Contact type automatic ice and snow depth measuring method

A technology of contact measurement and automatic measurement, which is applied in the field of snow production and consumption monitoring and polar ice, can solve problems such as inability to determine timing and fixed points, heavy physical labor, and uncertain errors of physical detection technology, so as to solve uncertain error factors and carry Convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

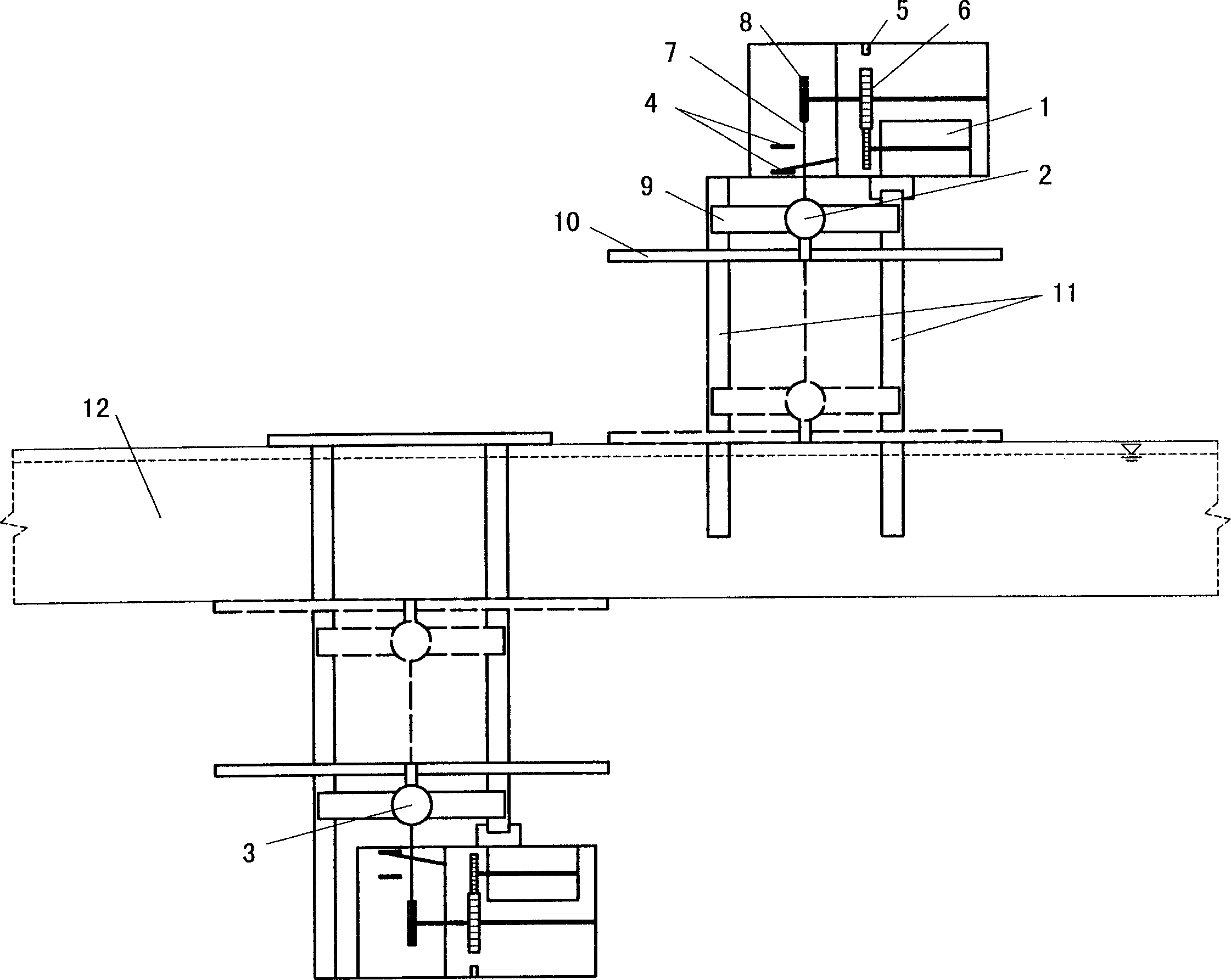

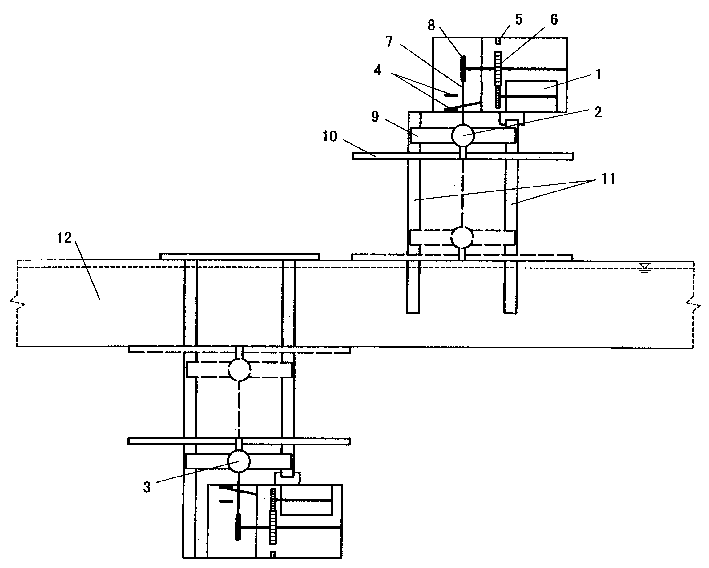

[0016] The method of using the zero-torque speed sensor to realize the contact-type automatic measurement of the ice and snow thickness change process, the specific implementation steps are as follows:

[0017] 1) Use Nanjing Sunshine 12V DC motor (1) as the power to drive the gravity probe (2) and buoyancy probe (3) to move.

