Organic silicon defoaming composition

A composition and silicone technology, applied in the direction of foam dispersion/prevention, can solve the problems of easy gelation of reactants, unstable storage of active substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

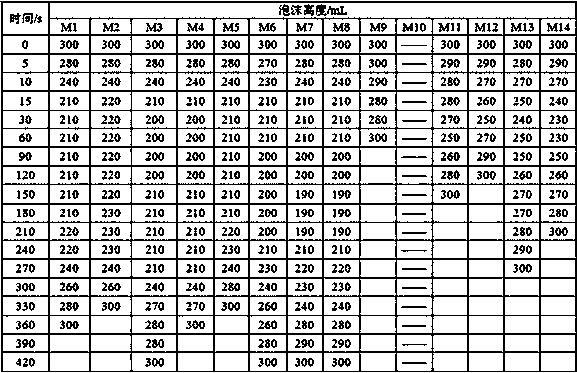

Examples

Embodiment 1

[0034] Add 50 parts into the reaction vessel, the viscosity is 50mPa.s (unless otherwise specified, the viscosity mentioned below is the kinematic viscosity value at 25°C), and the structural formula is (Me) 3 SiO (MeViSiO) 2 [(Me) 2 SiO] 50 Si(Me) 3 (It is mentioned in the text that Vi is the abbreviation of vinyl functional group) vinyl polyorganosiloxane, 25 parts of hydrogen-containing silicone resin with a hydrogen content of 0.1%, mix well and heat up to 70°C, add 0.0005 Parts (calculated as platinum) chloroplatinic acid isopropanol solution, continue to heat up to 100 ° C for 1 h; then add 400 parts dropwise to the container 3 SiO(MeHSiO) 20 [(Me) 2 SiO] 350 Si(Me) 3 Hydrogen-containing polyorganosiloxane, the dropping time is controlled to be 2h, and the reaction is continued at 100°C for 1h after the dropping is completed; 15 parts of hydrophobic precipitation silica Sipernat® D10 (sold by DegussaGmbh), 10 parts of methyl MQ silicone resin (M:Q ratio 0.4:1), s...

Embodiment 2

[0036] Add 400 parts in the reaction vessel, the viscosity is 100000mPa. 3 SiO (MeViSiO) 200 [(Me) 2 SiO] 1500 Si(Me) 3 Vinyl polyorganosiloxane, 10 parts of hydrogen-containing silicone resin with a hydrogen content of 0.01%, fully mixed and heated to 70 ° C, adding 0.05 parts (calculated as platinum) isopropanol solution of chloroplatinic acid , continue to heat up to 100°C for 0.5h; then dropwise add 50 parts of 3 SiO(MeHSiO) 2 [(Me) 2 SiO] 10 Si(Me) 3 Hydrogen-containing polyorganosiloxane, control the dropping time for 1h, and continue to react at 100°C for 1h after the dropping is completed; add 20 parts of hydrophobic precipitation silica Sipernat® D13 (sold by DegussaGmbh), 20 parts of methyl MQ silicone resin (M:Q ratio 0.8:1), stirred at 100°C for 1 hour, and cooled down to room temperature to obtain defoaming composition S2.

Embodiment 3

[0038] Add 200 parts of the viscosity is 50mPa.s, structural formula is (Me) in the reaction vessel 3 SiO (MeViSiO) 2 [(Me) 2 SiO] 50 Si(Me) 3 Vinyl polyorganosiloxane, 10 parts of hydrogen-containing silicone resin with a hydrogen content of 0.2%, fully mixed and heated to 70 ° C, adding 0.05 parts (calculated as platinum) isopropanol solution of chloroplatinic acid , continue to heat up to 100°C for 1 hour; then dropwise add 140 parts of 3 SiO(MeHSiO) 2 [(Me) 2 SiO] 55 Si(Me) 3 Hydrogen-containing polyorganosiloxane, the dropping time is controlled to be 2h, and the reaction is continued at 150°C for 1h after the dropping is completed; 75 parts of hydrophobic precipitation silica Sipernat® D17 (sold by DegussaGmbh), 75 parts of methyl MQ silicone resin (M:Q ratio 0.9:1), stirred at 150°C for 2h, cooled to room temperature to obtain defoaming composition S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com