Flexible gradient strain film, preparation method and application thereof

A strained film and gradient technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of small test space, insufficient placement of tensile fixtures, and inability to have different tensile strains, and achieves a simple preparation process. Easy to use and resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a flexible gradient strain film, comprising the following steps:

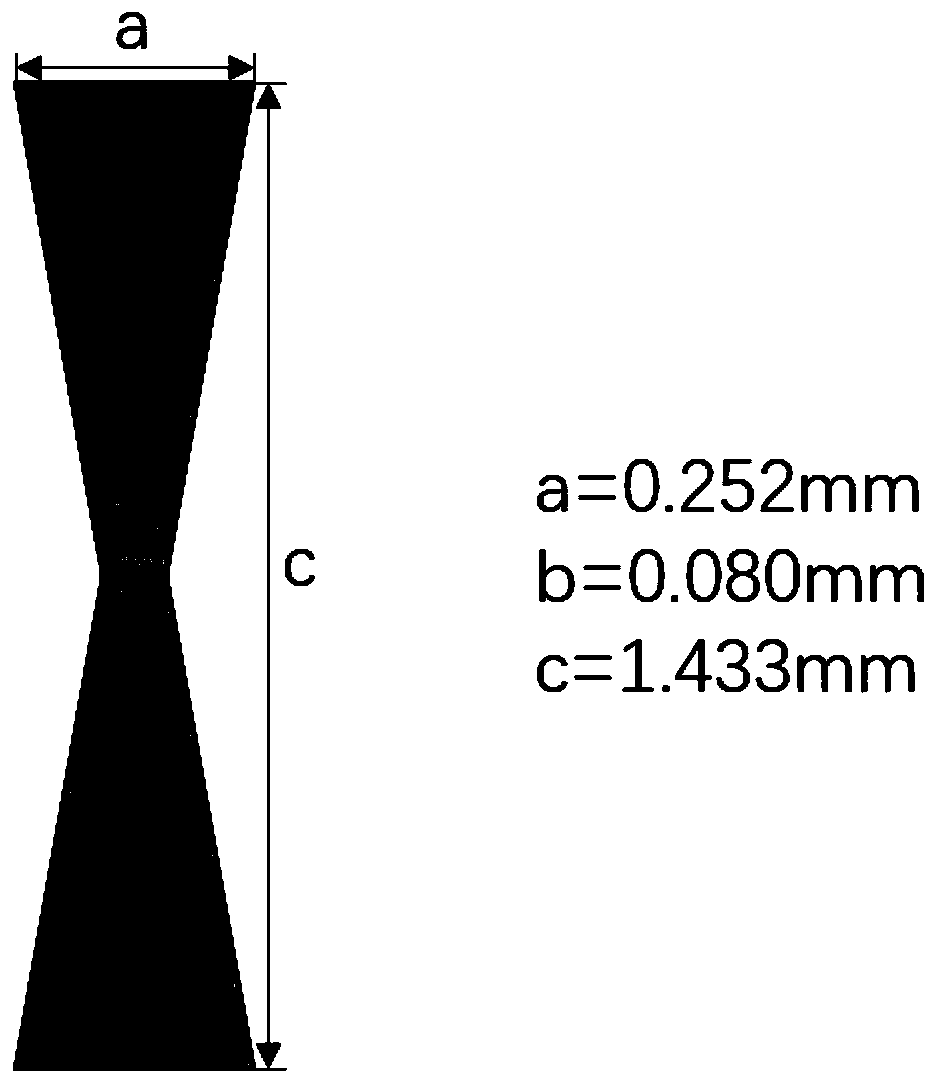

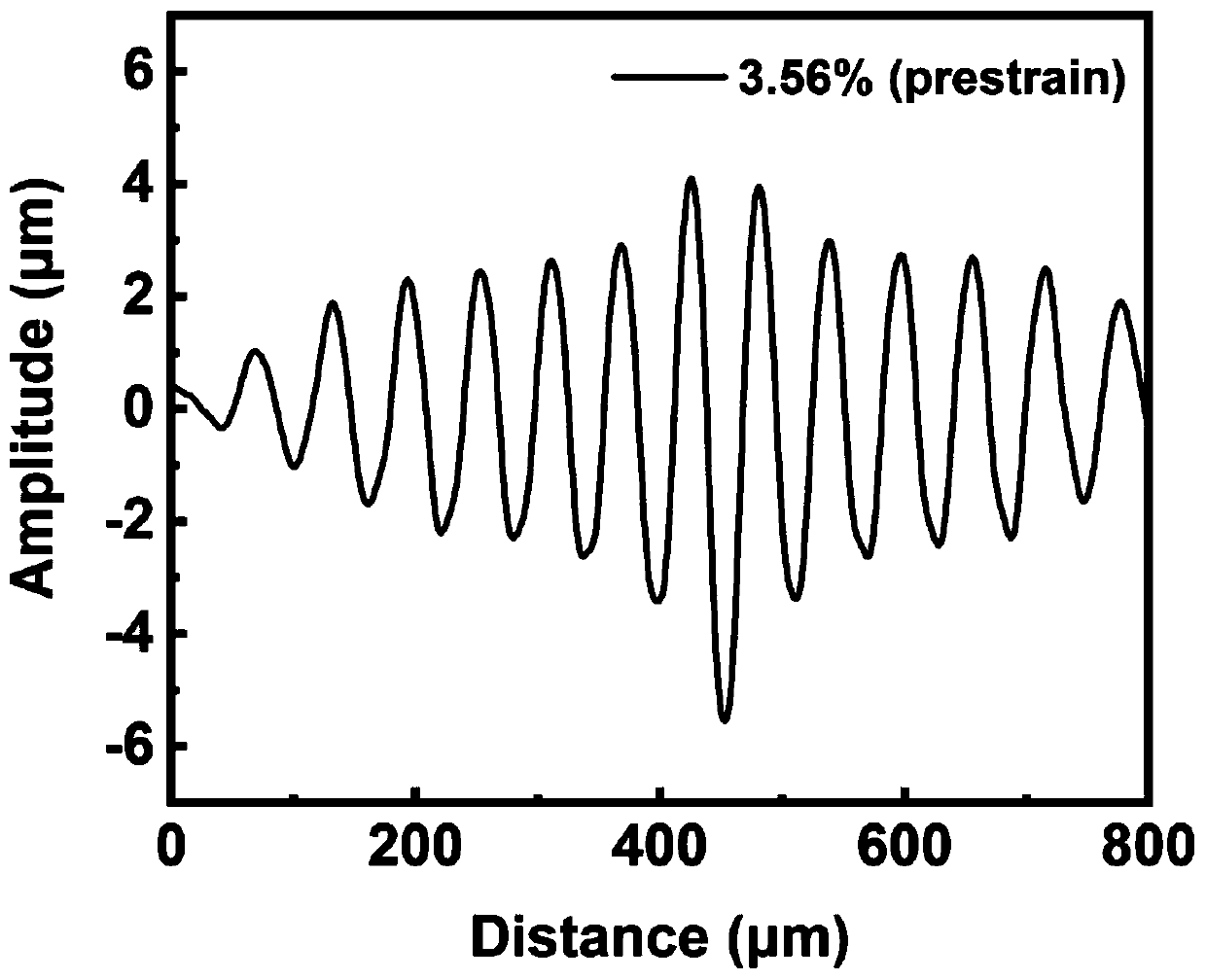

[0030] Step 1. Use AZ6112 positive resist as a mask, photolithography exposure time 3.5s, development 45s, prepare two isosceles trapezoidal patterns on the surface of the SOI substrate, the two isosceles trapezoids are isosceles trapezoids symmetrical about the upper base , and the two isosceles trapezoids have the same upper base, the upper base b of the structure is 0.080mm long, the lower base a is 0.252mm long, and the height 0.5c of the trapezoid is 0.7165mm;

[0031] Step 2. Use SF 6 with O 2 The mixed gas is used to plasma etch the silicon thin film layer of the SOI substrate, the RIE power is 100W, and the etching time is 60s;

