Organic silicon-modified polyether ester emulsion defoamer and preparation method thereof

A polyether ester and silicone technology, applied in the field of non-ionic surfactant preparation, can solve problems such as product residue, environmental pollution, and impact on workers' health, and achieve excellent anti-foaming performance, good dispersibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

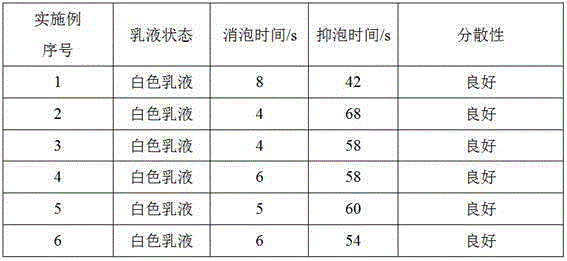

Examples

Embodiment 1

[0028] (1) Add 500g of hydrogen-containing silicone oil with a molar ratio of 1:10 and a hydrogen content of 1.0%, self-made polyoxypropylene polyoxyethylene pentaerythritol ether stearate, and 2g of trifluoroacetic acid to a mixer equipped with a thermometer and agitator. In a four-neck flask with a nitrogen gas guide tube and a condenser, start the stirrer, raise the temperature to 100° C. under a nitrogen atmosphere and keep the temperature for 10 hours. After the reaction, cool to obtain a silicone-modified polyether ester.

[0029] (2) Add 14g of Viscoatex46 into 521.5mL of water, stir for 5 minutes until uniform, adjust the pH to 8 with 10% NaOH solution, and set aside.

[0030] (3) Add 140 g of the silicone-modified polyether ester prepared in step (1), and 24.5 g of Span-80 and Tween-80 composite emulsifiers with an HLB value of 8 into a round-bottomed flask equipped with stirring, and heat to 70°C , after stirring evenly at high speed, stop heating, then quickly add 2...

Embodiment 2

[0032] (1) Add 500g of hydrogen-containing silicone oil with a hydrogen content of 1.0% in a molar ratio of 1:15, self-made polyoxypropylene polyoxyethylene pentaerythritol ether stearate and 1g of trifluoroacetic acid in a mass fraction to a thermometer equipped with , a stirrer, a nitrogen air pipe and a four-necked flask with a condenser, start the stirrer, raise the temperature to 110° C. under a nitrogen atmosphere and keep it warm for 8 hours. After the reaction, cool to obtain a silicone-modified polyether ester.

[0033] (2) Add 7g of Viscoatex46 into 453mL of water, stir for 3 minutes until uniform, adjust the pH to 7 with 10% NaOH solution, and set aside.

[0034] (3) Add 210g of the silicone-modified polyetherester prepared in step (1) and 30g of Span-80 and Tween-80 composite emulsifiers with an HLB value of 9.5 into a round-bottomed flask equipped with stirring, and heat to 60°C. After stirring evenly at a high speed, stop heating, then quickly add 200g of thicken...

Embodiment 3

[0036] (1) Add 500g of hydrogen-containing silicone oil with a hydrogen content of 1.2% in a molar ratio of 1:10, self-made polyoxypropylene polyoxyethylene pentaerythritol ether stearate, and a mass fraction of 2g of trifluoroacetic acid to a thermometer equipped with , a stirrer, a nitrogen air pipe and a four-necked flask with a condenser, start the stirrer, raise the temperature to 110° C. under a nitrogen atmosphere and keep it warm for 8 hours. After the reaction, cool to obtain a silicone-modified polyether ester.

[0037] (2) Add 14g of sodium carboxymethylcellulose into 446mL of water, stir for 3 minutes until uniform, adjust the pH to 7 with 10% NaOH solution, and set aside.

[0038] (3) Add 210 g of silicone-modified polyether ester prepared in step (1), and 30 g of Span-80, Tween-80, and AEO-3 composite emulsifiers with an HLB value of 8.5 into a round-bottomed flask equipped with stirring, and heat After stirring at a high speed to 60°C, stop heating, then quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com