Preparation method of high-viscosity organic silicon defoamer

A silicone defoamer, high-viscosity technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of poor foam suppression effect, poor defoaming durability, etc., and achieve excellent defoaming and suppressing performance, lasting The effect of foam regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

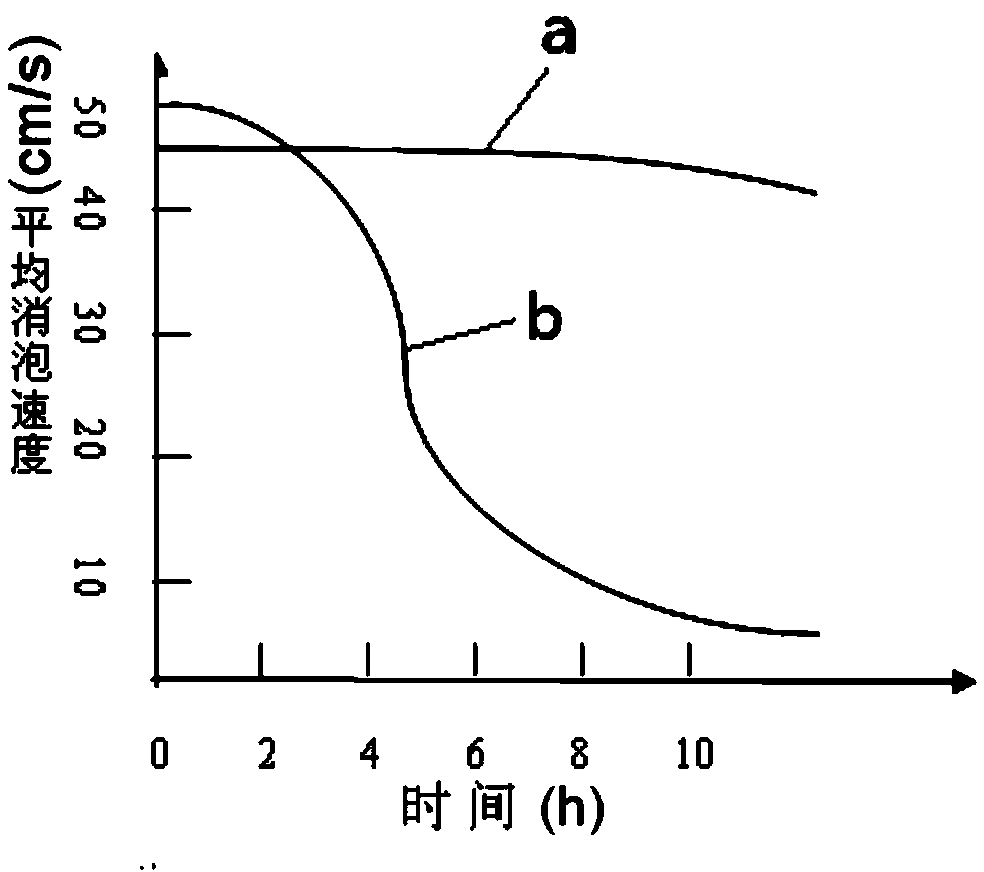

Image

Examples

Embodiment 1

[0024] 1) According to the number of parts by mass, take 8 parts of simethicone oil of 2000cst, 7 parts of simethicone oil of 1 million cst, and 3 parts of specific surface area of 300m 2 / g of hydrophobic fumed silica, 1 part of vinyl trichlorosilane, 12 parts of polyether modified silicone oil, 2 parts of MQ type silicone resin, 3 parts of sorbitan trioleate, 2 parts of polyoxyethylene Sorbitan laurate, 0.2 part of sodium alginate, 0.2 part of mass concentration are 10% sodium hydroxide solution and 65 parts of water; wherein, the n(M) / n(Q) of MQ type silicone resin The ratio is 0.1;

[0025] 2) Add 2000 cst of simethicone oil, 1 million cst of simethicone oil, hydrophobic fumed silica, vinyl trichlorosilane and MQ type silicone resin into a heating tank and raise the temperature to 180 ° C, keep stirring for 3 hours to obtain Silicone paste: Stir and mix the silicone paste, polyether modified silicone oil, sorbitan trioleate and polyoxyethylene sorbitan laurate at 78°C t...

Embodiment 2

[0029] 1) According to the number of parts by mass, take 12 parts of 5000cst simethicone oil, 10 parts of 1 million cst simethicone oil, 1.0 parts of sodium hydroxide, 7 parts of aluminum stearate, 5 parts of polyether modified silicone oil, 2.5 parts MQ type silicone resin, 6.24 parts of sorbitan monostearate, 2.76 parts of cetearyl ether-21, 0.6 part of xanthan gum, 0.9 parts of mass concentration are 10% sodium hydroxide solution and 53 parts of water; Wherein, the ratio of n(M) / n(Q) of MQ type silicone resin is 0.8;

[0030] 2) Add 5000cst simethicone oil, 1 million cst simethicone oil, aluminum stearate, sodium hydroxide and MQ type silicone resin into a heating tank and heat up to 240°C, heat and stir for 1 hour to obtain a silicone paste; Ointment, polyether modified silicone oil, sorbitan monostearate, cetearyl ether-21 were stirred and mixed evenly at 75°C to obtain an oil phase mixture;

[0031] 3) Dissolve xanthan gum in 1 / 2 mass water at 50°C, then add sodium hydr...

Embodiment 3

[0034] 1) According to the number of parts by mass, take 8 parts of 5000cst simethicone oil, 15 parts of 1 million cst simethicone oil, 10 parts of stearic acid amide, 0.1 part of sodium hydroxide, 10 parts of polyether modified silicone oil, 2.01 parts MQ type silicone resin, 4.06 parts of polyoxyethylene sorbitan laurate, 1.94 parts of sodium stearate, 0.6 parts of carboxymethyl cellulose, 0.2 parts of mass concentration are 10% sodium hydroxide solution and 50.1 parts The water; Wherein, the ratio of n(M) / n(Q) of MQ type silicone resin is 0.8;

[0035] 2) Add 5000cst simethicone oil, 1 million cst simethicone oil, stearic acid amide, sodium hydroxide and MQ type silicone resin into a heating tank and heat up to 200°C, heat and stir for 2 hours to obtain a silicone paste; Ointment, polyether modified silicone oil, polyoxyethylene sorbitan laurate, and sodium stearate were stirred and mixed evenly at 72°C to obtain an oil phase mixture;

[0036]3) Dissolve carboxymethyl cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com