Precoated fin material for heat exchangers and heat exchanger

A technology for heat exchangers and fins, which is applied in the field of pre-coated fin materials for heat exchangers, and can solve the problems of reduced air volume flowing into the heat exchanger, fin occlusion, and increased ventilation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

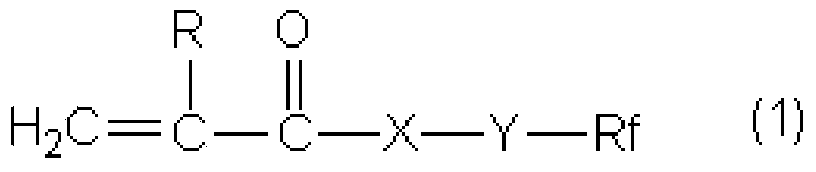

Method used

Image

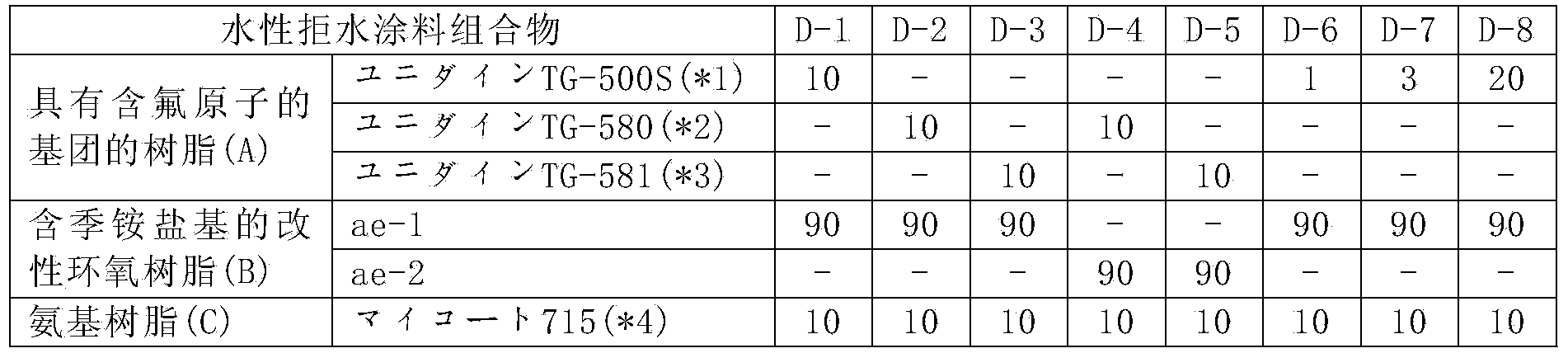

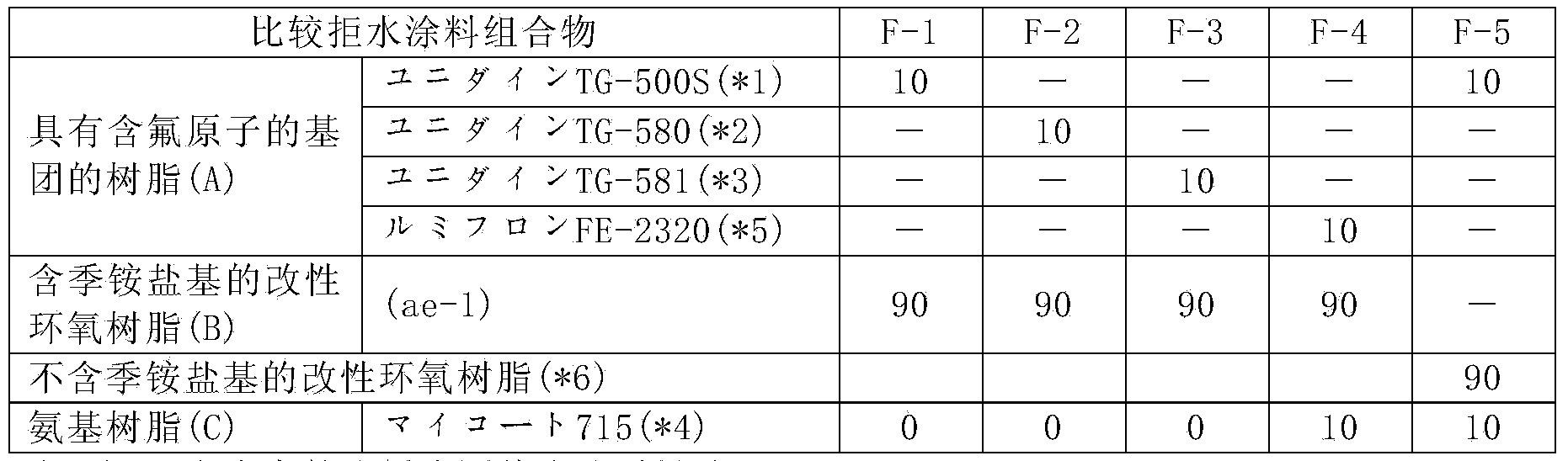

Examples

manufacture example

[0112] In the following production examples, "part" means a mass part, and "%" means a mass %.

[0113] (1) Production of carboxyl-containing acrylic resin (ca) used in the production of ammonium-containing modified epoxy resin (B)

manufacture example 1

[0114] [Manufacturing example 1: Solution of carboxyl group-containing acrylic resin (ca-1)]

[0115] Heat 850 parts of n-butanol to 100°C under a nitrogen stream, and add a monomer mixture and a polymerization initiator "450 parts of methacrylic acid, 450 parts of styrene, 100 parts of ethyl acrylate, peroxide - 40 parts of tert-butyl 2-ethylhexanoate", aging for 1 hour after dropping. Next, a mixed solution of 10 parts of tert-butyl peroxy-2-ethylhexanoate and 100 parts of n-butanol was added dropwise over 30 minutes, followed by aging for 2 hours after the dropwise addition. Next, 933 parts of n-butanol and 400 parts of ethylene glycol monobutyl ether were added to obtain a solution of a carboxyl group-containing acrylic resin (ca-1) having a solid content of about 30%. The obtained resin had a resin acid value of 300 mgKOH / g and a weight average molecular weight of about 17000.

manufacture example 2

[0116] [Manufacturing example 2: Solution of carboxyl group-containing acrylic resin (ca-2)]

[0117] Heat 1,400 parts of n-butanol to 100°C under nitrogen flow, and add the monomer mixture and the polymerization initiator "670 parts of methacrylic acid, 250 parts of styrene, 80 parts of ethyl acrylate, peroxide - 50 parts of tert-butyl 2-ethylhexanoate", aging for 1 hour after dropping. Next, a mixed solution of 10 parts of tert-butyl peroxy-2-ethylhexanoate and 100 parts of n-butanol was added dropwise over 30 minutes, followed by aging for 2 hours after the dropwise addition. Next, 373 parts of n-butanol and 400 parts of ethylene glycol monobutyl ether were added to obtain a solution of a carboxyl group-containing acrylic resin (ca-2) having a solid content of about 30%. The obtained resin had a resin acid value of 450 mgKOH / g and a weight average molecular weight of about 14000.

[0118] (2) Manufacture of modified epoxy resin (ae) containing ammonium base

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com