Preparation method of multifunctional integrated nano-wire array

A nanowire array, multi-functional technology, applied in the field of material preparation and functional modification, can solve the problems of high requirements for the selection of materials and complex process preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

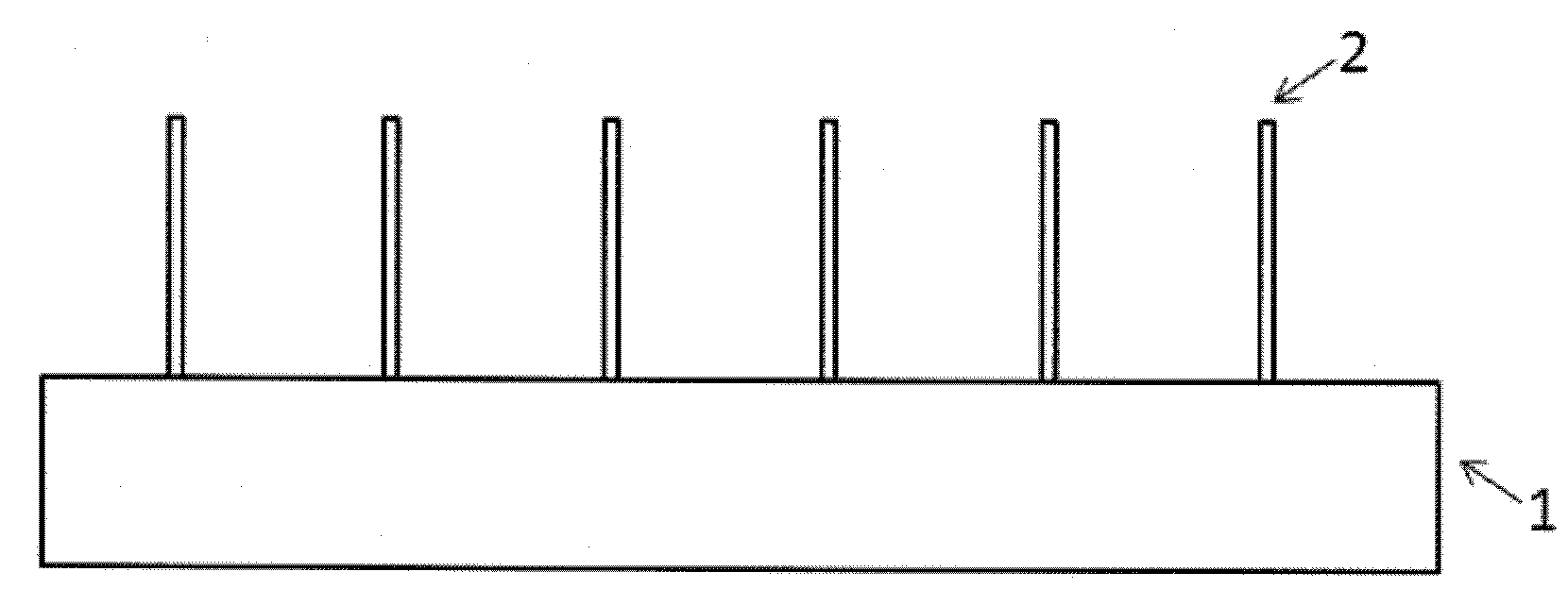

[0052] Example 1 This embodiment relates to the integration of semiconductor nanoparticles and nucleic acid molecules on the surface of Si nanowires. The process includes the following steps:

[0053] (1) The preparation of Si nanowires adopts the method of metal-assisted corrosion: the corrosion solution used contains 0.02 mol / L AgNO 3 and 5 mol / L HF solution, take an n-type (100) silicon chip with a diameter of 150 mm and put it in the etching solution, react at room temperature for 10 minutes, take it out, HNO 3 And after washing with deionized water, the Si nanowire array was obtained, and the length was 100 nm measured by scanning electron microscope;

