A kind of defoamer for printed circuit board cleaning

A technology for printed circuit boards and defoamers, which is applied in the direction of foam dispersion/prevention, and can solve problems such as transparency effects, solubility aiding foam, and reduction of copolymer solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

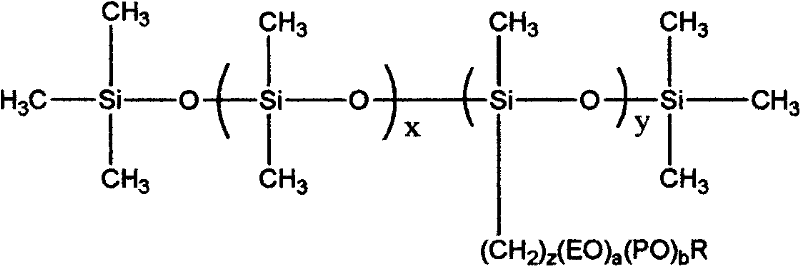

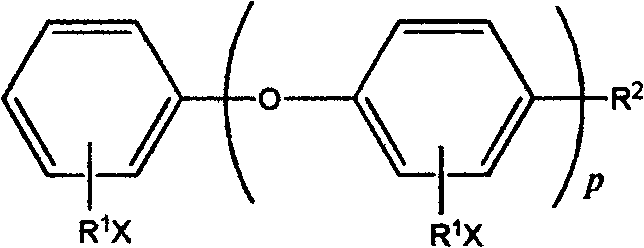

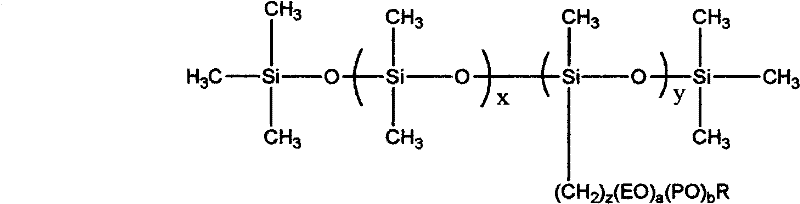

Image

Examples

Embodiment 1

[0035] At room temperature, the silicon polyether A1 was mixed with diethylene glycol butyl ether and deionized water in a ratio of 5:8:87.

Embodiment 2

[0037] At room temperature, the silicon polyether A2 was mixed with ethylene glycol hexyl ether, deionized water, and sodium dodecylbenzenesulfonate in a ratio of 8:13:78:1.

Embodiment 3

[0039] At room temperature, the silicon polyether A3 was mixed with ethylene glycol butyl ether, deionized water, and sodium tetradecyl diphenyl ether disulfonate in a ratio of 6:10:81:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com