Low-viscosity optical adhesive composition, a preparation method thereof and application thereof to perfusion of touch screen to realize full lamination

An optical adhesive and composition technology, applied in the directions of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of poor flatness, low level, easy bubble production efficiency, etc., and achieve good light transmission. high rate, low refractive index, good wetting and debubbling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention and its beneficial effects will be described in further detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

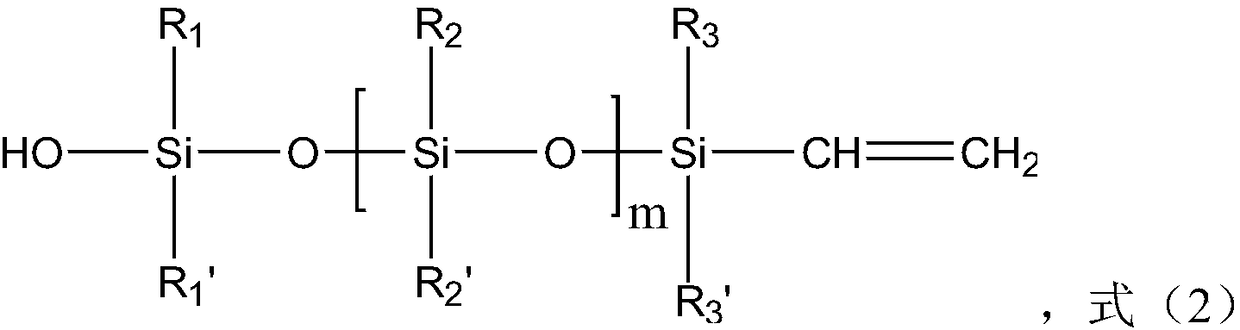

[0036] A is vinyl silicone oil, A-1 is vinyl-terminated polydimethylsiloxane, the viscosity is 50 mPa·s, and the vinyl content is 1.5%; A-2 is vinyl-terminated polymethylvinylsiloxane, The viscosity is 200mPa·s, and the vinyl content is 0.8%; A-3 is ordinary vinyl silicone oil (the vinyl is not at the end), the viscosity is 50 mPa·s, and the vinyl content is 1.5%; A-4 is ordinary of vinyl silicone oil (the vinyl is not at the end), the viscosity is 200 mPa·s, and the vinyl content is 0.8%.

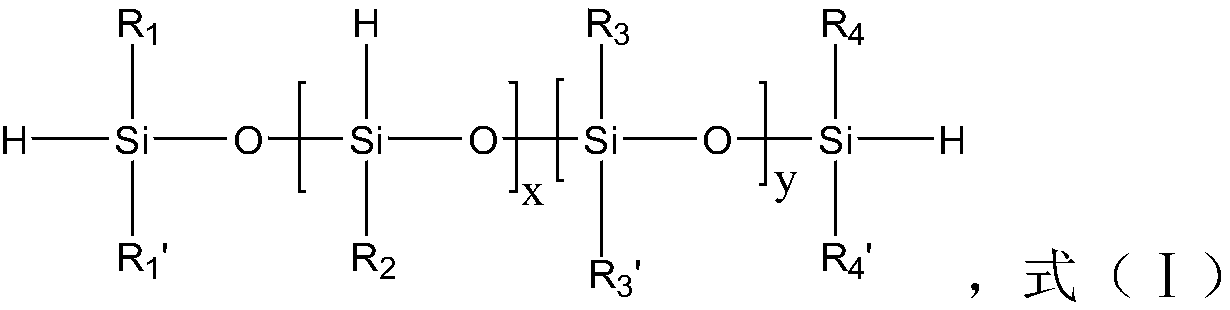

[0037] B is a hydrogen-containing polysiloxane, B-1 is a hydrogen-containing polysiloxane in which the terminal hydrogen and side chain partial hydrogen coexist, the viscosity is 5mPa·s, and the hydrogen content is 0.3%; B-2 is the terminal Hydrogen-containing polysiloxane coexisting with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com