Method for preparing porous carbon born nano ferrite wave-absorbing material

A nano-ferrite and wave-absorbing material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy agglomeration of nano-ferrite, achieve easy parameter control, easy industrialization, and prevent crystal growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

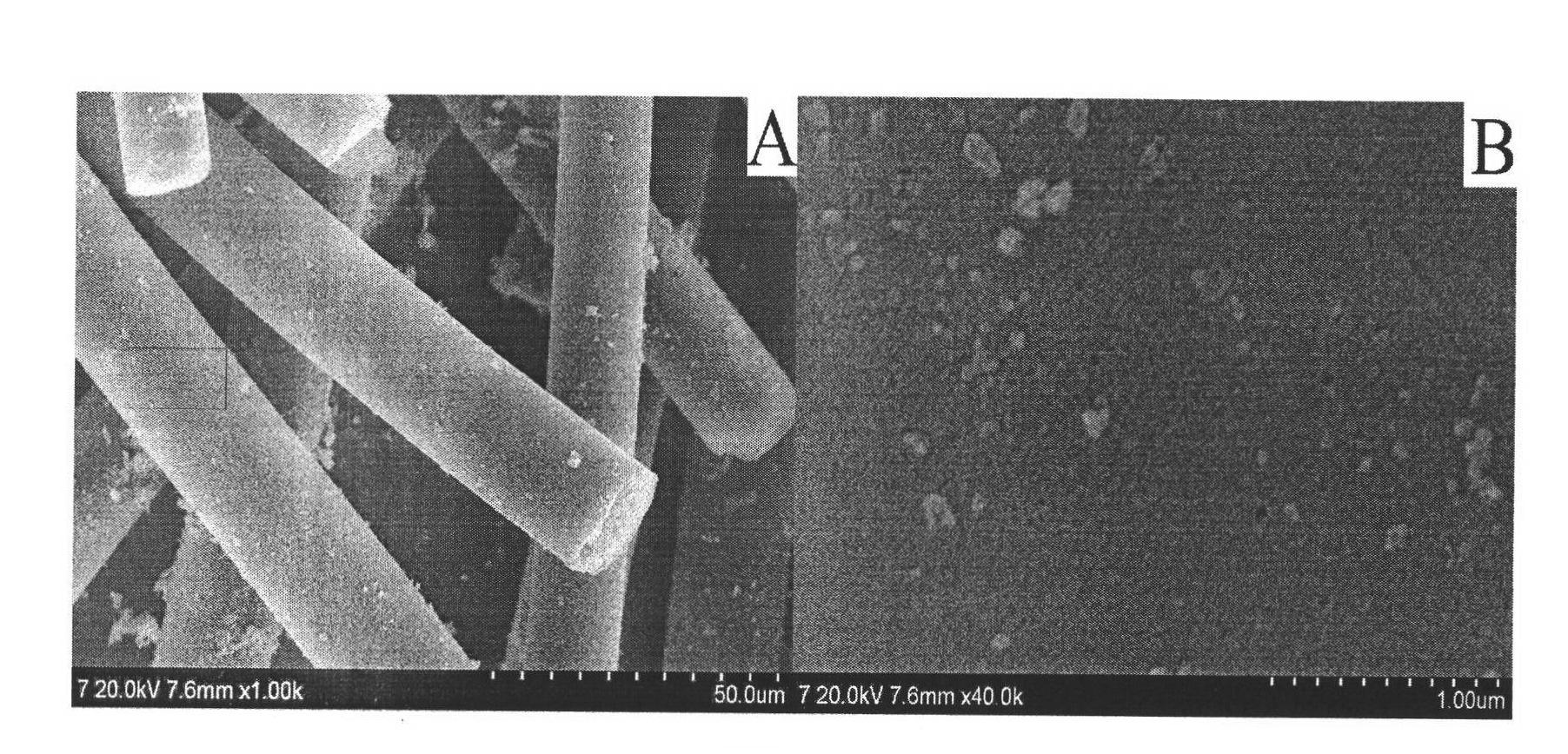

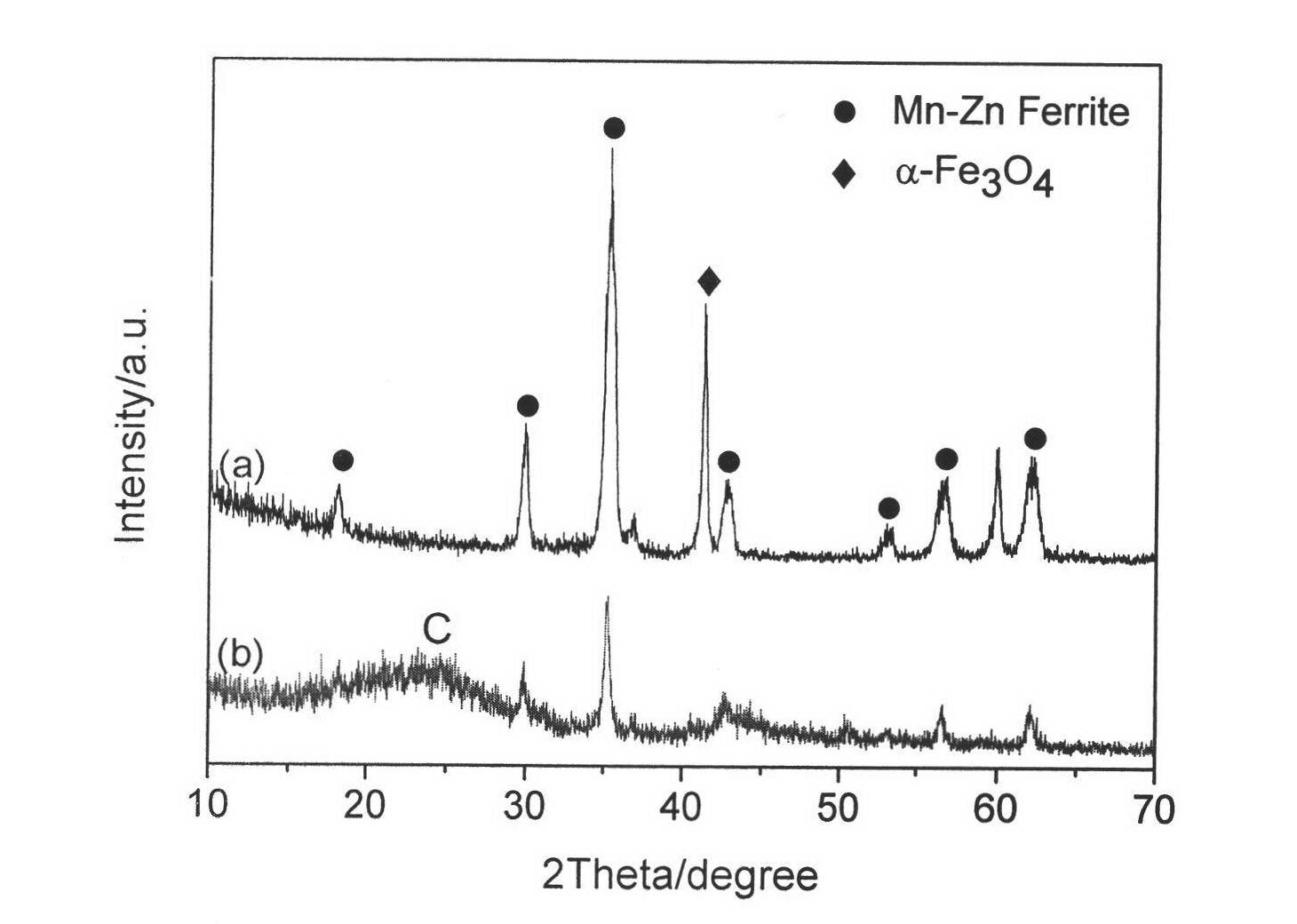

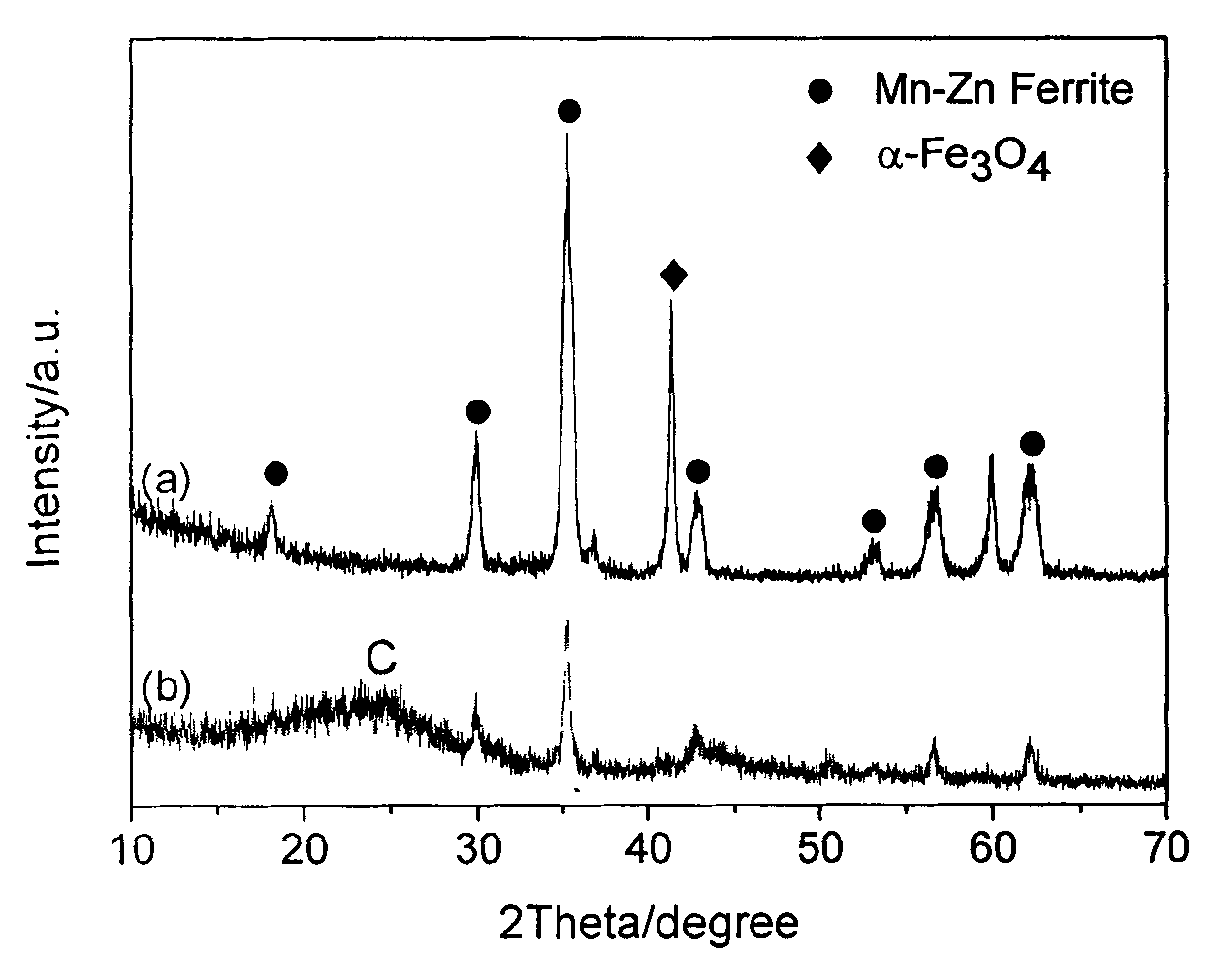

[0022] The preparation method of a novel porous carbon material loaded nano-ferrite absorbing material is according to (molar ratio Zn(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 9H 2 O:MnCl 2 4H 2 O=0.2: 2: 0.8) take medicine, be mixed with solution and stir with magnetic stirrer; With the ratio of the amount of metal ion and citric acid substance 1: 1, weigh citric acid, be dissolved in deionized water, use drop Slowly add the solution dropwise into the above solution, and stir while adding dropwise. After stirring evenly, adjust the pH value of the solution to pH=4 with ammonia water; stir the above solution at a constant temperature of 80°C for 2 hours; : 0.5 Weigh the activated carbon fiber and add it, continue to heat and stir until a viscous activated carbon fiber / gel mixture is formed; put it into an oven at 130°C for drying.

