Method for mechanically dispersing high-viscosity organic silicon composition

A technology of mechanical dispersion and high viscosity, applied in the field of silicone emulsion preparation, can solve the problems of difficulty in controlling the degree of crosslinking of silicone polyether, high cost, and difficulty in controlling emulsion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

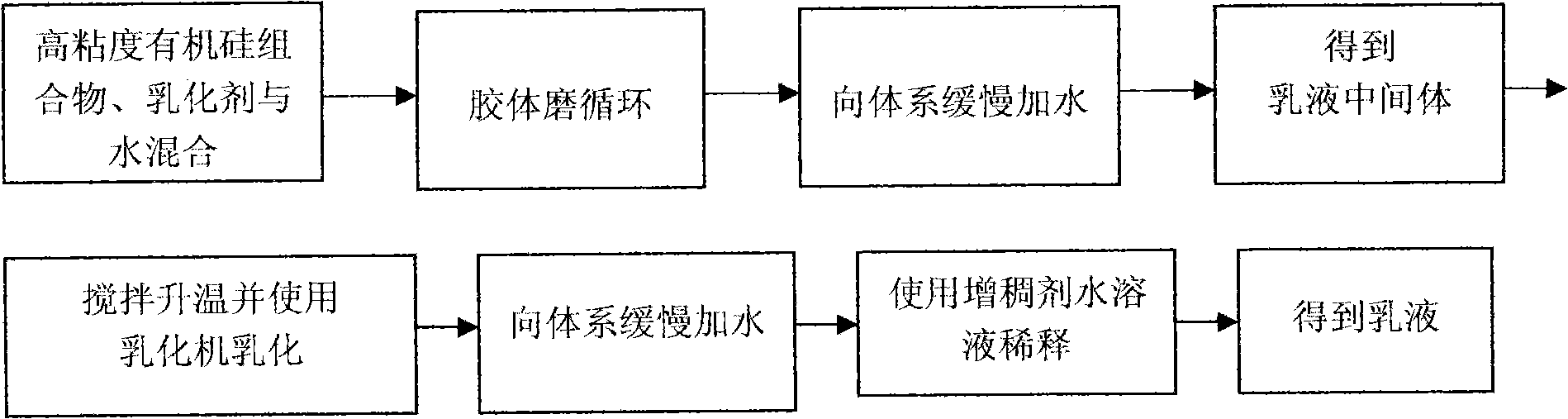

Method used

Image

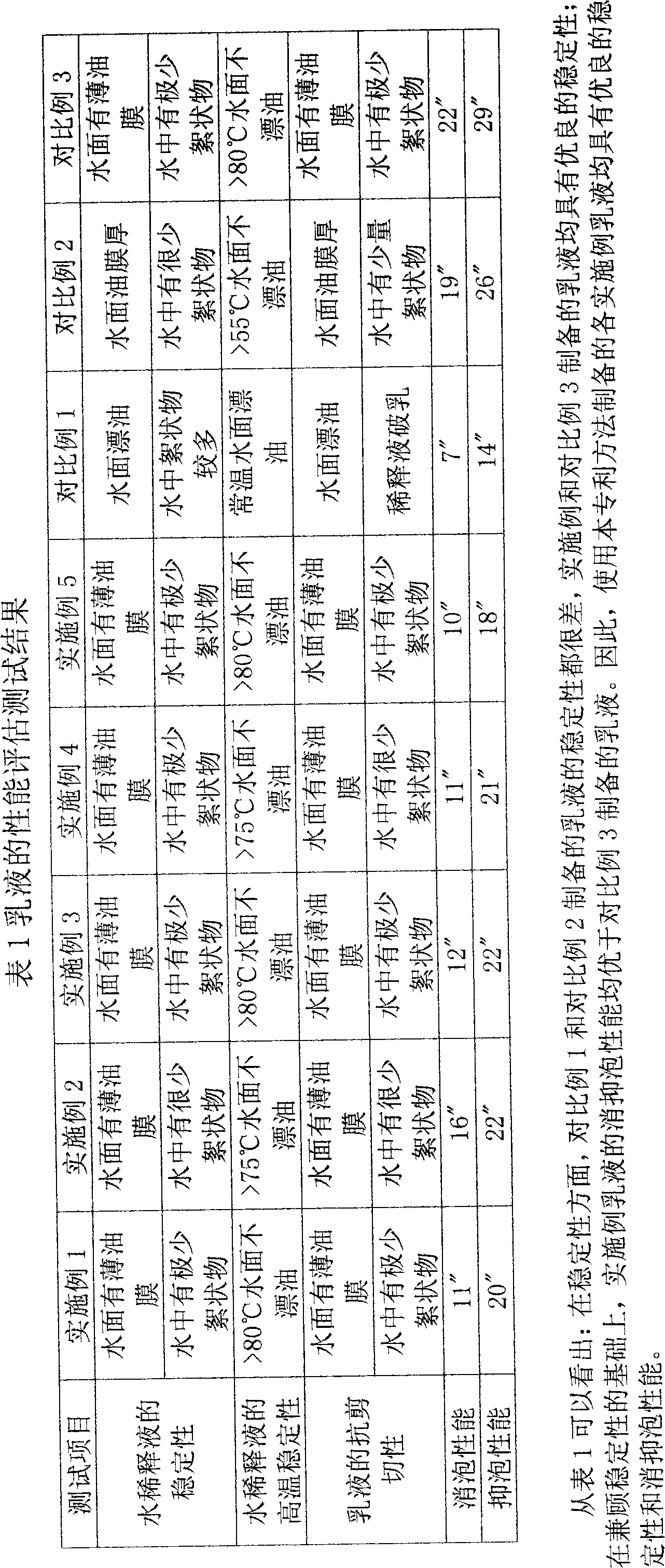

Examples

preparation example Construction

[0039] Preparation of high viscosity silicone composition:

[0040] Refer to the preparation method of Example 1 in US4639489 to prepare a high-viscosity silicone composition: 378g of polydimethylsiloxane with a viscosity of 100,000mPa·s and 180g of polydimethylsiloxane with a viscosity of 10,000mPa·s with hydroxyl groups at both ends Siloxane and 18g tetraethyl orthosilicate were put into the reaction kettle bottle, heated to 130-140°C, and then 3g catalyst was added thereto (catalyst preparation: 90g polydimethylsiloxane with a viscosity of 1,000mPa·s React with 10g KOH at 120°C for 15min), stir and continue heating. Then, add 30g to it and the specific surface area is 200m 2 / g of white carbon black was homogenized with a homogenizer. The reaction composition was heated to 180° C. and maintained for 4 hours, and cooled to room temperature to obtain a viscous liquid which was a high-viscosity silicone composition with a viscosity of 400,000 mPa·s.

Embodiment 1

