Double-layer megawave cleaning system

A cleaning system, double-layer technology, applied in cleaning methods and utensils, cleaning methods using liquids, electrical components, etc., to achieve the effects of improving utilization, reducing energy loss, and improving cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below in conjunction with specific embodiments:

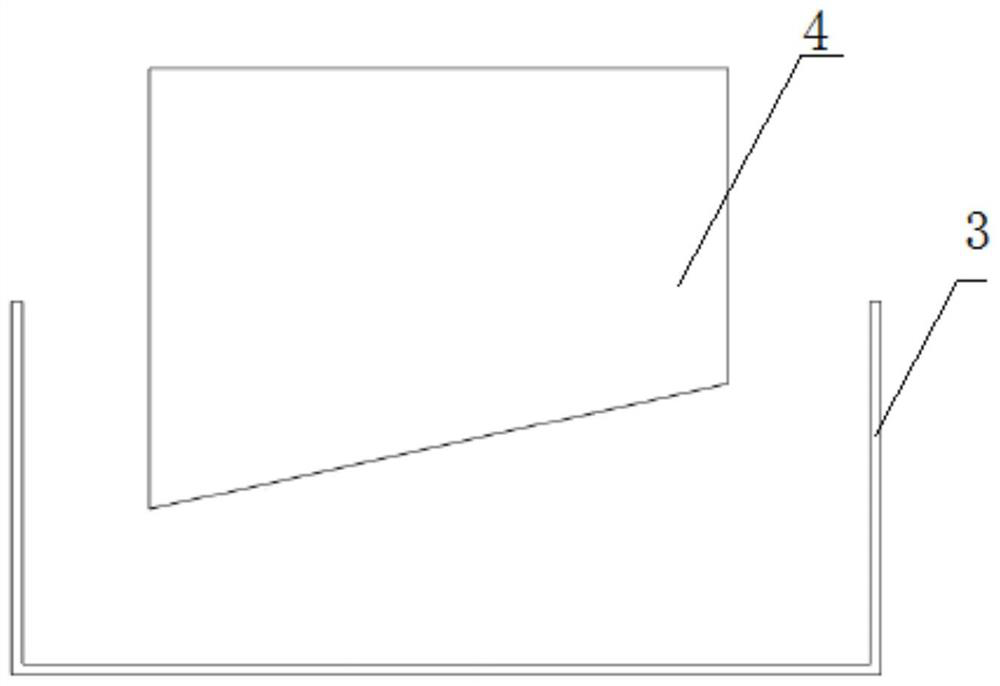

[0029] The cleaning of wafers by sound waves is widely used. Generally, the wafers in the cleaning tank are cleaned by the sound wave generator, and the lower end of the cleaning tank is immersed in the bath. The sound wave transmission medium is contained in the bath, and the sound wave is transmitted to Cleaning tank, but bubbles will gather at the bottom of the cleaning tank, and sound waves will be refracted and reflected when encountering bubbles, which will affect the energy of sound waves entering the cleaning tank; in order to solve this problem, the prior art uses the bottom of the cleaning tank as an inclined plane ,Such as image 3 As shown, air bubbles can move away from the bottom of the cleaning tank along the slope.

