Multifunctional anticorrosion, waterproof and heat insulation paint and preparation method thereof

A thermal insulation coating and multi-functional technology, applied in the field of coatings, can solve the problems of low tensile strength and elongation at break of coatings, low wear resistance of waterproof and anti-corrosion coatings, and can not achieve multi-purpose use of one material, and achieve enhanced insulation. Heat and heat resistance effect, good heat insulation effect, effect of enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

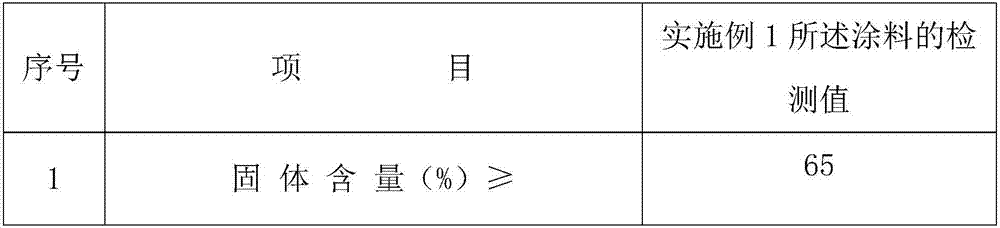

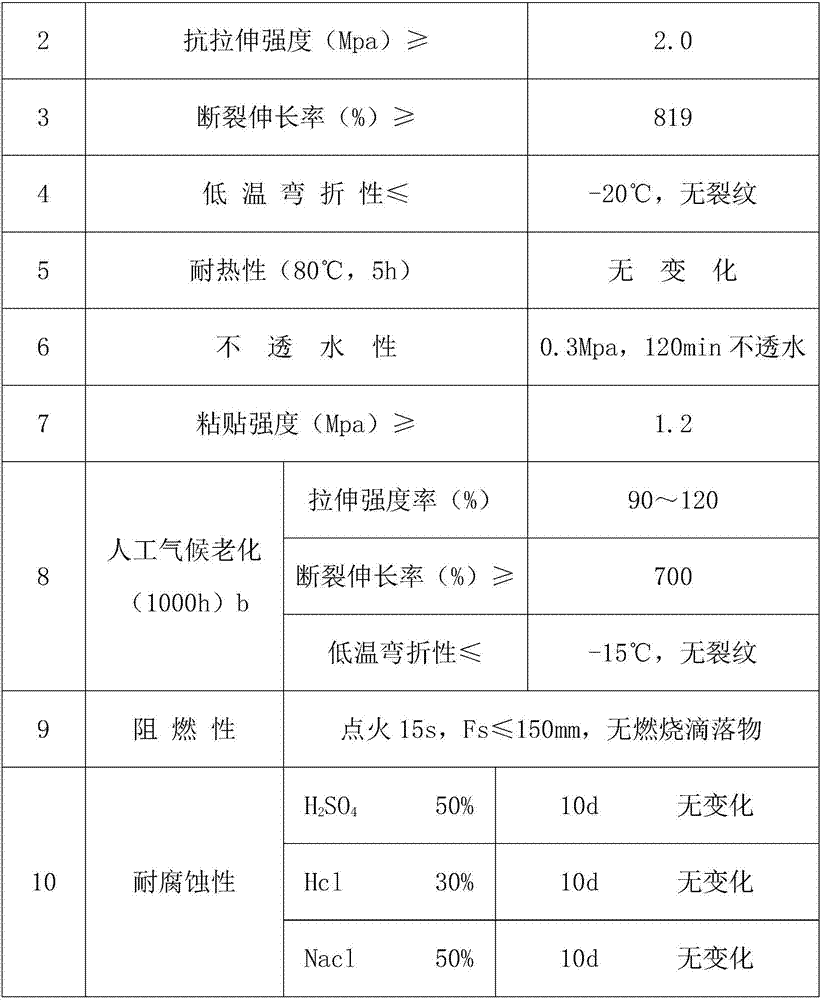

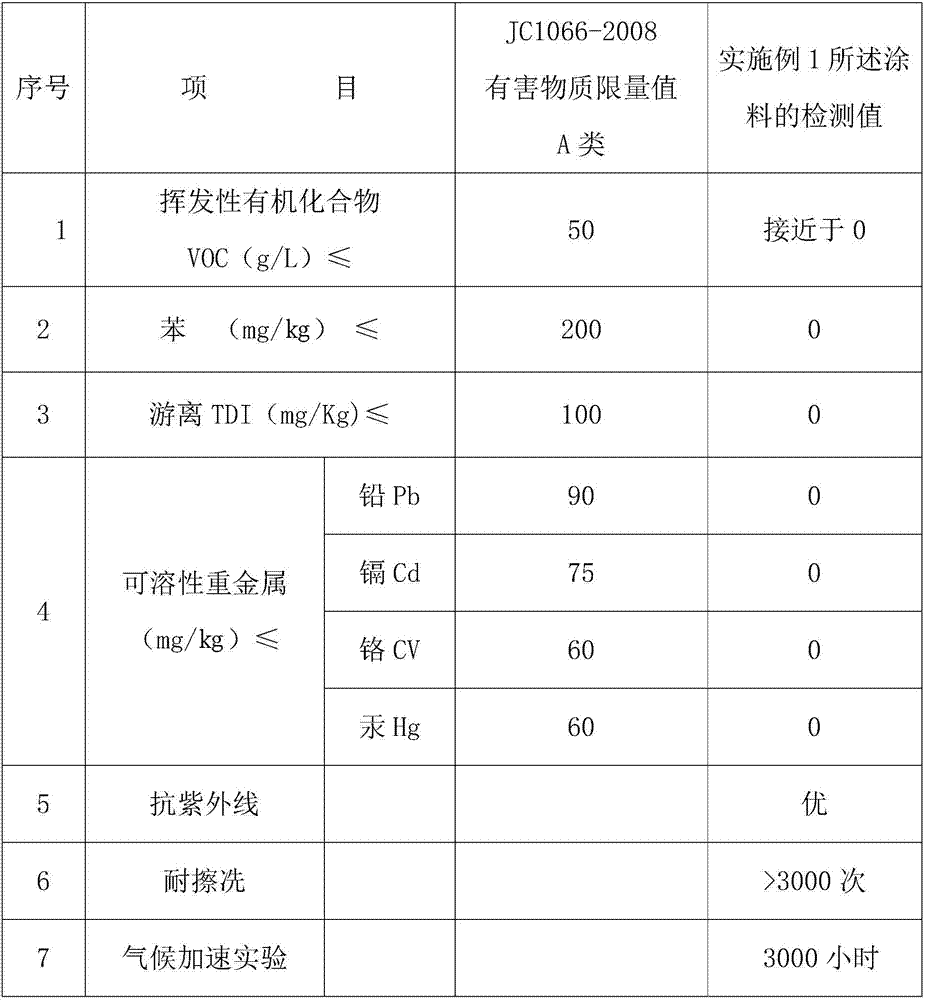

Embodiment 1

[0046] Weigh the following raw materials by weight: 170 parts of DM-HX68 synthetic latex, 380 parts of CM201, 710 parts of BJ-707 ethylene-vinyl acetate copolymer, 690 parts of DA-102 ethylene-vinyl acetate copolymer, 30 parts of vinyl resin, 12 parts of polyvinyl alcohol emulsion, 12 parts of AMP-95, 6.5 parts of sodium vinyl sulfonate, 9 parts of SN-5040, 22 parts of NXZ, 36 parts of ethylene glycol, 100 parts of dioctyl phthalate, 5 parts of IC303 , 5 parts of titanium dioxide, 20 parts of coal gangue powder, 0.6 parts of graphene, 5 parts of ammonia water , 22 parts of silica sol, 10 parts of hollow microspheres, 6 parts of nano-zinc oxide, 700 mesh high-frequency porcelain powder 120 parts, 500 parts of 700 mesh silica powder, 800 parts of 800 mesh heavy calcium carbonate powder, 140 parts of 400 mesh talc powder, 10 parts of high acid-resistant cast stone powder, 14 parts of TEXANOL, 4 parts of color paste, water-soluble cellulose ether 5 parts, 1160 parts of water.

[...

Embodiment 2

