Light leaking prevention liquid crystal display

A liquid crystal display, anti-light leakage technology, applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of increasing production processes, difficult combination of backplane and plastic frame, affecting product quality, etc., to avoid light leakage, reasonable design, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

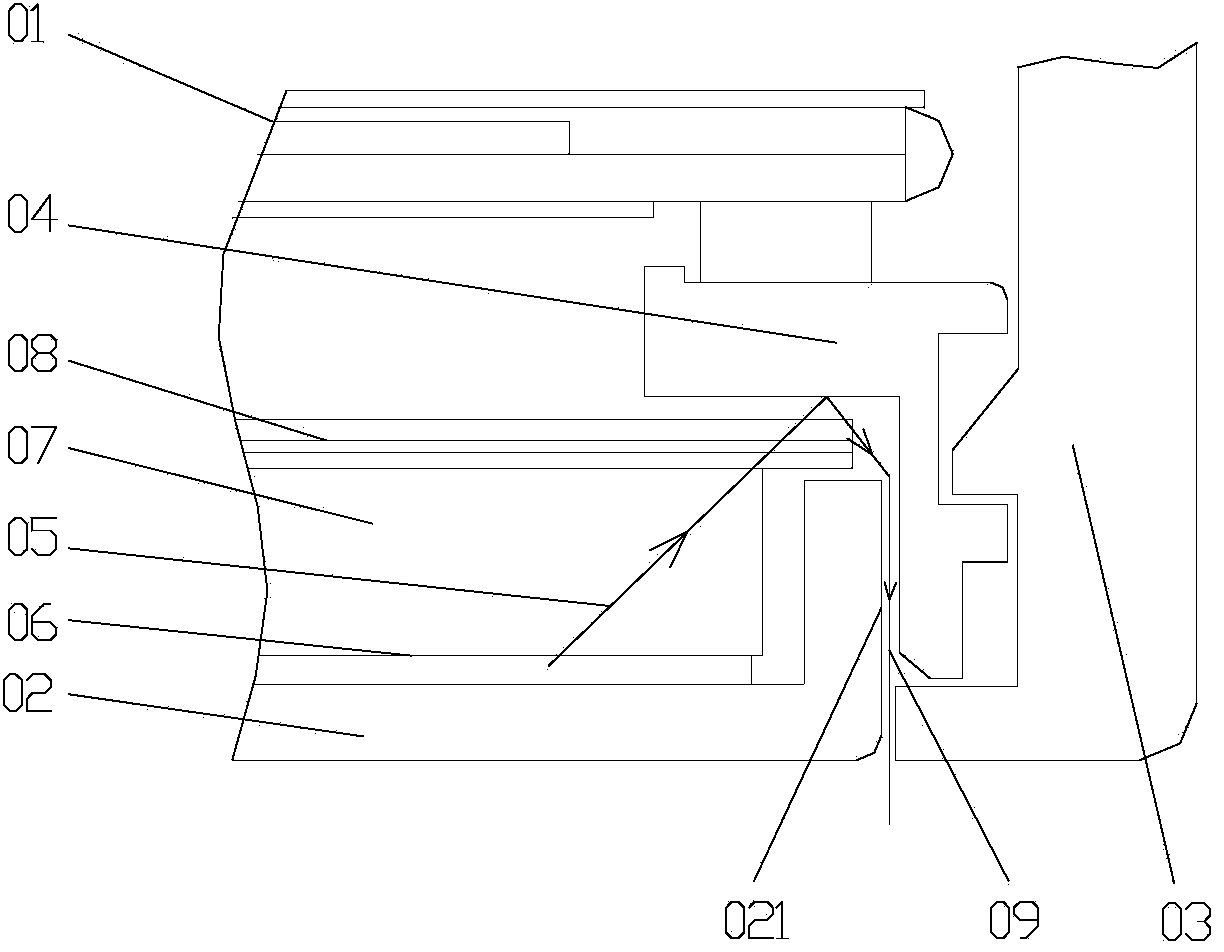

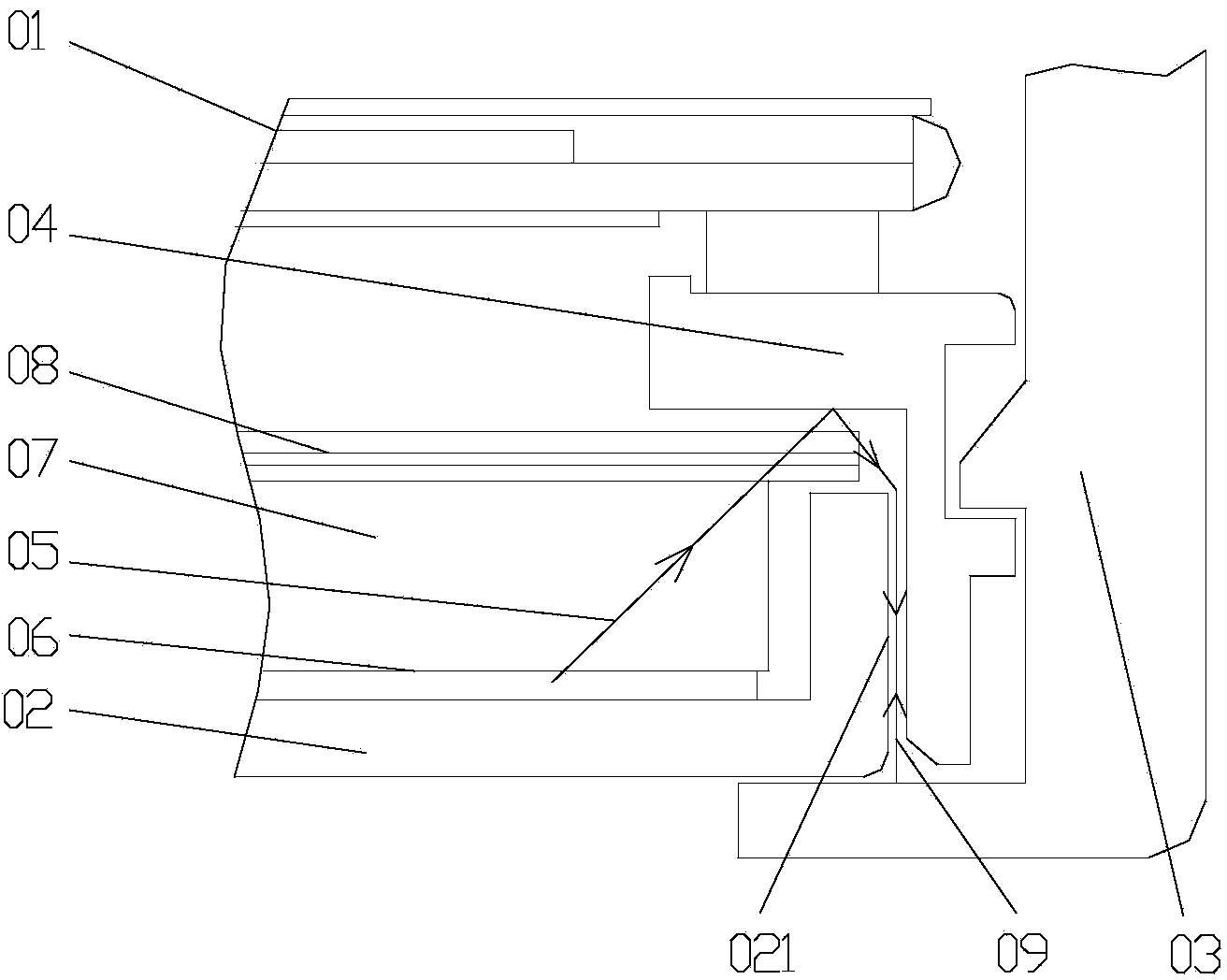

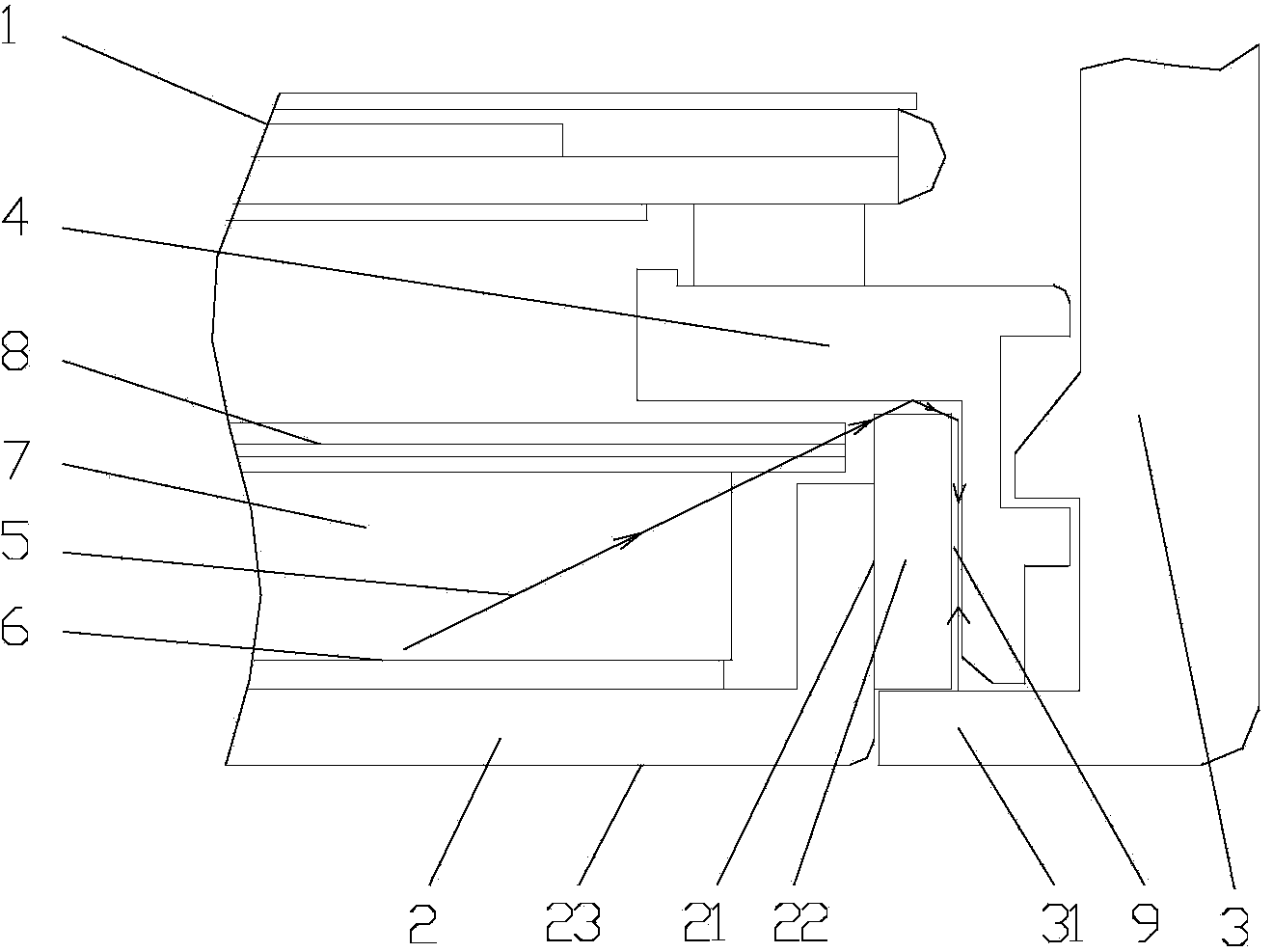

[0018] Such as image 3 As shown, the present invention includes a liquid crystal panel 1, a back plate 2, a middle frame 3 and a plastic frame 4. The back plate 2 is concave, and the back plate 2 is provided with a reflective sheet 6 and a guide in order from bottom to top. The light plate 7 and the optical film 8, the liquid crystal panel 1 is arranged above the optical film 8, the middle frame 3 is arranged outside the side 21 of the back plate, the plastic frame 4 is T-shaped, and the plastic frame 4 is arranged on Between the liquid crystal panel 1, the optical film 8, the side surface 21 of the back plate and the middle frame 3, the side surface 21 of the back plate is provided with a bending part 22, and the bottom end of the middle frame 3 is provided with an extension part 31, and the folding part The vertical distance between the end of the bent portion 22 corresponding to the bottom surface of the back plate 23 and the bottom surface 23 of the back plate is equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com