Circuit board resistance welding processing method

A processing method and circuit board technology, which is applied to the secondary treatment of printed circuits, coating of non-metallic protective layers, etc., can solve the problems of reducing processing time, insufficient solder mask thickness, and shortening the process flow, so as to reduce processing time and improve Bubble removal ability, the effect of solving insufficient solder mask thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

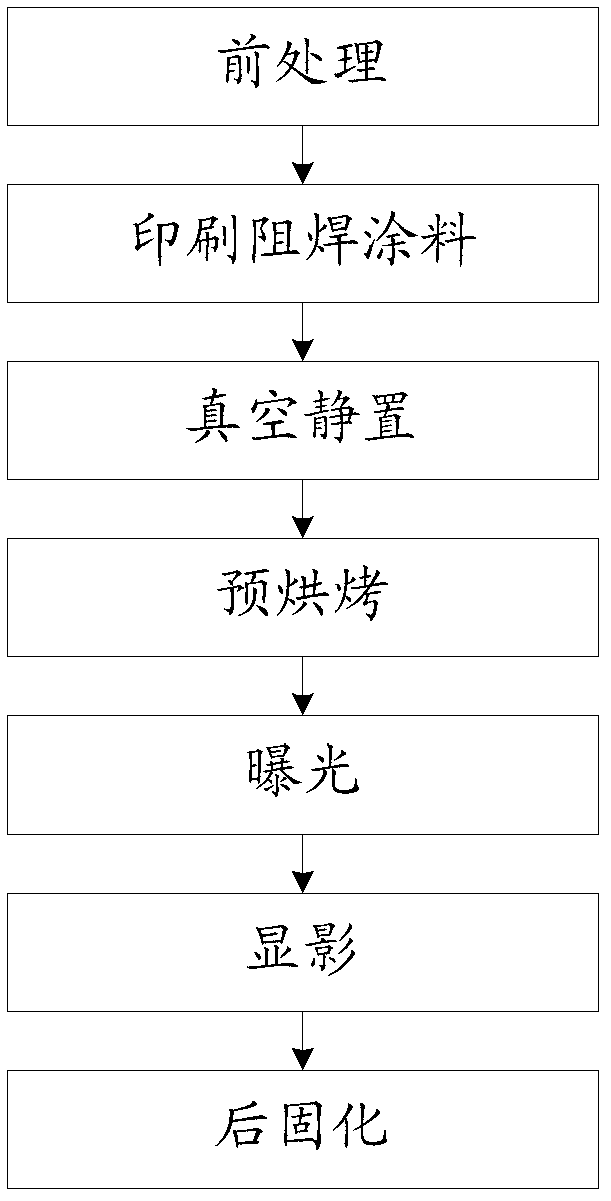

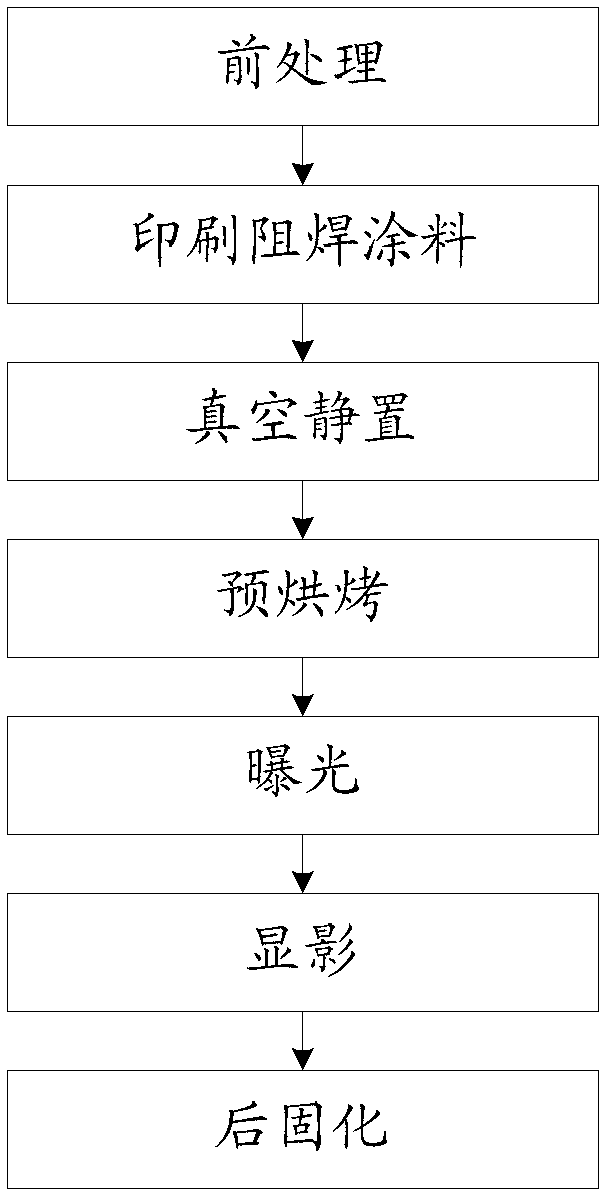

[0008] The embodiment of the present invention provides a solder resist processing method for circuit boards, which adopts the technical solution of standing still in vacuum, which can not only solve the problems of insufficient solder resist thickness and generation of air bubbles in solder resist processing of thick copper circuit boards, but also shorten the solder resistance. Welding process, reducing processing time. A detailed description will be given below in conjunction with the accompanying drawings.

[0009] At present, conventional circuit board solder resist processing methods for thick copper circuit boards usually include two solder resist processes, and each solder resist process includes the following steps:

[0010] Pre-treatment, printing solder mask, standing, pre-baking, exposure, development, post-curing.

[0011] In the first solder mask process, after performing the above-mentioned steps from pre-treatment to post-curing, enter the second solder mask p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com