Photo-thermal dual-cured organosilicon LOCA (liquid optical clear adhesive) composition

A dual-curing, silicone technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of non-curing in dark areas, large shrinkage, poor reliability, etc., and achieve easy rework and defoaming Good, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

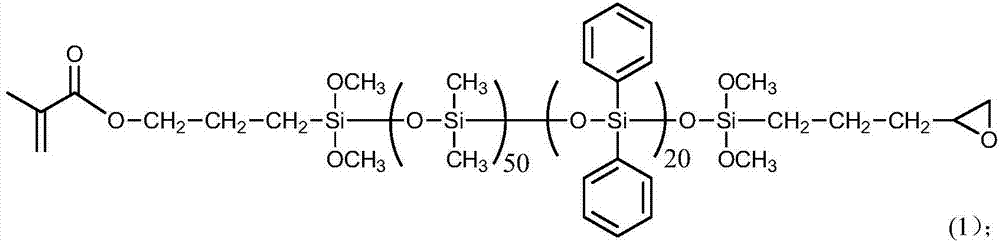

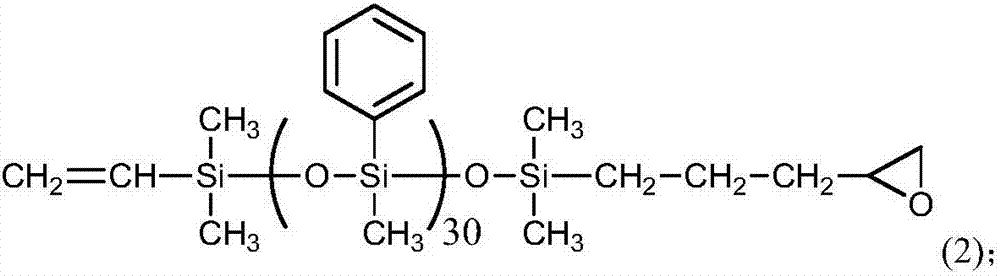

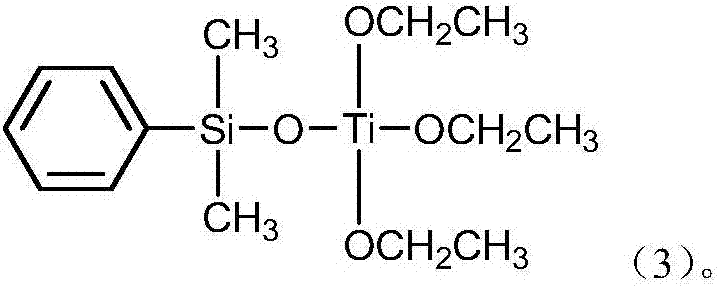

[0078] Weigh 50 parts of component A1 vinyl phenyl silicone oil, 10 parts of component B1 vinyl phenyl silicone resin, 2 parts of component C1 terminal hydrogen-containing phenyl crosslinking agent, component D side chain hydrogen-containing phenyl Add 7 parts of joint agent, 0.1 part of component E inhibitor, 1 part of component H1 tackifier, and 0.01 part of component I flame retardant into the mixer in turn, stir for 2 hours, then add 0.1 part of component F platinum catalyst, Divide 0.1 parts by weight of photoinitiated platinum catalyst into G, stir for 10 minutes, vacuum defoam for 5 minutes, and pass through 3000mJ / cm 2 After high-energy ultraviolet light curing, heat at 60°C for 10 minutes to completely cure, and the penetration of the obtained colloid is 75.

Embodiment 2

[0080] Weigh 70 parts of component A2 vinyl phenyl silicone oil, 4 parts of component B2 vinyl phenyl silicone resin, 5.5 parts of component C1 terminal hydrogen-containing phenyl cross-linking agent, component D side chain hydrogen-containing phenyl cross-linking agent Add 2.7 parts of joint agent, 0.1 part of component E inhibitor, 1 part of component H2 tackifier, and 0.01 part of component I flame retardant into the mixer in turn, stir for 2 hours, then add 0.1 part of component F platinum catalyst, Divide 0.1 parts by weight of photoinitiated platinum catalyst into G, stir for 10 minutes, vacuum defoam for 5 minutes, and pass through 3000mJ / cm 2 After high-energy ultraviolet light curing, heat at 60°C for 10 minutes to completely cure, and the penetration of the obtained colloid is 90.

Embodiment 3

[0082] Weigh 65 parts of component A1 vinylphenyl silicone oil, 4 parts of component B1 vinylphenyl silicone resin, 3.2 parts of component C2 terminal hydrogen-containing phenyl crosslinking agent, component D side chain hydrogen-containing phenyl crosslinking agent Add 2.9 parts of joint agent, 0.1 part of component E inhibitor, 1 part of component H3 tackifier, and 0.05 part of component I flame retardant into the mixer in turn, stir for 2 hours, then add 0.1 part of component F platinum catalyst, Divide 0.1 parts by weight of photoinitiated platinum catalyst into G, stir for 10 minutes, vacuum defoam for 5 minutes, and pass through 3000mJ / cm 2 After high-energy ultraviolet light curing, heat at 60°C for 10 minutes to completely cure, and the colloid with a penetration of 98 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com