Engraved holographic antifakery labels checked by take-off and their production

A holographic anti-counterfeiting and production process technology, applied in the field of anti-counterfeiting, can solve the problems of weakening anti-counterfeiting strength and a single anti-counterfeiting method, and achieve the effect of good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

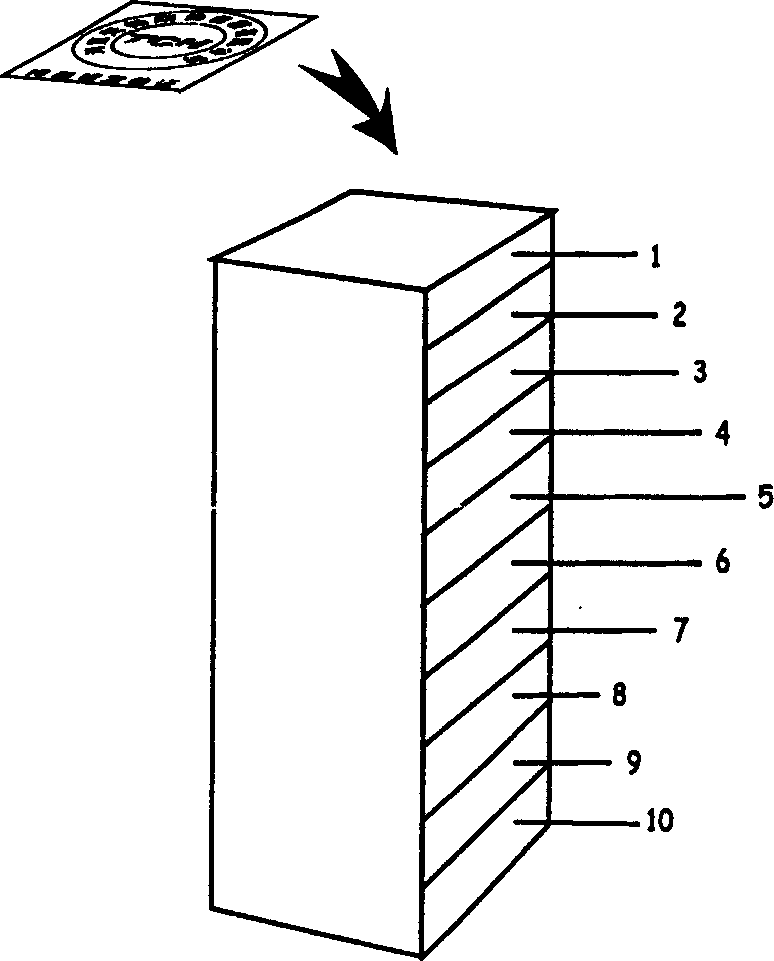

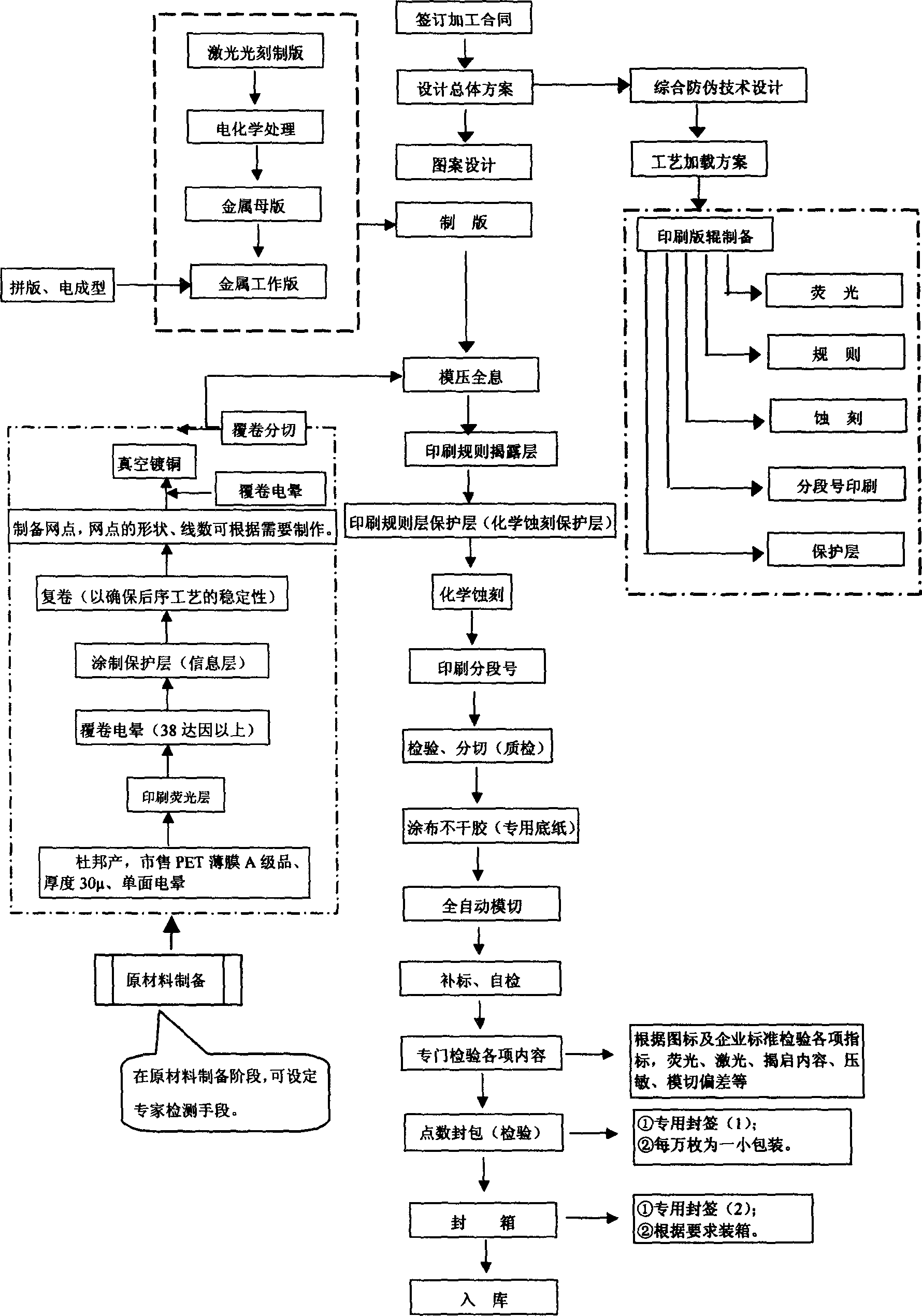

[0092] Such as figure 1 As shown, the present invention includes selecting a base film 2, a fluorescent layer 3 is arranged on the base film, a protective layer (information layer) 4 is arranged on the fluorescent layer, a special detection layer 5 is arranged on the protective layer, and a special detection layer is arranged on the special detection layer. A vacuum copper or aluminum layer 6 is arranged on the vacuum copper or aluminum layer, a laser holographic layer 7 is arranged on the vacuum copper or aluminum layer, a regular embossing layer 8 is arranged on the laser holographic layer, and a chemical etching pattern protection is arranged on the regular embossing layer. The coating layer 9 is provided with a special ink printing layer 1 on the other side of the base film, and a self-adhesive layer 10 is provided on the chemical etching layer.

[0093] The first layer: pressure-sensitive ink printing layer 1: special pressure-sensitive ink is printed on the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com