[0055] Weigh the following raw materials by weight: 150 parts of DM-HX68 synthetic latex, 350 parts of CM201, 600 parts of BJ-707 ethylene-vinyl acetate copolymer, 600 parts of DA-102 ethylene-vinyl acetate copolymer, 20 parts of vinyl resin, 10 parts of polyvinyl alcohol emulsion, 10 parts of AMP-95, 5 parts of sodium vinyl sulfonate, 7 parts of SN-5040, 15 parts of NXZ, 30 parts of ethylene glycol, 70 parts of dioctyl phthalate, 3 parts of IC303 , 3 parts of titanium dioxide, 15 parts of coal gangue powder, 0.5 parts of graphene, 3 parts of ammonia , 15 parts of silica sol, 15 parts of hollow microspheres, 3 parts of nano-zinc oxide, 700 mesh high-frequency porcelain powder 100 parts, 400 parts of 700 mesh silica powder, 700 parts of 800 mesh heavy calcium carbonate powder, 120 parts of 400 mesh talc powder, 15 parts of high acid-resistant cast stone powder, 10 parts of TEXANOL, 3 parts of color paste, water-soluble cellulose ether 3 parts, 1000 parts of water.

[0056] Pre...

Embodiment 3

[0064] Weigh the following raw materials by weight: 200 parts of DM-HX68 synthetic latex, 450 parts of CM201, 800 parts of BJ-707 ethylene-vinyl acetate copolymer, 800 parts of DA-102 ethylene-vinyl acetate copolymer, 40 parts of vinyl resin, 20 parts of polyvinyl alcohol emulsion, 15 parts of AMP-95, 10 parts of sodium vinyl sulfonate, 15 parts of SN-5040, 30 parts of NXZ, 40 parts of ethylene glycol, 120 parts of dioctyl phthalate, 37 parts of IC3037, 10 parts of titanium dioxide, 30 parts of coal gangue powder, 2 parts of graphene, 7 parts of ammonia water , 30 parts of silica sol, 20 parts of hollow microspheres, 10 parts of nano-zinc oxide, 150 parts of 700-mesh high-frequency porcelain powder Parts, 600 parts of 700 mesh silica powder, 900 parts of 800 mesh heavy calcium carbonate powder, 170 parts of 400 mesh talc powder, 20 parts of high acid-resistant cast stone powder, 15 parts of TEXANOL, 10 parts of color paste, 7 parts of water-soluble cellulose ether parts, 1200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com