Preparation method of high-strength foam concrete

A foam concrete, high-strength technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of low strength and poor hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

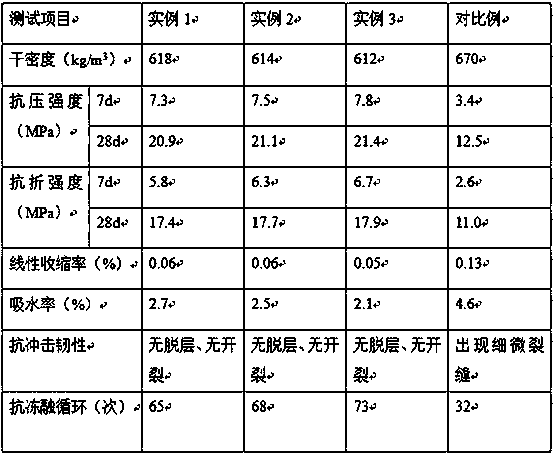

Examples

example 1

[0025] Diatomite and volcanic rock are poured into the pulverizer according to the mass ratio of 1:1, and after pulverizing for 30 minutes, pass through a 100-mesh sieve, collect the sieved powder, and set aside; the soybean oil and the ethanol solution with a mass fraction of 30% are Pour 1:1 into the stirrer, stir for 10 minutes, let it stand for stratification, and collect the lower ethanol phase; mix the standby sieved powder with the above ethanol phase at a mass ratio of 2:1 to obtain a mixture, pour it into the fermenter, and pour it into the The mass fraction of adding 6% of the mixture mass in the fermenter is 10 5 cfu / mL yeast suspension, add 10% distilled water of the mixture mass at the same time, seal and ferment for 1 week, obtain the modified inorganic substance, and set aside; cut the bamboo into short pieces, put them into the steam explosion tank of the steam explosion device, Introduce steam preheated to 200°C into the steam explosion tank until the pressure...

example 2

[0027] Diatomite and volcanic rock are poured into the pulverizer according to the mass ratio of 1:1, and after pulverizing for 35 minutes, they are passed through a 100-mesh sieve, and the sieved powder is collected for later use; the soybean oil and the ethanol solution with a mass fraction of 30% are Pour 1:1 into the stirrer, stir for 13 minutes, let it stand for stratification, and collect the lower ethanol phase; mix the spare sieved powder with the above ethanol phase at a mass ratio of 2:1 to obtain a mixture, pour it into the fermenter, and pour it into the The mass fraction of adding 6% of the mixture mass in the fermenter is 10 5cfu / mL yeast suspension, add distilled water with 13% of the mixture mass at the same time, seal and ferment for 1 week, obtain modified inorganic substances, and set aside; cut bamboo into short pieces, put them into the steam explosion tank of the steam explosion device, Introduce steam preheated to 225°C into the steam explosion tank unti...

example 3

[0029] Diatomite and volcanic rock are poured into the pulverizer according to the mass ratio of 1:1, and after crushing for 40 minutes, they are passed through a 100-mesh sieve, and the sieved powder is collected for later use; the soybean oil and the ethanol solution with a mass fraction of 30% are Pour 1:1 into the stirrer, stir for 15 minutes, let it stand for stratification, and collect the lower ethanol phase; mix the spare sieved powder with the above ethanol phase at a mass ratio of 2:1 to obtain a mixture, pour it into the fermenter, and pour it into the The mass fraction of adding 7% of the mixture mass in the fermenter is 10 6 cfu / mL yeast suspension, add distilled water with 15% of the mass of the mixture at the same time, seal and ferment for 2 weeks to obtain modified inorganic substances, and set aside; cut bamboo into short pieces, put them into the steam explosion tank of the steam explosion device, Introduce steam preheated to 250°C into the steam explosion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com