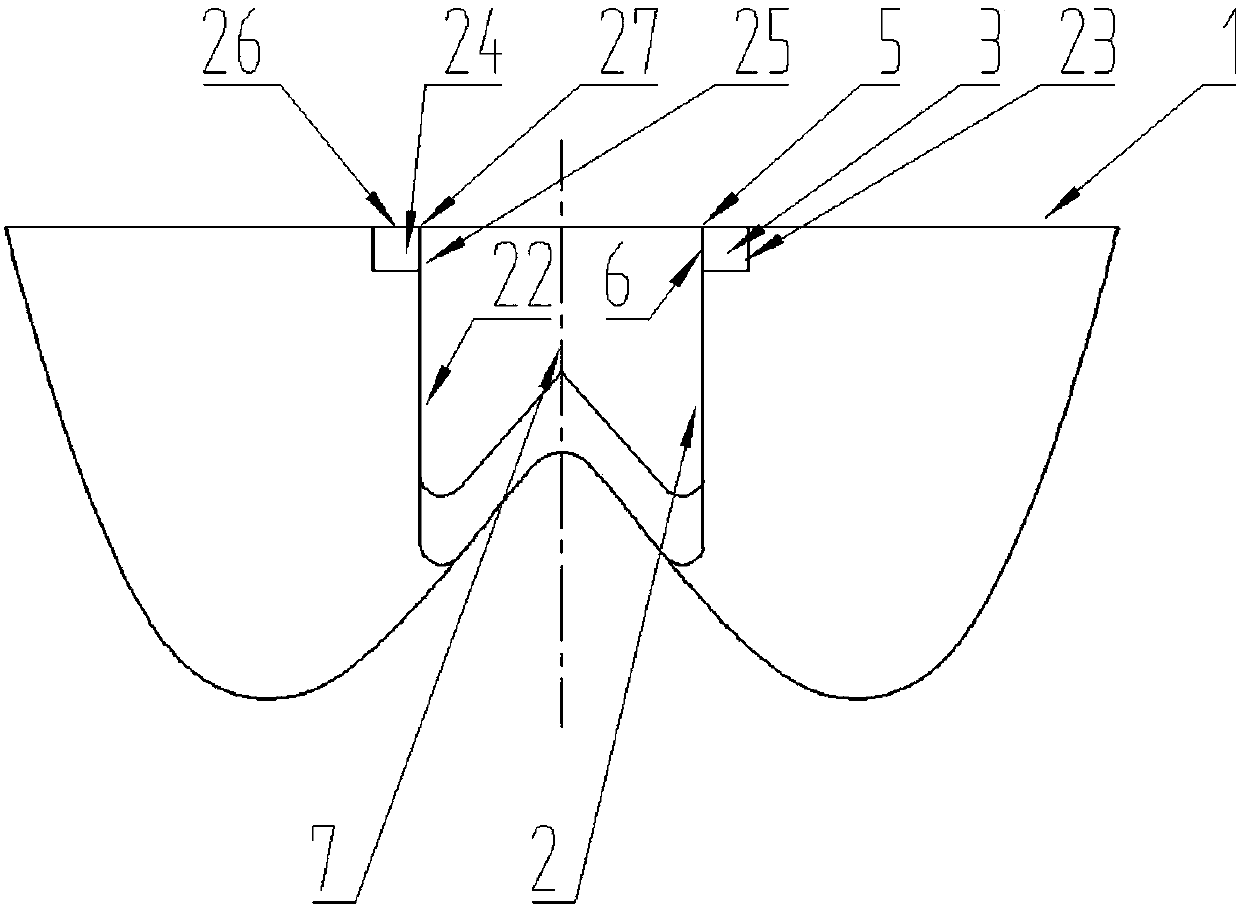

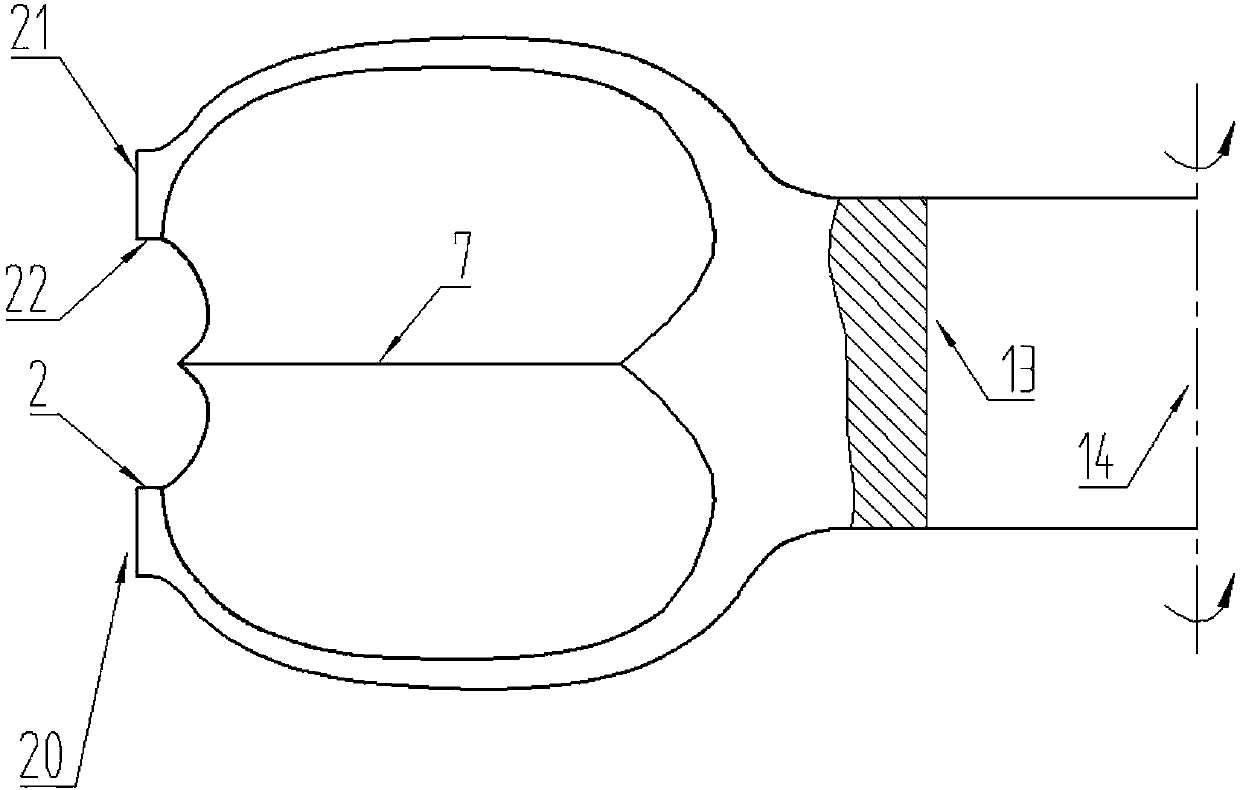

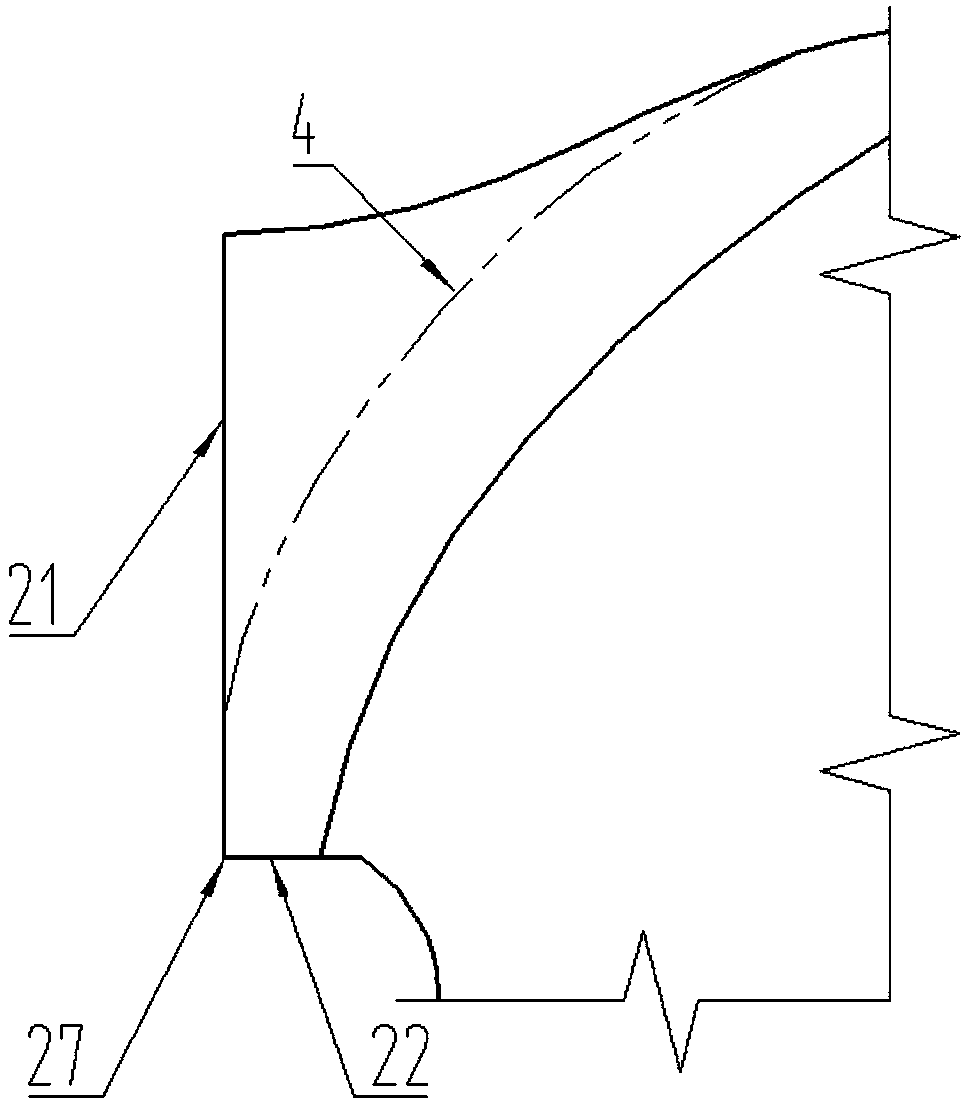

[0016] The measurement structure of the outer circle of a model runner of an impact type water turbine disclosed by the present invention is as follows: figure 1 and figure 2 As shown, at the position of the maximum outer circle diameter of each water bucket, two arc segments are extended from the back of the water bucket with the theoretical rotation center 14 of the impact runner as the rotation center, which is distributed symmetrically with respect to the water dividing edge 7: the first Arc segment 20 and the second arc segment 21, such as image 3 and Figure 4 As shown, the first arc segment 20 is located on the back surface 4 of the water bucket at the junction of the upper plane 1 of the water bucket and the outer facade 2 of the water cutting blade gap, and the second arc segment 21 is located outside the upper plane 1 of the water bucket and the water cutting blade gap On the back side 4 of the water bucket at the junction of the facade 22. Projections of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com