[0018] 2) Use 2 HICKEY position sending sensors (4) produced by Wuxi Hengchang Automatic Control Equipment Co., Ltd. to determine the position of the ball probing action.

[0019] 3) Use a HCZ-A zero-torque speed sensor (5) produced by Wuxi Hengchang Automatic Control Equipment Co., Ltd. to record the movement distance of the mechanical gear (6) from the ice and snow interface to the reference point position; the single-chip microcomputer has a correction distance value The ability, its scope is 0-55 millimeter; The distance of every tooth movement on the gear (6) is 1mm.

[0020] 4) Probing balls (2), (3) are connected with rotating wheel (8) by non-s...

Embodiment 2

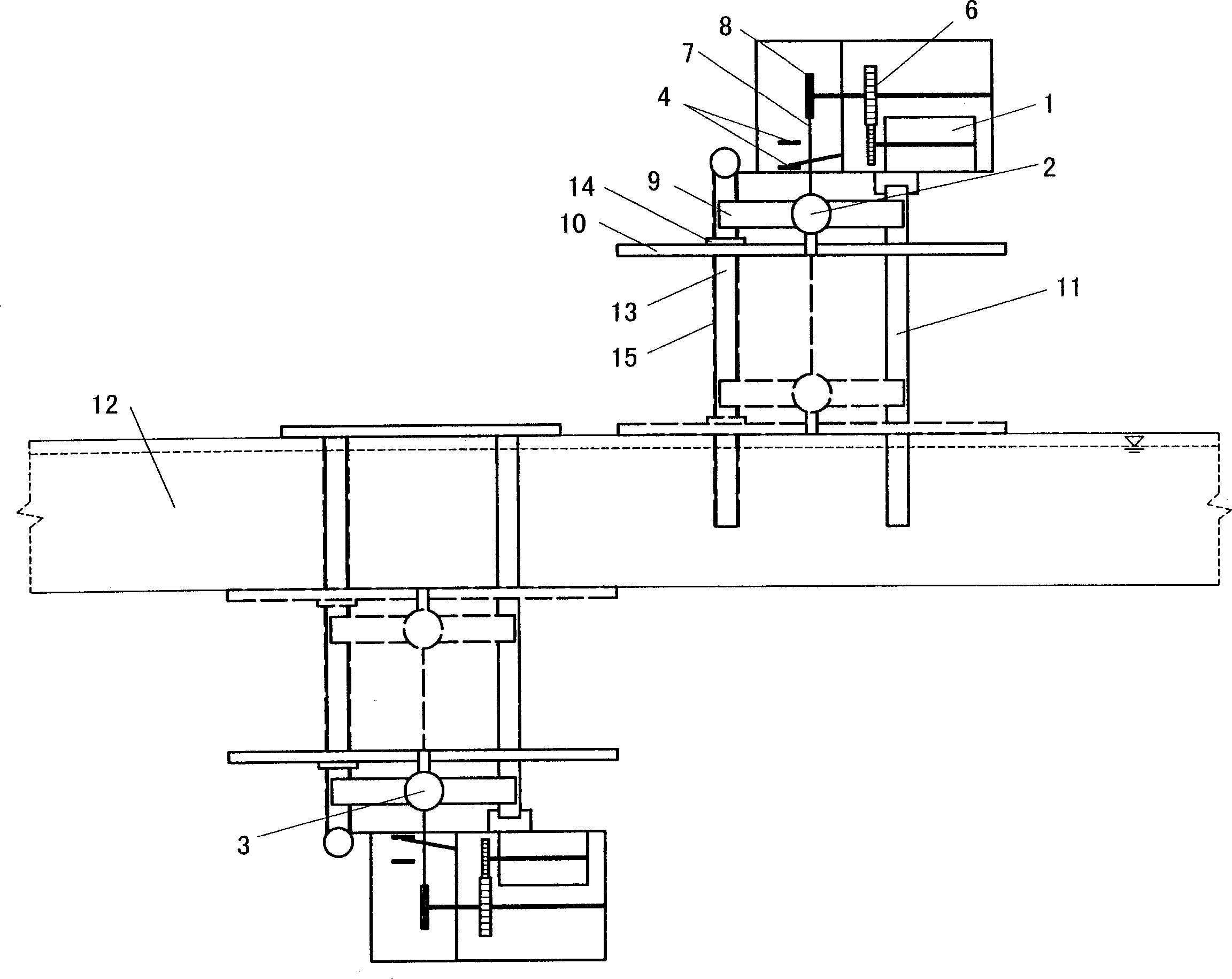

[0027] The method of using the magnetic displacement sensor to realize the contact automatic measurement of the ice and snow thickness change process, the specific implementation steps are as follows:

[0028] 1) Use Nanjing Sunshine 12V DC motor (1) as the power to drive the gravity probe (2) and buoyancy probe (3) to move.

[0029] 2) Use 2 HICKEY position sending sensors (4) produced by Wuxi Hengchang Automatic Control Equipment Co., Ltd. to determine the position of the ball probing action.

[0030] 3) Use a magnetic displacement sensor (13) as a support rod; the magnetic ring (14) is sleeved on the magnetic displacement sensor and fixed on the detection plate (10), and moves with the detection plate; record the magnetic ring from the ice 1. The movement distance of the snow interface reaching the reference point position; the single-chip microcomputer has the ability to correct the distance value, and its range is 0-55 millimeters; the movement distance of each tooth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com