An optical lever measuring device

A measuring device and optical lever technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unfavorable laboratory utilization efficiency, large laboratory space, low measurement accuracy, etc., to improve space utilization, operation and performance. The effect of convenient reading and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

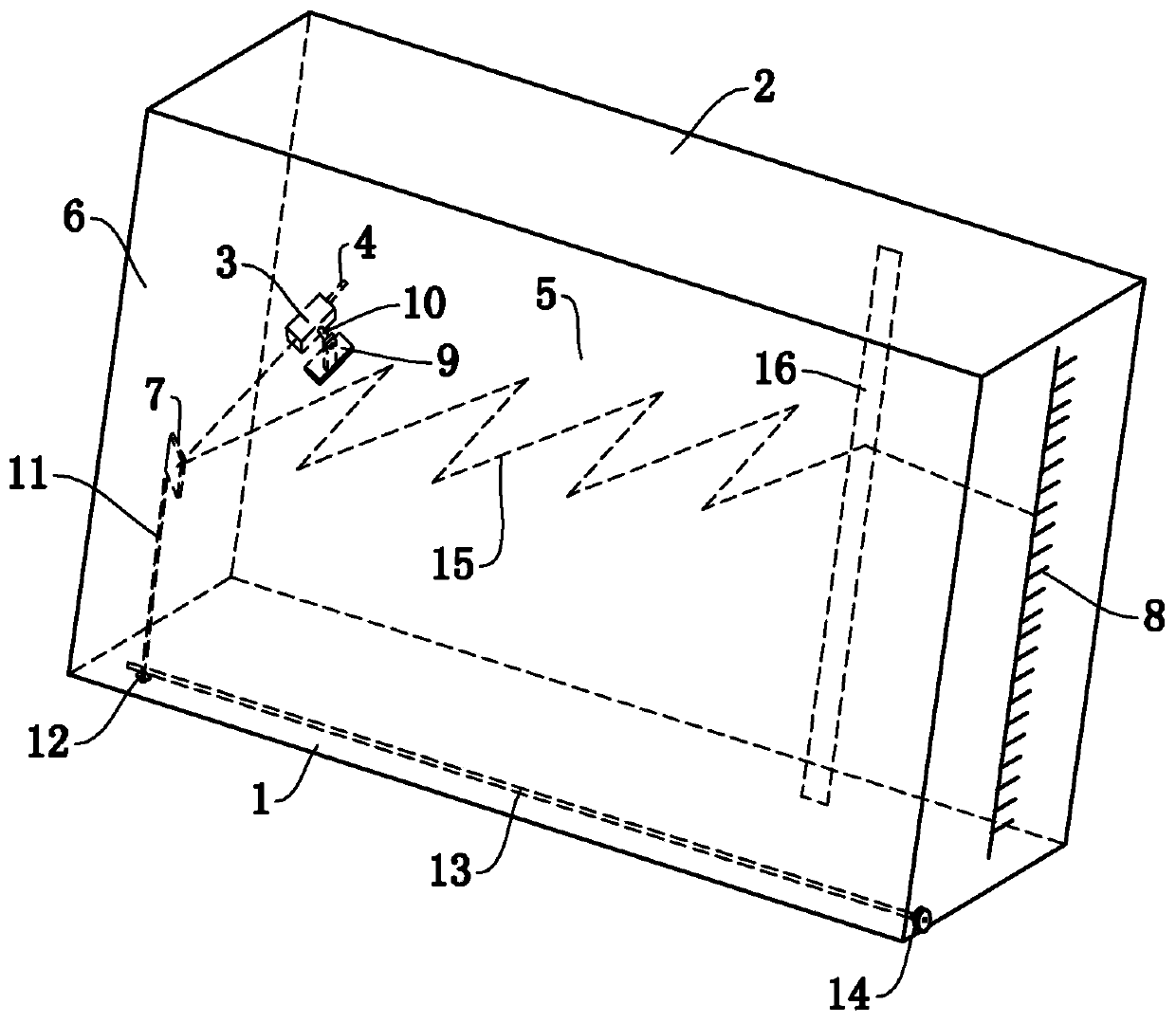

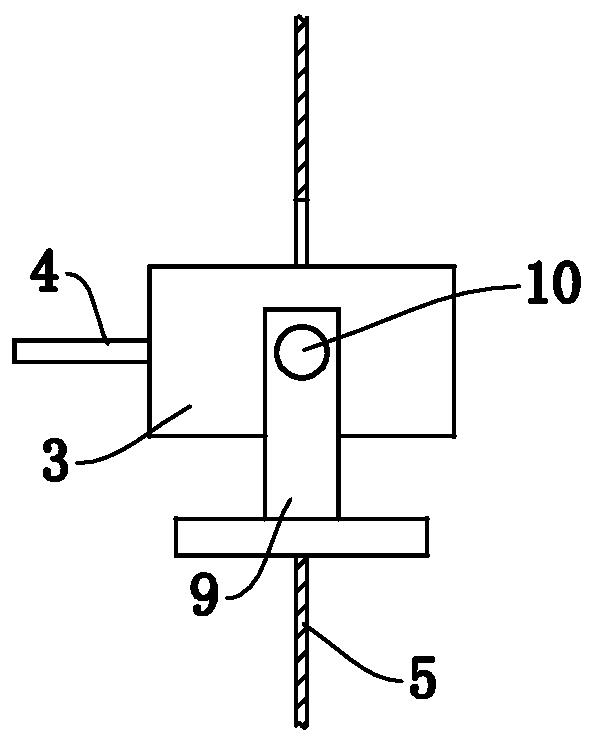

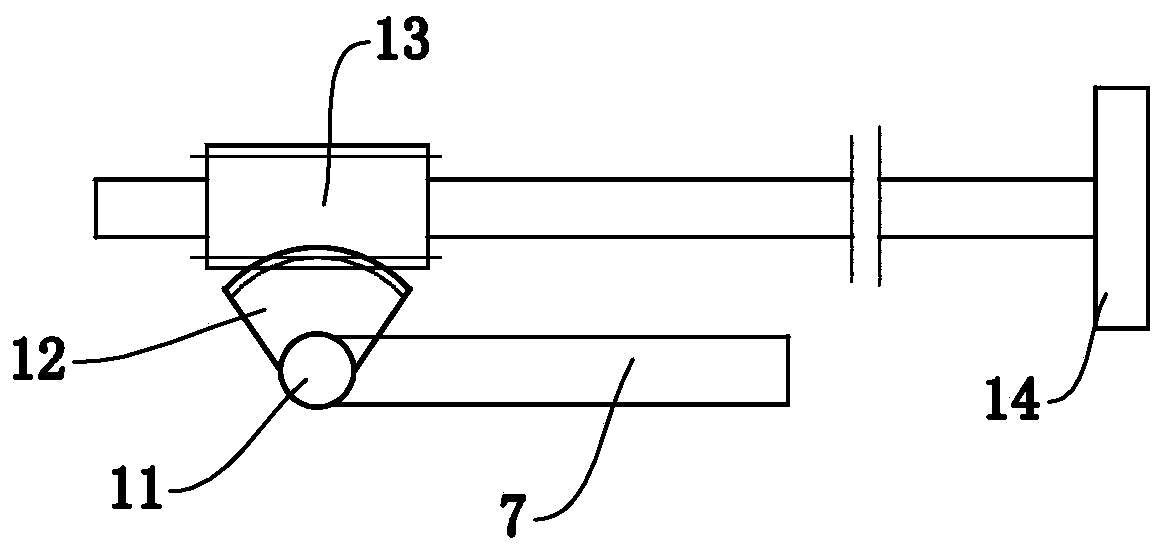

[0047] Such as Figure 1 to Figure 3 Commonly shown, a kind of optical lever measuring device, comprises base plate 1, top plate 2, laser device 3, support foot 4, the first reflection mirror 5 and the second reflection mirror 6 that are arranged parallel to each other, reflection mirror 7, display with scale Screen 8 and support 9, the first reflective mirror 5, the second reflective mirror 6 and the display screen 8 are all vertically arranged on the base plate 1, and the top plate 2 is arranged between the tops of the first reflective mirror 5 and the second reflective mirror 6 Between, the reflective surface of the first reflective mirror 5 and the reflective surface of the second reflective mirror 6 are oppositely arranged.

[0048] The support 9 is fixedly mounted on the first reflector 5, and a horizontal axis 10 is arranged between the laser 3 and the support 9. One end of the laser 3 is fixedly connected to the supporting foot 4, and the other end is a laser emitting ...