Flooring system including a dry glue

a technology of dry glue and floor, applied in the field of flooring systems, can solve problems such as additional steps, and achieve the effect of maximizing the effectiveness of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

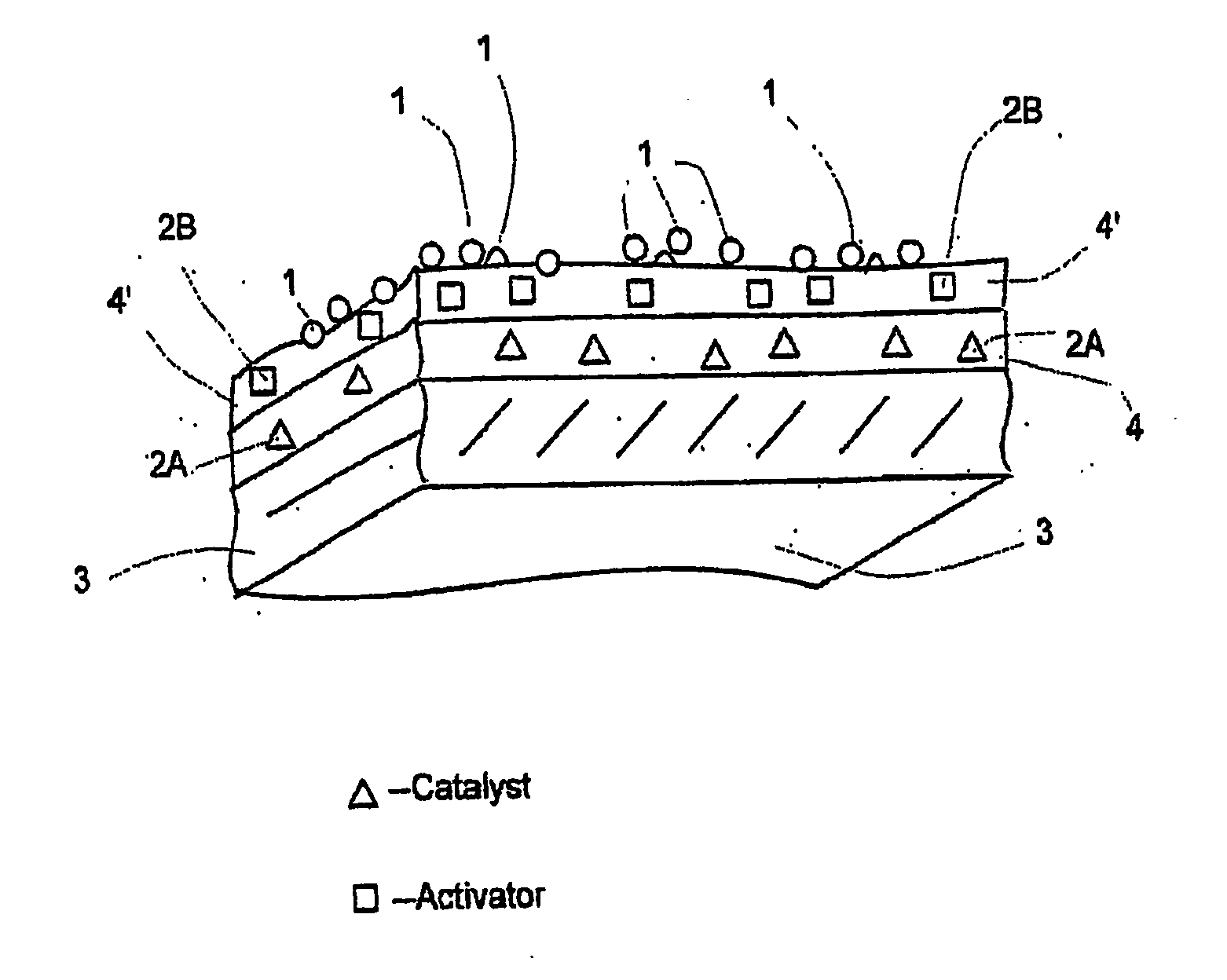

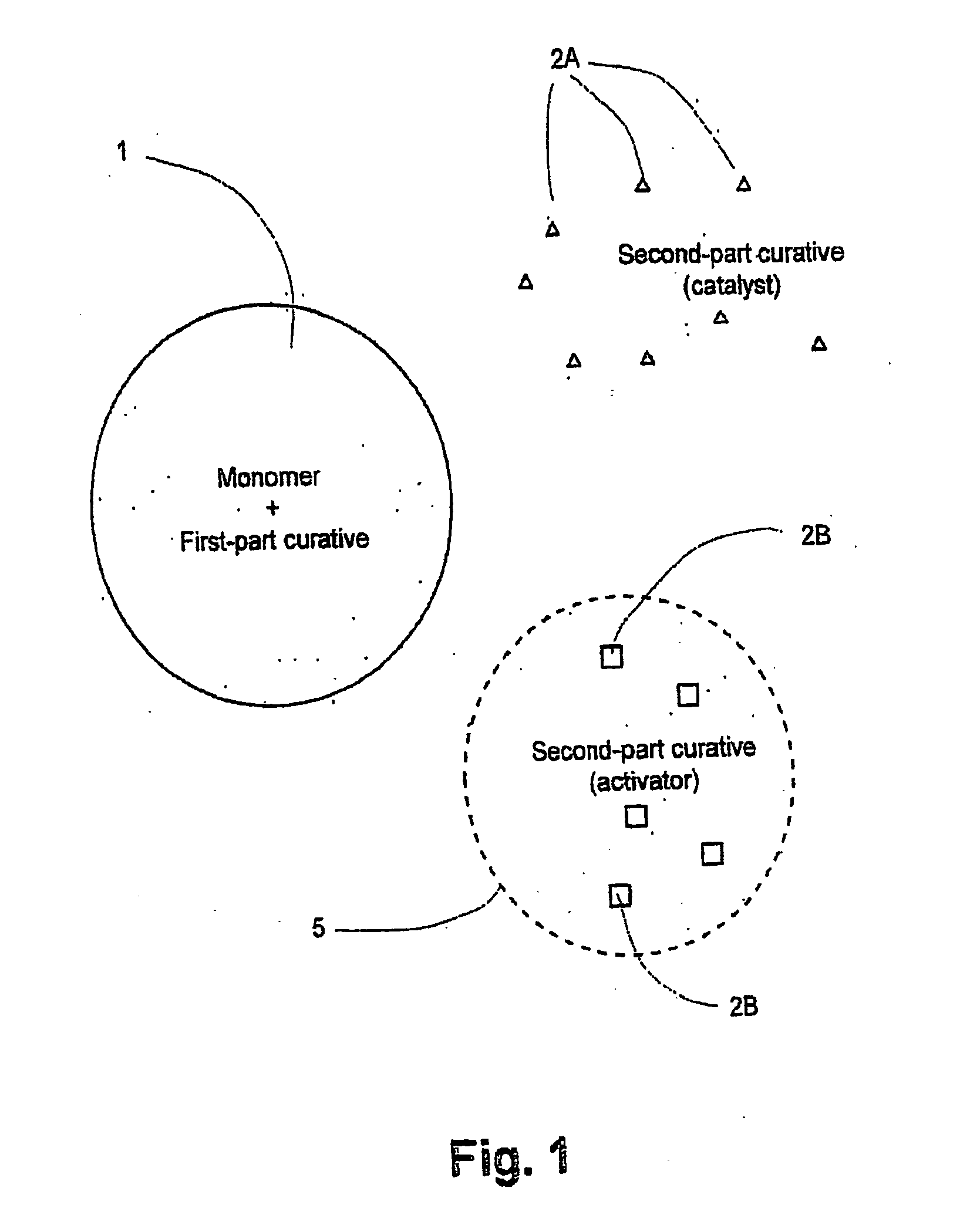

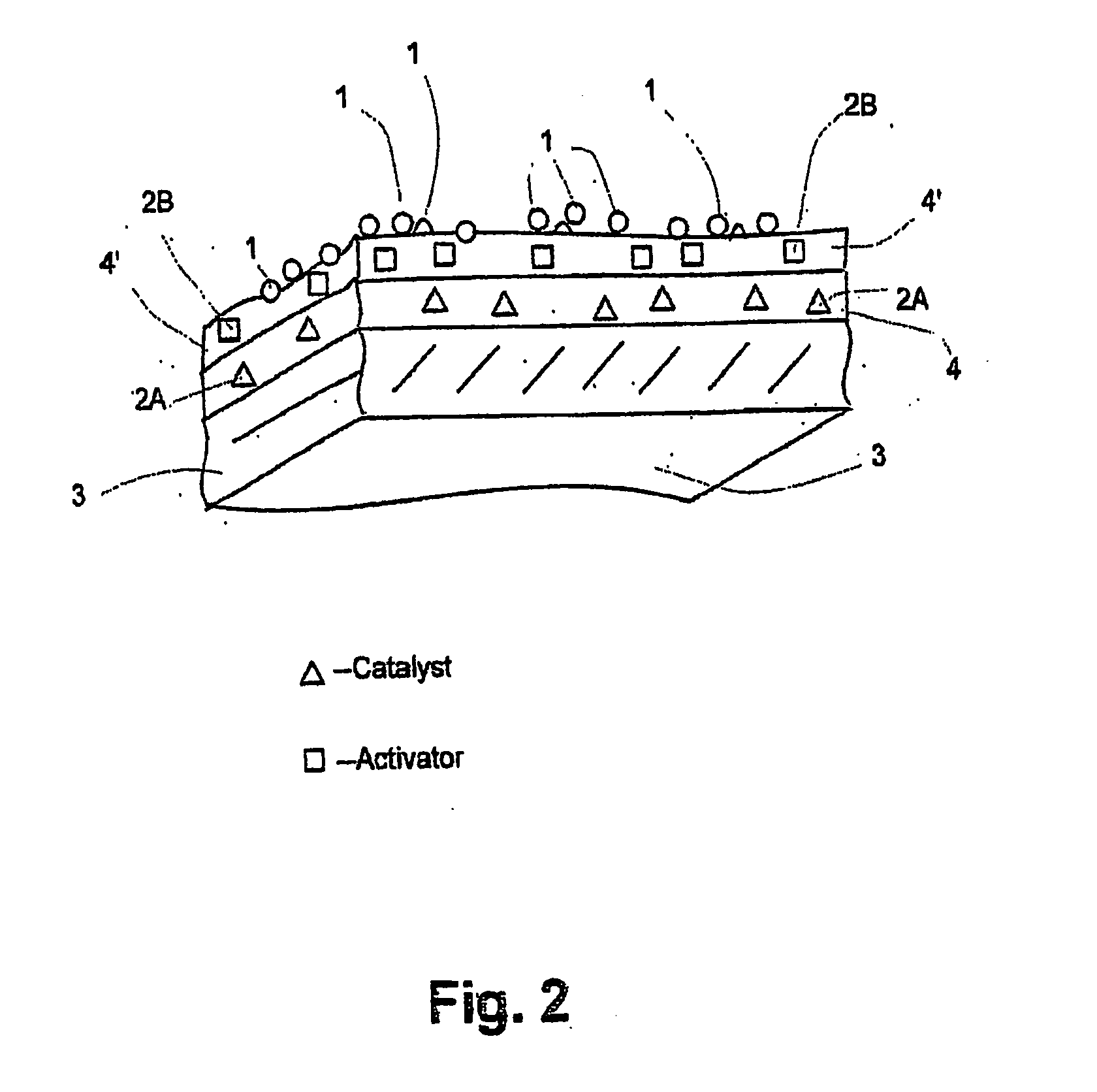

Method used

Image

Examples

example 1

Preparation of Microcapsules Containing 5% Initiator in Internal Phase

[0154]The composition of the capsules is as follows:

Internal Phase (IP)Hexanedioldimethacrylate,156.9gTetrahydrofurfuryl methacrylate,17.4gCumene hydroperoxide (CHP)9.2g1st Water Phase:Deionized water,112gAcrylic