Antifoaming agent for metal processing cutting fluid

A metal processing and cutting fluid technology, applied in the field of fine chemical preparations, can solve problems such as poor compatibility, poor anti-foaming performance, and poor anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of fatty alcohol polyethers:

[0031] Prepare fatty alcohol polyethers L1, L2 and L3, the general formula of fatty alcohol polyethers is RO(EO) m (PO) n The values of H, R, m and n are shown in Table 1:

[0032] Table 1 Fatty alcohol polyethers L1, L2, and L3

[0033] Fatty alcohol polyether

L1

L2

L3

R

n-octyl

n-hexadecyl

n-Docosyl

m

2

35

50

n

10

22

55

[0034] Preparation of silicon polyether:

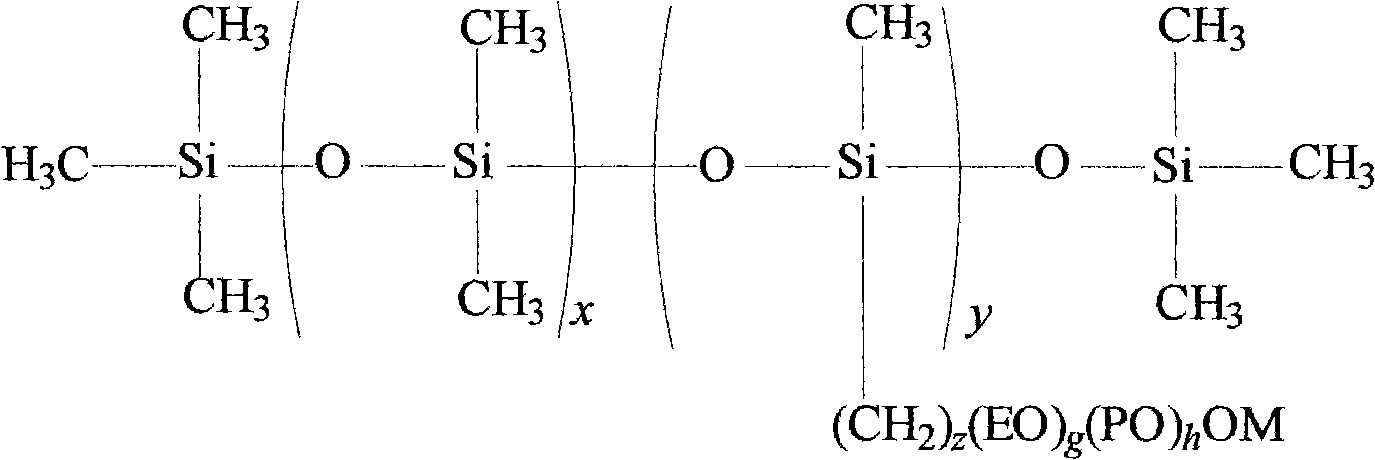

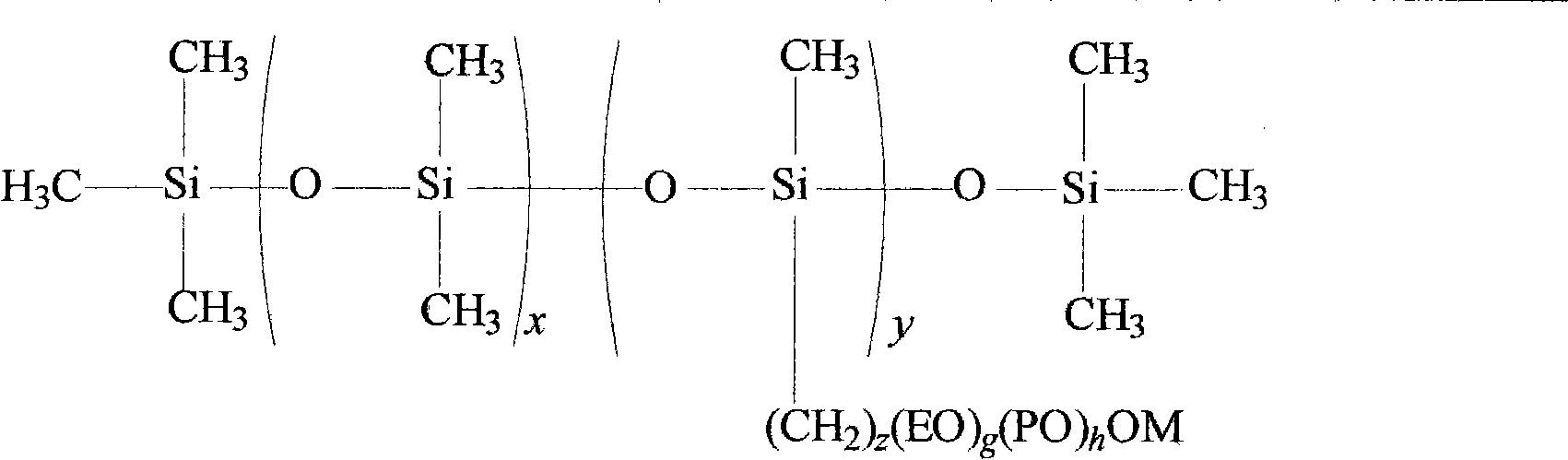

[0035] Prepare silicon polyether O1, O2 and O3, the structural formula of silicon polyether is:

[0036]

[0037] The silicon polyethers O1, O2 and O3 used by the different defoamers prepared by this patent method, the values of M, x, y, z, g and h are shown in Table 2:

[0038] Table 2 Silicon polyether O1, O2 and O3

[0039] Silicon polyether

O1

O2

O3

M

-H

-CH 3

-CH 2 CH 3

x

15

160

...