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, the difference is that, as Figure 7 As shown, the top plate 2 is provided with a guide rail 18, of course, the guide rail 18 can also be installed on the base plate 1, the extension direction of the guide rail 18 is consistent with the extension direction of the first reflector 5, and the laser display position adjustment mirror 16 is slidably installed on the guide rail 18 on. In this way, the position of the laser display position adjustment mirror 16 can be changed conveniently, avoiding the problem that the laser light path deviates from the range of the laser display position adjustment mirror 16 due to changing the laser reflection angle.

[0064] The reflective surface of the laser display position adjustment mirror 16 is a plane, the guide rail 18 is provided with a slide block 19, an angle adjustment device 20 is provided between the laser display position adjustment mirror 16 and the slide block 19, and t...

Embodiment 3

[0068] This embodiment is basically the same as Embodiment 2, the difference is that, as Figure 9 As shown, the reflective surface of the laser display position adjustment mirror 16 is a vertically arranged cylindrical surface, and the laser inline display mirror 17 is not provided, so that the laser spot can be expanded in the horizontal direction of the display screen 8, which facilitates reading.

[0069] The optical lever measuring device provided by the embodiment of the present invention has high measurement accuracy; it is convenient to operate and read, and can observe the process of the change of the reading when the length of the object changes; the measurement efficiency is high; the occupied space is small, which is conducive to improving the space utilization of the laboratory Rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com