acid butyl acrylate copolymer,17.5g5% NaOH aqueous solution14.1gmethoxymethyl methylol melamine2.9g2nd Water PhaseDeionized water33.0gPolyacrylic acid6.1gMethoxymethyl methylol melamine17.4g

[0155]A procedure for preparing microcapsules is as follows. The 1st Water Phase was prepared according to the composition as listed above, and pH of the aqueous solution was adjusted to 5.82 with 5% sodium hydroxide solution, and maintaining the temperature of the solution at 65° C. Then the premixed internal phase was pre-heated to 65° C. was pre-emulsified into the 1st Water Phase by high shear agitation at 800 rpm to form an emulsion and then milled at 1700 rpm with a high shear milling blade until an emulsion drop...

example

Preparation of Microcapsules Containing 2.5% Initiator in Internal Phase

[0156]The composition of and the procedures for preparing the microcapsules are the same as in Example 1 except for the following:

Internal Phase (IP)Hexanedioldimethacrylate,161.0 g Tetrahydrofurfuryl methacrylate,17.9 gCumene hydroperoxide (CHP)4.58 g

example 3

Preparation of Microcapsules Containing 1.5% Initiator in Internal Phase

[0157]The composition of and the procedures for preparing the microcapsules are the same as in Example 1 except for the following:

Internal Phase (IP)Hexanedioldimethacrylate,162.6 g Tetrahydrofurfuryl methacrylate,18.1 gCumene hydroperoxide (CHP)2.75 g

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com