Production method for transparent suboptical polyester film

A technology of polyester film, manufacturing method, applied in the direction of coating, etc., to achieve the effects of enhanced adhesion, strong adhesion, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

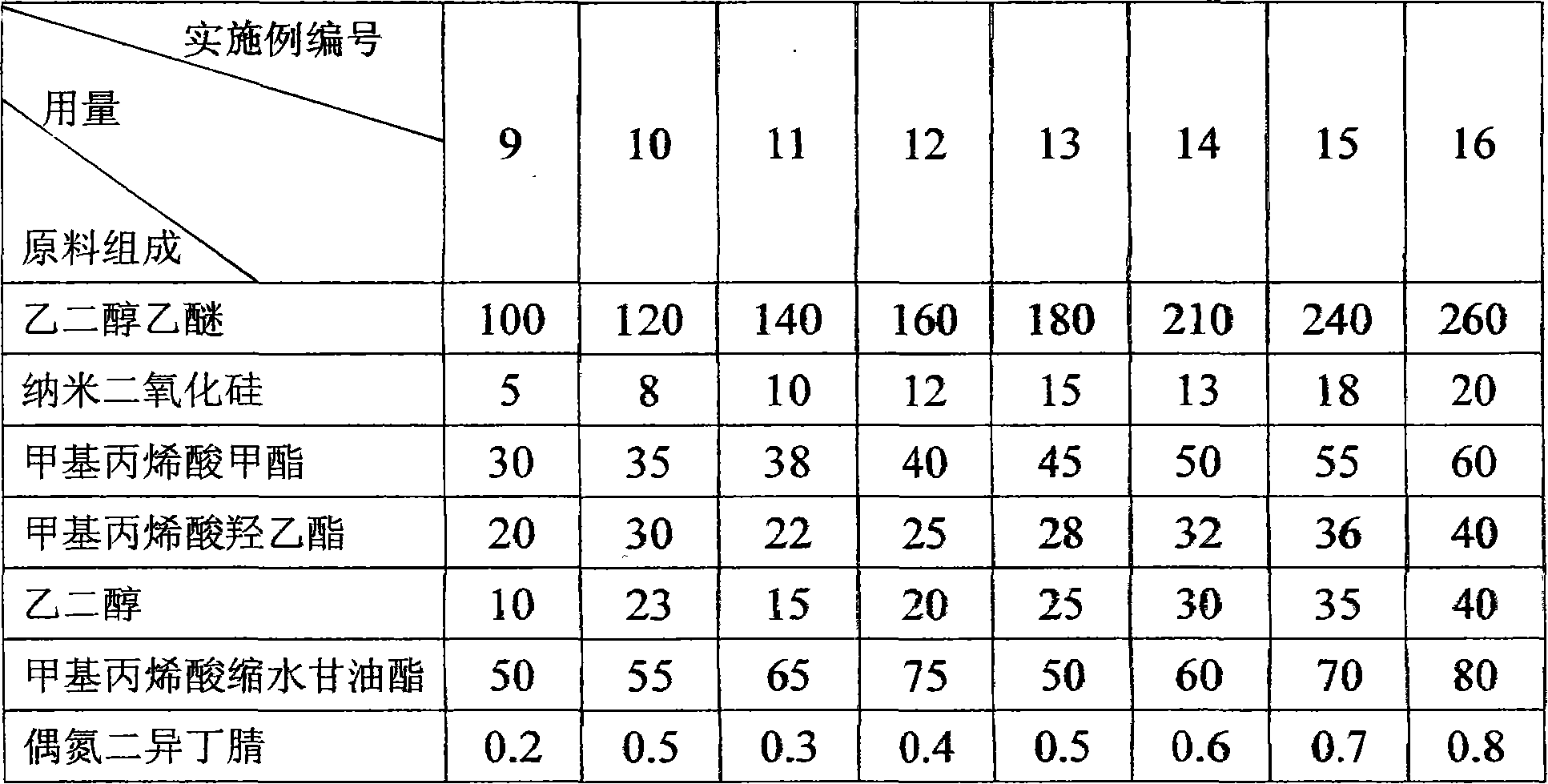

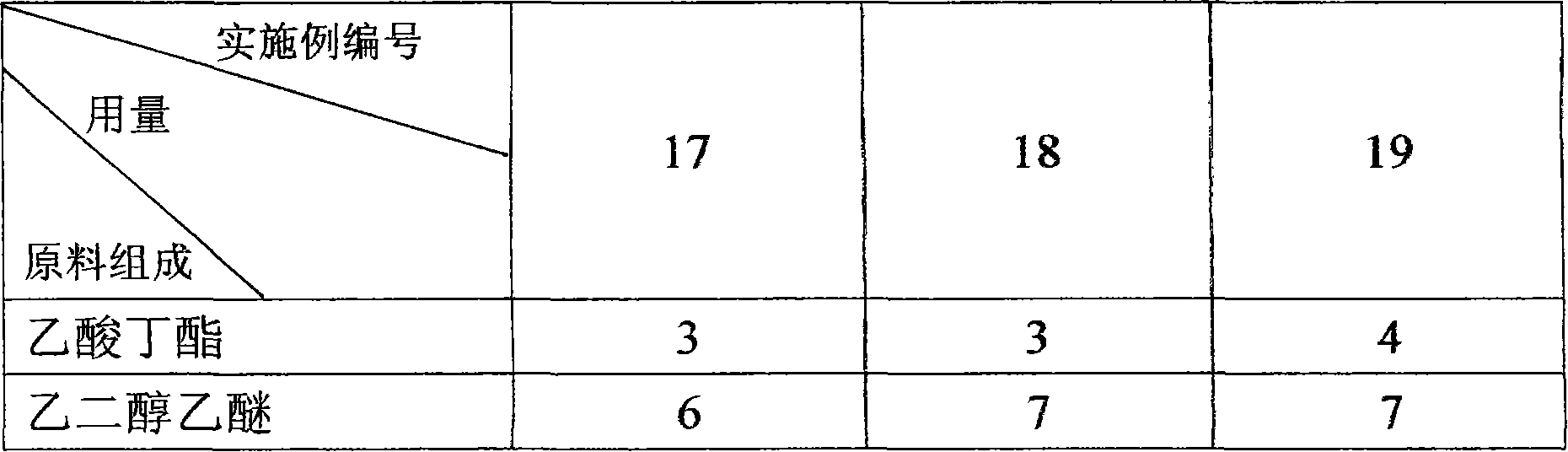

Examples

Embodiment 1

[0024] A method for manufacturing a transparent matt polyester film, the process steps of the method comprising: synthesizing an acrylic transparent matt resin, preparing an acrylic transparent matt resin solution, and preparing a transparent matt polyester film through a coating process;

[0025] The step of synthesizing acrylic transparent matt resin is to put 100g of ethylene glycol ether into a reaction kettle equipped with a stirrer and a reflux condensation device, and when the temperature reaches 80-100°C, start stirring and keep it at 1000-1300°C speed per minute, then add 5g of nano-silica within 20-50 minutes, and control the temperature rise, so that the temperature rises to 125-135°C when the nano-silica is added, and then add 30g of methyl The ethylene glycol of methyl acrylate, 10g, the hydroxyethyl methacrylate of 20g and the glycidyl methacrylate of 50g are stirred evenly, and nitrogen gas is passed into again, and the azobisisobutyronitrile of 0.2g is added aga...

Embodiment 2

[0030] A method for manufacturing a transparent matt polyester film, the process steps of the method comprising: synthesizing an acrylic transparent matt resin, preparing an acrylic transparent matt resin solution, and preparing a transparent matt polyester film through a coating process;