[0042] Get 100 parts of high-viscosity silicone composition in embodiment 1, 10 parts of sorbitan monolaurate, 10 parts of polyoxyethylene (40) sorbitan monolaurate, 15 parts of N-90 and 15 parts Part N-28 (polyoxyethylene ether modified polysiloxane, self-produced by Nanjing Sixin Technology Application Research Institute Co., Ltd.); after mixing the above raw materials, circulate in the colloid mill for 35 minutes, and keep the system temperature at 60°C; Slowly add water to it, and add 50 parts of water to obtain an emulsion intermediate with a mass concentration of 75%; raise the temperature of this intermediate to 80°C under stirring, and simultaneously turn on the emulsifier at a speed of 4500rpm and keep it for 35 minutes; then, keep the temperature of the system And the rotation speed of the emulsifier remains unchanged, and 100 parts of water is slowly added, and the mass concentration of the system is 50% at this time; finally, it is diluted with a polyacrylate aqueou...

Embodiment 2

[0044] Get 100 parts of the high-viscosity silicone composition in Example 1, 10 parts of octylphenol polyoxyethylene (30) ether, 10 parts of sorbitan trioleate, 20 parts of N-70 (polyoxyethylene ether modified Polysiloxane, self-produced by Nanjing Sixin Technology Application Research Institute Co., Ltd.); after mixing the above raw materials, circulate in the colloid mill for 40 minutes, keep the temperature of the system at 50 ° C; slowly add water to it, add 60 parts of water, and get Emulsion intermediate, its mass concentration is 70%; This intermediate is heated up to 60 ℃ under agitation, open emulsifier at the same time, rotating speed is 5000rpm, keep 40min; Then, keep system temperature and the rotating speed of emulsifying machine unchanged, slowly Add 150 parts of water, and the mass concentration of the system is 40% at this time; finally dilute it with an aqueous solution of xanthan gum to form an emulsion with a concentration of 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com