Preparation method for semiconductor sample of TEM

A sample preparation and semiconductor technology, which is applied in the field of semiconductors, can solve the problems of easy distortion and damage of TEM samples, low success rate, difficulty in meeting the thickness requirements of TEM samples, etc., and achieve the effect of improving the success rate of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

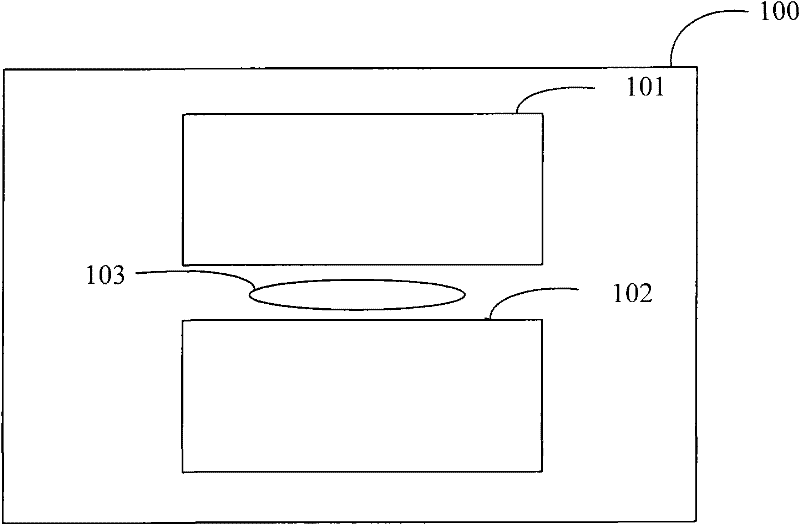

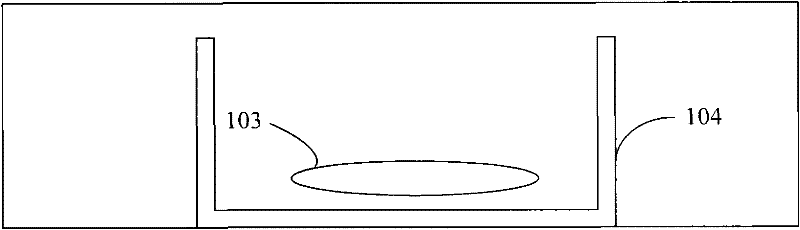

[0033] Putting the wafer into a focused ion beam machine, using a focused ion beam to form grooves on the wafer, the target structure is located between the two grooves, and the preparation method further includes:

[0034] Roughly cutting the sidewall parts of the two grooves close to the sample to obtain a sample containing the target structure;

[0035] cutting a lateral opening in the bottom of the sample to a length capable of isolating the target structure from the wafer;

[0036] Using a focused ion beam to remove semiconductor devices on the wafer above the target structure in the sample;

[0037] Finally, the focused ion beam is used to finely cut the side wall of one of the grooves close to the sample until the target structure is observed, and then finely polish the side wall of one of the grooves close to the sample until the thickness of the sample meets the requirements of the transmission electron microscope sample.

[0038] The thickness of the rough-cut sample ...

specific Embodiment 1

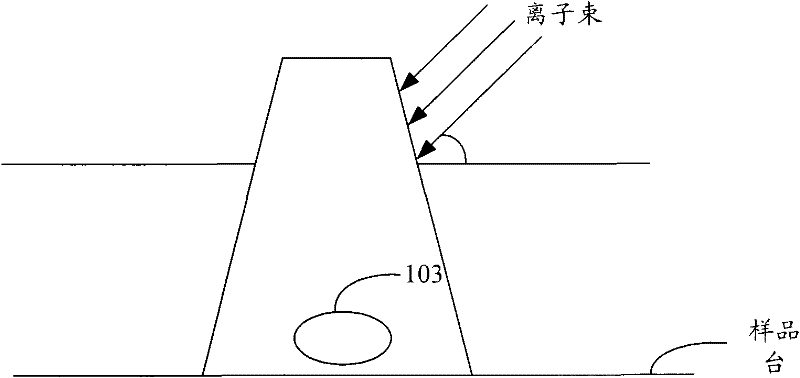

[0045] In conjunction with the TEM sample preparation flow chart of the present invention figure 2 and sample cross-sections during sample preparation image 3 In detail, the present invention uses the FIB machine with the FIB-SEM dual-beam system to carry out the TEM sample preparation method of the semiconductor device located at the bottom of the wafer, and the steps are as follows:

[0046] Step 201, place the wafer horizontally on the sample stage of the FIB machine with the FIB-SEM dual-beam system, and use a beam current range of 6000-8000 picoamps (pA) in the upper and lower symmetrical areas about 2 microns away from the target structure The I beam bombards to form a groove whose length is at least greater than the length of the target structure, the width ranges from 6 to 10 microns, and the height is at least exposing the entire target structure. The target structure is required to be located between two grooves. Among them, the position of the target structure h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com