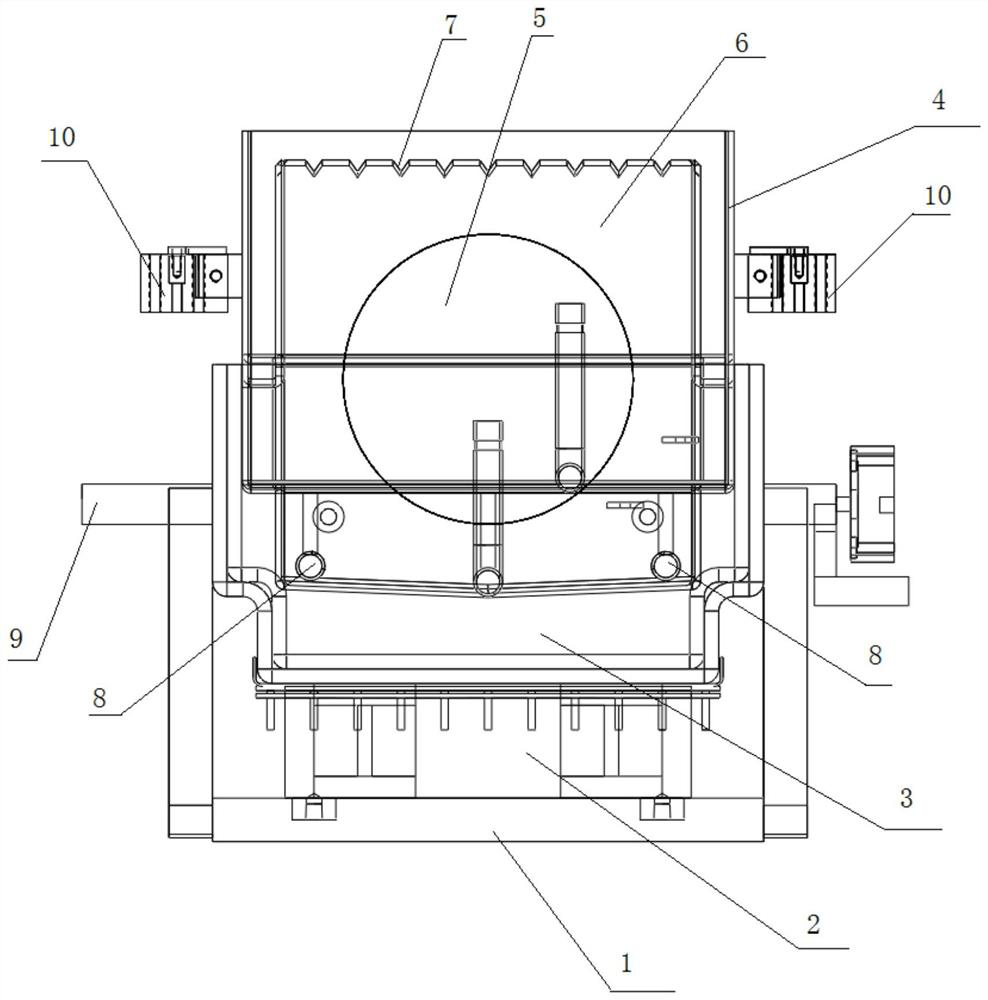

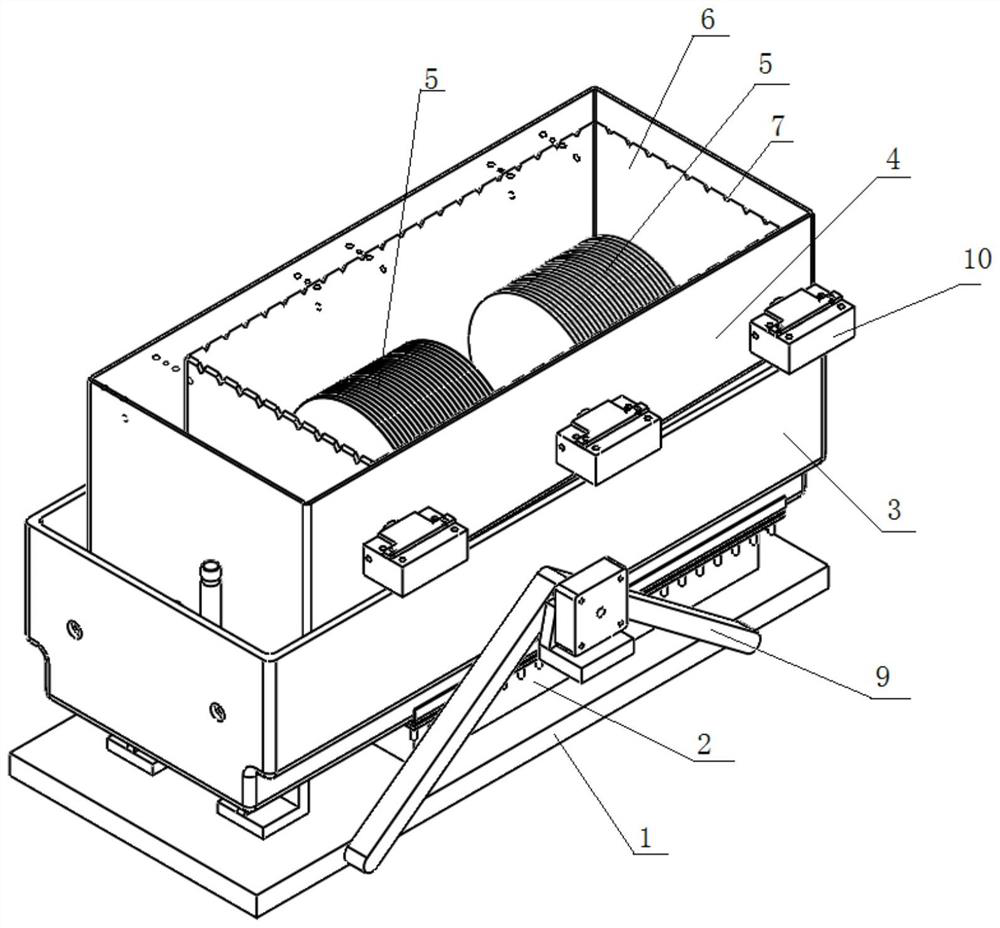

[0030] In order to solve this problem, this embodiment provides a double-layer megawave cleaning system, its structure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com