Lignin/PVC decorative film sheet and preparation method thereof

A technology of lignin and decorative film, applied in the field of lignin/PVC decorative film and its preparation, can solve the problems of wear resistance, waste of resources, pollution of the environment, etc., and achieves good thermal stability, good effect and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

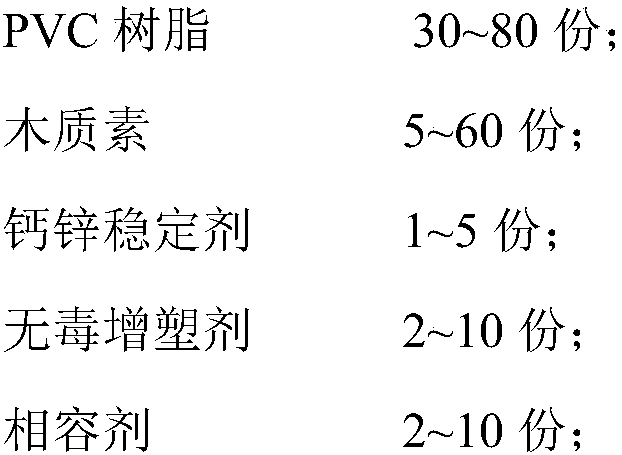

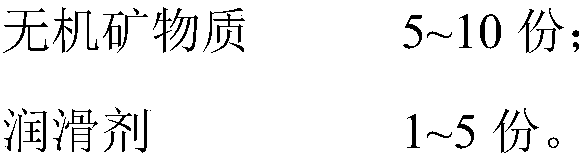

Method used

Image

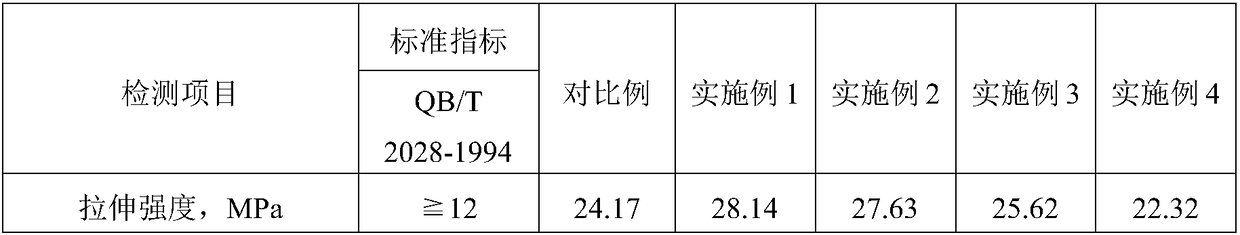

Examples

Embodiment 1

[0031] A lignin / PVC decorative film, which comprises the following components in parts by weight: 70 parts of PVC resin, 5 parts of lignin, 5 parts of compatibilizer (maleic anhydride grafted EVA), 5 parts of calcium zinc stabilizer , 5 parts of plasticizer (epoxidized soybean oil), 5 parts of inorganic mineral (calcium carbonate), 5 parts of lubricant (stearic acid).

[0032] The preparation method of lignin / PVC decorative film of the present invention comprises the following steps:

[0033] (1) Preparation of lignin: drying, pulverizing and sieving the lignin in the papermaking black liquor to obtain 300 mesh lignin powder;

[0034] (2) Hot mixing and cold mixing of raw materials: PVC resin, lignin powder, calcium zinc stabilizer, non-toxic plasticizer (epoxy soybean oil), compatibilizer (maleic anhydride grafted EVA), inorganic minerals (calcium carbonate), lubricant (stearic acid), put them in the mixer according to the proportion and heat mix them for 30 minutes, mix and...

Embodiment 2

[0038] A lignin / PVC decorative film, which comprises the following components in parts by weight: 65 parts of PVC resin, 10 parts of lignin, 5 parts of compatibilizer (maleic anhydride grafted EVA), 5 parts of calcium zinc stabilizer , 5 parts of plasticizer (epoxidized soybean oil), 5 parts of inorganic mineral (calcium carbonate), 5 parts of lubricant (stearic acid).

[0039] Embodiment 2 preparation method is the same as embodiment 1.

Embodiment 3

[0041] A lignin / PVC decorative film, which comprises the following components in parts by weight: 60 parts of PVC resin, 15 parts of lignin, 5 parts of compatibilizer (maleic anhydride grafted EVA), 5 parts of calcium zinc stabilizer , 5 parts of plasticizer (epoxidized soybean oil), 5 parts of inorganic mineral (calcium carbonate), 5 parts of lubricant (stearic acid).

[0042] Embodiment 3 preparation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com