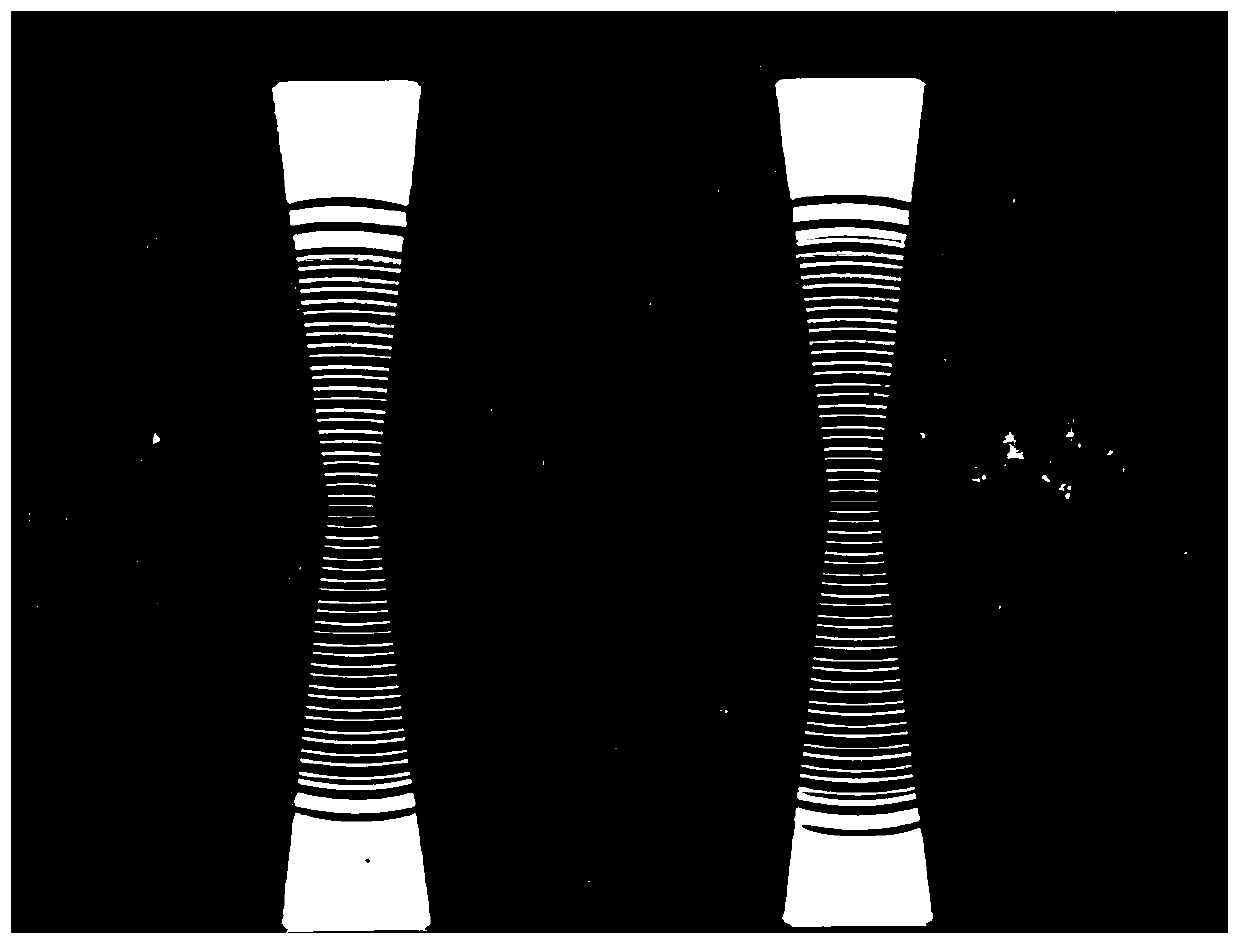

[0032] Step 3. Put the SOI substrate patterned in step 2 into an HF solution with a mass fraction of 40% for etching. After etching, the cured PDMS stamp is closely attached to the SOI substrate and the stamp is lifted, that is The top silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com