Embodiment

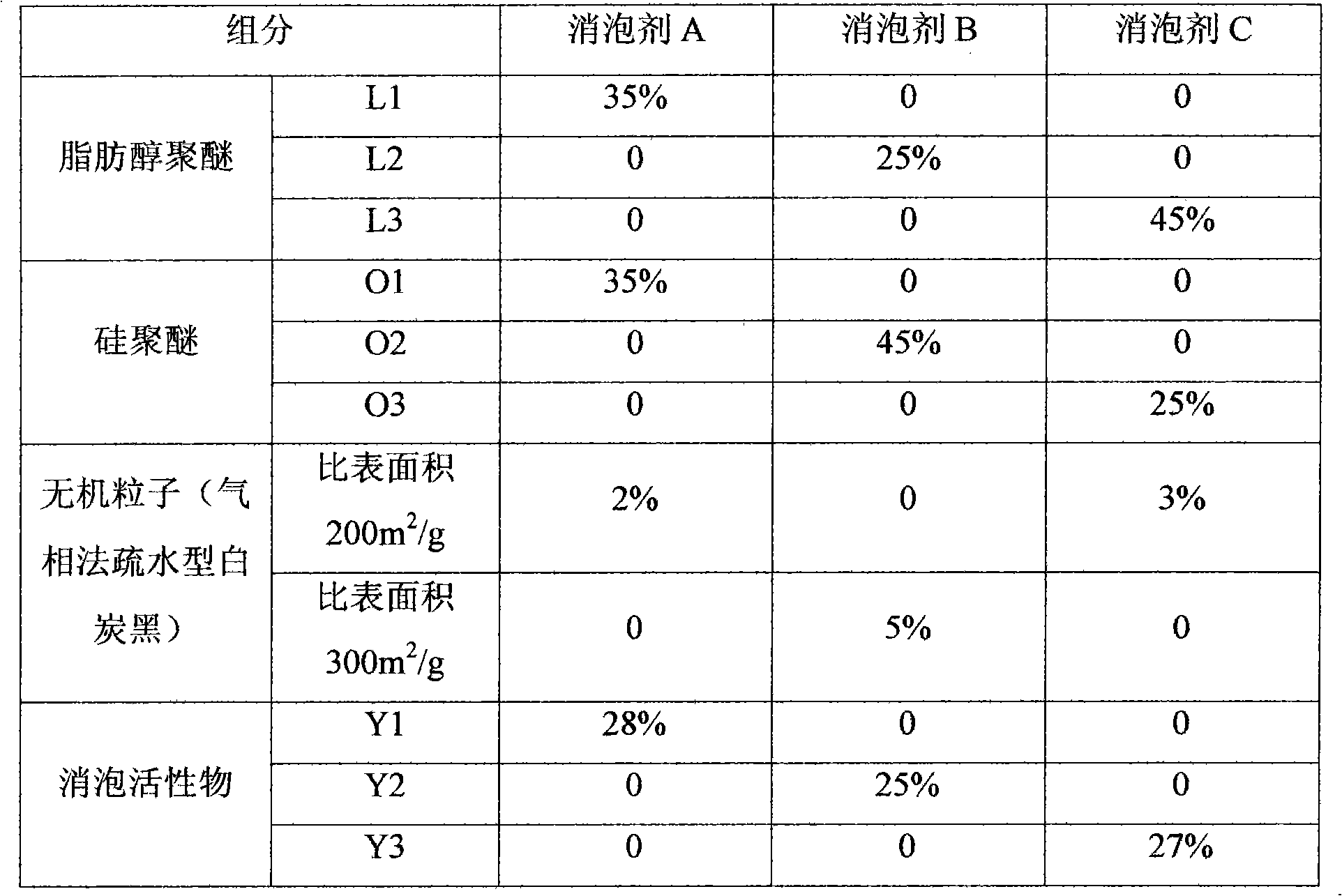

[0044] Preparation of patented defoamer:

[0045] Prepare defoamers A, B and C according to the preparation process of the patented defoamer mentioned above and the formula in Table 3. The content of each component in the formula is the content of mass percentage.

[0046] Defoaming active substance Y1 in table 3 is the defoamer described in Example 2 in CN1613537; Defoaming active substance Y2 is the defoamer described in Example 1 in CN1641097; Defoaming active substance Y3 is the defoamer described in Example 3 in CN1919936 .

[0047] Table 3 Formula of patented defoamer

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com