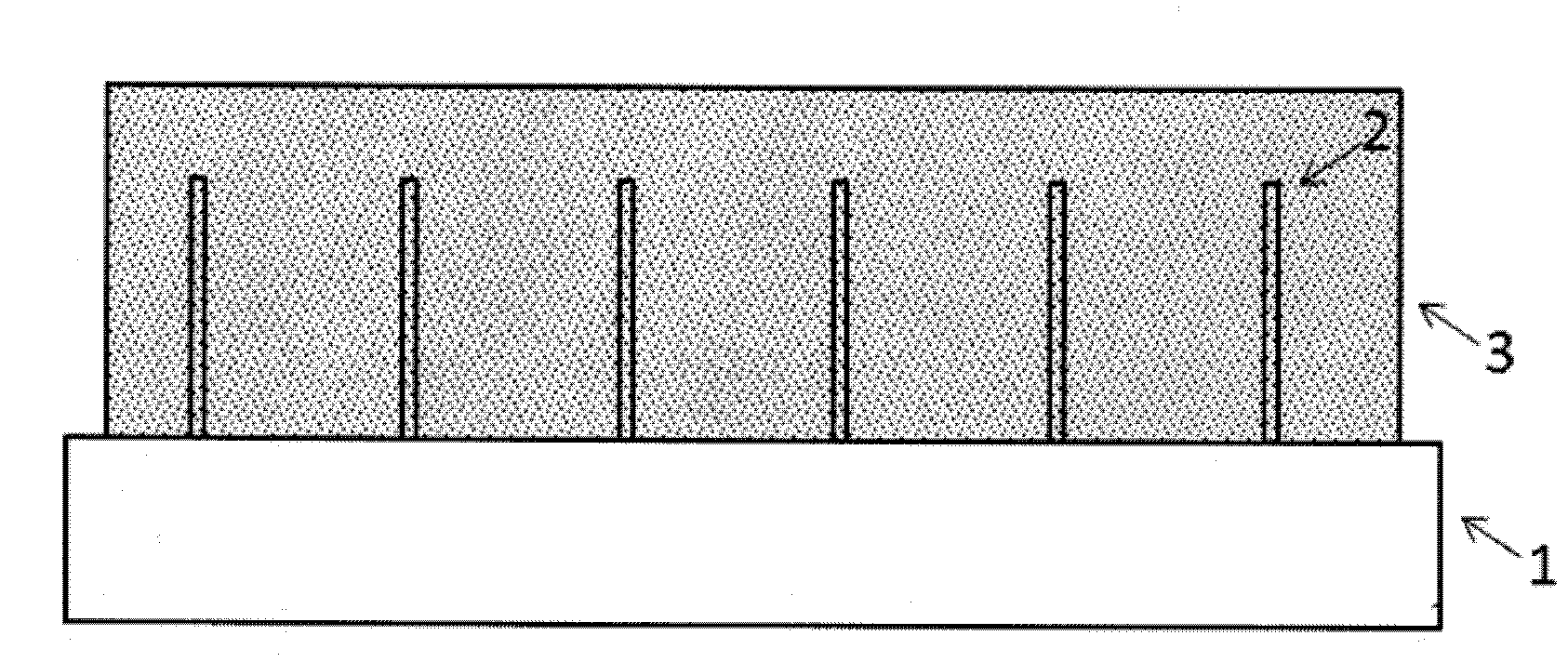

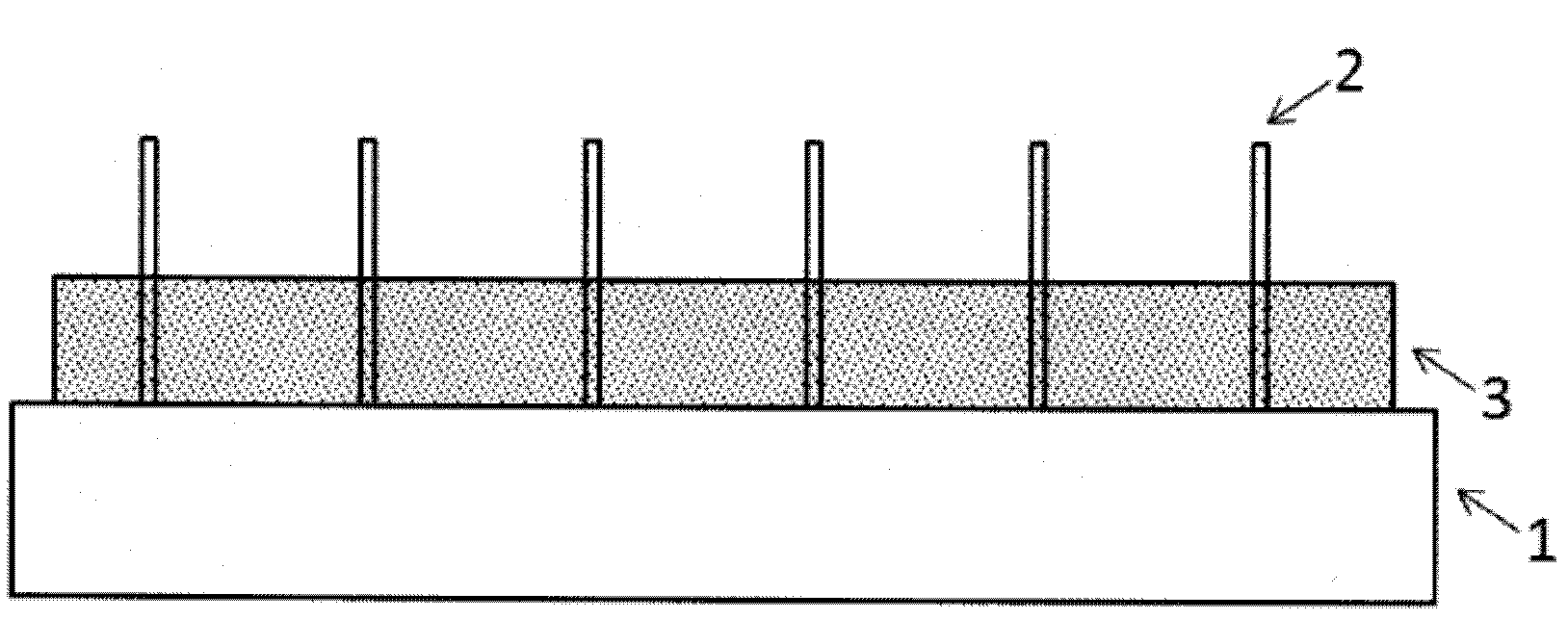

[0054] (2) Take 5 mL of PMMA with a viscosity of 1 mPa.s and drop it on the surface of the silicon wafer, place it in a vacuum desiccator, and extract the vacuum to 10 4 Pa, let it stand for 5min, so that the PMMA macromolecule evenly penetrates between the Si nanowires;

[0055] (3) Use a homogenizer in the air to pe...

Embodiment 2

[0059] Example 2 This embodiment relates to the integration of magnetic nanoparticles and proteins on the surface of the ZnO nanowire array, and the process includes the following steps:

[0060] (1) The preparation of ZnO nanowires adopts the CVD method: first weigh ZnO and C powder according to the molar ratio of 1:1 and mix them well, put them into one end of the quartz tube as the reaction source material; The bottom is placed on the other end of the quartz tube, and the distance from the raw material is kept at 10 cm; then the quartz tube is pushed into a high-temperature tube furnace, and the temperature at the raw material end is controlled to be 950 ° C, 50 sccm O 2 and 50sccm Ar as the reaction gas and carrier gas respectively, and the ZnO nanowire array was obtained after 1 hour of reaction, and the length of the nanowires was 10 μm measured by a scanning electron microscope;

[0061] (2) Take 500 μL of polyimide (PI) with a viscosity of 10 mPa.s and drop it on the...

Embodiment 3

[0066] Example 3 This embodiment relates to the integration of metal nanoparticles and cells on the surface of the TiO2 nanowire array, and the process includes the following steps:

[0067] (1) TiO 2 The template method was used to prepare the nanowires: first, 10 mL of tetrabutyl titanate was added to 50 mL of absolute ethanol, stirred for 5 min in an ice bath, and then a mixed solution containing 1 mL of deionized water, 0.05 mL of hydrochloric acid and 30 mL of ethanol was slowly added to it. A porous alumina template with a diameter of 20 mm, an average pore diameter of 100 nm, and a height of 30 μm was placed in the above solution for 30 min, taken out and dried, and then calcined in a muffle furnace at 500 ° C for 4 hours to make TiO 2 The nanowires are crystallized; after calcination, the template is placed in hydrochloric acid to remove alumina to obtain a length of 30 μm TiO 2 nanowire arrays;

[0068] (2) Take 500μL with a viscosity of 10 7 The polyvinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com