Composite type rope and production process thereof

A production process and composite technology, applied in the field of ropes, can solve the problems of elevator sudden drop, easy to be stretched, easy to break, etc., and achieve the effect of simple production process steps, avoiding carbon fiber breakage, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

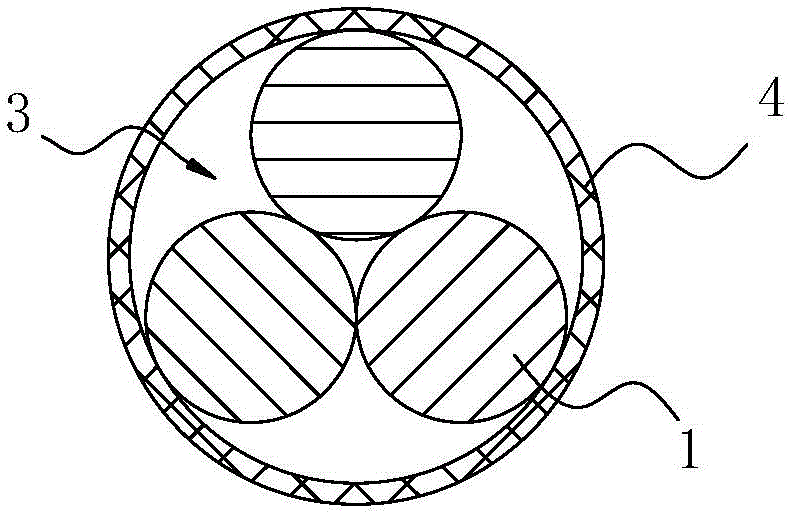

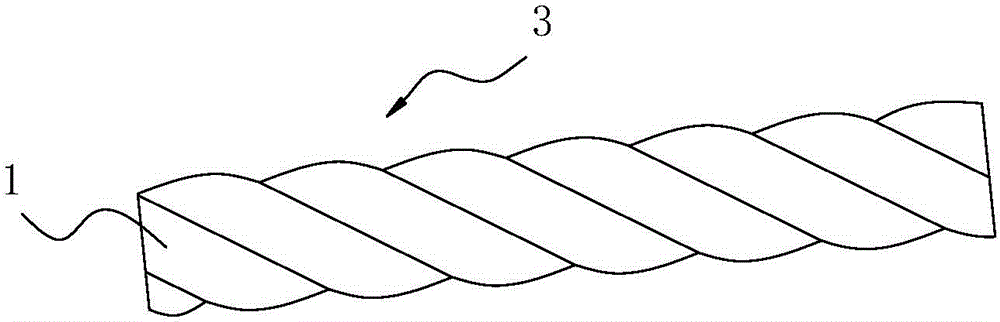

[0033] Such as figure 1 , 2 As shown, in this embodiment, a composite rope according to the present invention includes a carbon fiber rope core 3 composed of several carbon fiber bundles 1, and the carbon fiber rope core 3 is coated with aramid fiber made of aramid fiber material. cladding. In this embodiment, the carbon fiber rope core 3 is made by twisting three strands of carbon fiber bundles 1, and the aramid layer 4 is a mesh structure, which is sheathed on the surface of the carbon fiber rope core 3. The composite type described in this embodiment The diameter of the rope is 10 mm.

[0034] In order to improve the utilization rate of the fiber strength of the carbon fiber, the twist number of the carbon fiber bundle in this embodiment is 15n / m, and the inclination in the plying operation is 4.5 degrees.

[0035] Introduce below the production technology of composite type rope described in the present embodiment, it mainly comprises the following steps:

[0036] Step ...

Embodiment 2

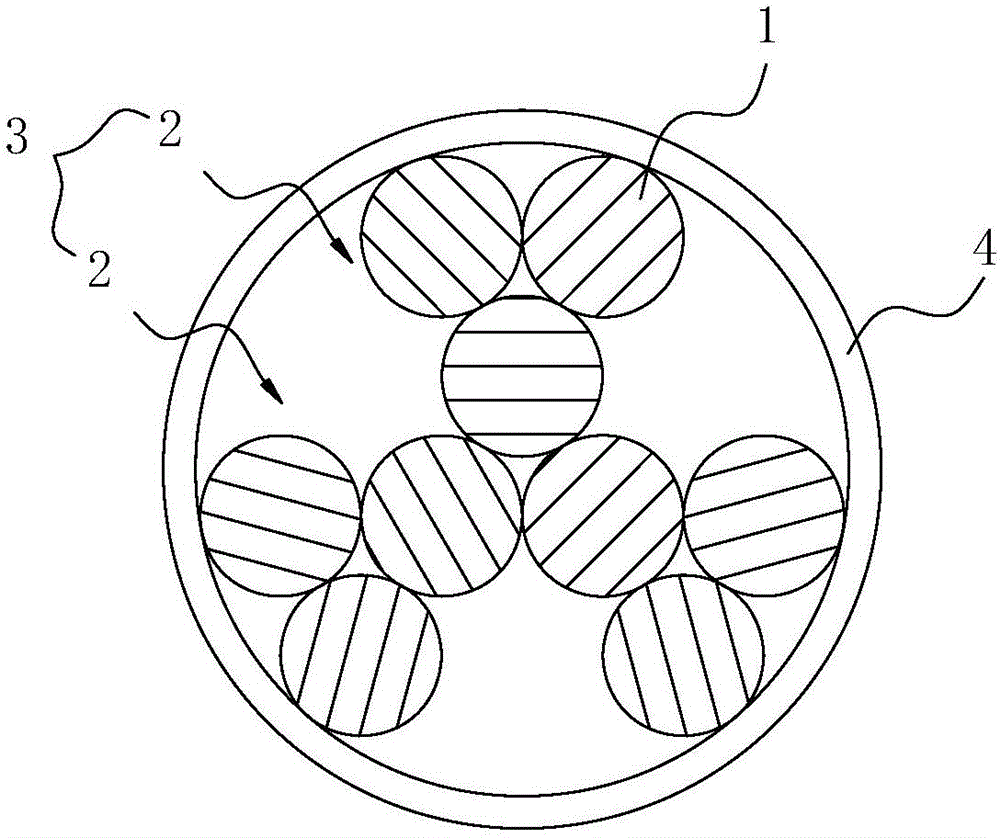

[0043] Such as image 3 As shown, in this embodiment, a composite rope according to the present invention includes a carbon fiber rope 2 composed of several carbon fiber bundles 1, and then several carbon fiber rope cores 3 composed of carbon fiber ropes 2, and wrapped outside the carbon fiber rope core 3 Covered with aramid covering made of aramid material. In this embodiment, the carbon fiber rope 2 is made of carbon fiber bundles 1 by twisting, the carbon fiber rope core 3 is made of three carbon fiber ropes 2 by twisting, and the aramid layer 4 has a mesh structure and is set on The surface of the carbon fiber rope core 3 forms a composite rope with a diameter of 10 mm.

[0044] The production technology of composite rope described in the present embodiment, comprises the following steps:

[0045] Step S10, carbon fiber rope core 3 processing: carbon fiber bundle 1 is used to manufacture carbon fiber rope 2 by twisting, and three carbon fiber ropes 2 are used to manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com