[0031] The step of synthesizing acrylic transparent matte resin is to put 100g of ethylene glycol ether into a 500ml three-neck flask equipped with a stirrer and a reflux condensing device, heat under reflux, and when the temperature rises to 80-100°C, start stirring And keep the speed at 1000-1300 rev / min, slowly add 5g of nano-silica in half an hour, and control the temperature rise, so that the temperature rises to 130°C when the nano-silica is added, and then add 30g of formazan methyl methacrylate, 20g hydroxyethyl methacrylate, 10g ethylene glycol, and 50g glycidyl methacrylate. After 5 minutes, the components have been stirred evenly, and then nitrogen gas is introduced. It is approp...

Embodiment 3

[0036] A method for manufacturing a transparent matt polyester film, the process steps of the method comprising: synthesizing an acrylic transparent matt resin, preparing an acrylic transparent matt resin solution, and preparing a transparent matt polyester film through a coating process;

[0037] The step of synthesizing acrylic transparent matte resin is to put 260g of ethylene glycol ether into a 1000ml three-neck flask equipped with a stirrer and a reflux condensing device, heat under reflux, and when the temperature rises to 80-100°C, start stirring And keep the speed at 1000-1300 rev / min, slowly add 20g of nano-silica in half an hour, and control the temperature rise, so that the temperature rises to 130°C when the nano-silica is added, and then add 60g of formazan Methyl methacrylate, 40g hydroxyethyl methacrylate, 40g ethylene glycol and 80g glycidyl methacrylate. After 5 minutes, the components have been stirred evenly, and then nitrogen gas is introduced. It is appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com