[0023] Put the active carbon fiber / gel dry glue mixture into the porcelain boat, then put the porcelain boat into the center of the quartz tube in the ...

Embodiment 2

[0025] The preparation method of a novel porous carbon material loaded nano-ferrite absorbing material is according to (molar ratio Zn(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 9H 2 O:MnCl 2 4H 2 O=0.2: 2: 0.8) take medicine, be mixed with solution and stir with magnetic stirrer; With the ratio of the amount of metal ion and citric acid substance 1: 1, weigh citric acid, be dissolved in deionized water, use drop Slowly add the solution dropwise into the above solution, and stir while adding dropwise. After stirring evenly, adjust the pH value of the solution to pH=4 with ammonia water; stir the above solution at a constant temperature of 80°C for 2 hours; : 2 Weigh the activated carbon fiber and add it, continue to heat and stir until a viscous activated carbon fiber / gel mixture is formed; put it into an oven at 130° C. for drying.

[0026] Put the active carbon fiber / gel dry glue mixture into the porcelain boat, then put the porcelain boat into the center of the quartz tube in the ...

Embodiment 3

[0028] The preparation method of a novel porous carbon material-loaded nano-ferrite absorbing material is according to a certain stoichiometric ratio (molar ratio Zn(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 9H 2 O:MnCl 2 4H 2 O=0.2: 2: 0.8) take medicine, be mixed with solution and stir with magnetic stirrer; With the ratio of the amount of metal ion and citric acid substance 1: 1, weigh citric acid, be dissolved in deionized water, use drop Slowly add the solution dropwise into the above solution, and stir while adding dropwise. After stirring evenly, adjust the pH value of the solution to pH=4 with ammonia water; stir the above solution at a constant temperature of 80°C for 2 hours; : 0.5 Weigh activated carbon and add it, continue to heat and stir until a thick activated carbon / gel mixture is formed; put it into an oven at 130° C. to dry to obtain an activated carbon / gel xerogel mixture.

[0029] Put the activated carbon / gel dry glue mixture into the porcelain boat, then put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com