Waterproof material for roof and preparation method thereof

A technology of waterproof materials and raw materials, applied in antifouling/underwater coatings, starch coatings, coatings, etc., can solve the problems of affecting the service life of buildings, easy softening and deformation of waterproof materials, disturbing life and production, etc., to achieve improved antibacterial Anti-microbial corrosion, improve adhesion and mechanical properties, optimize the effect of solidification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

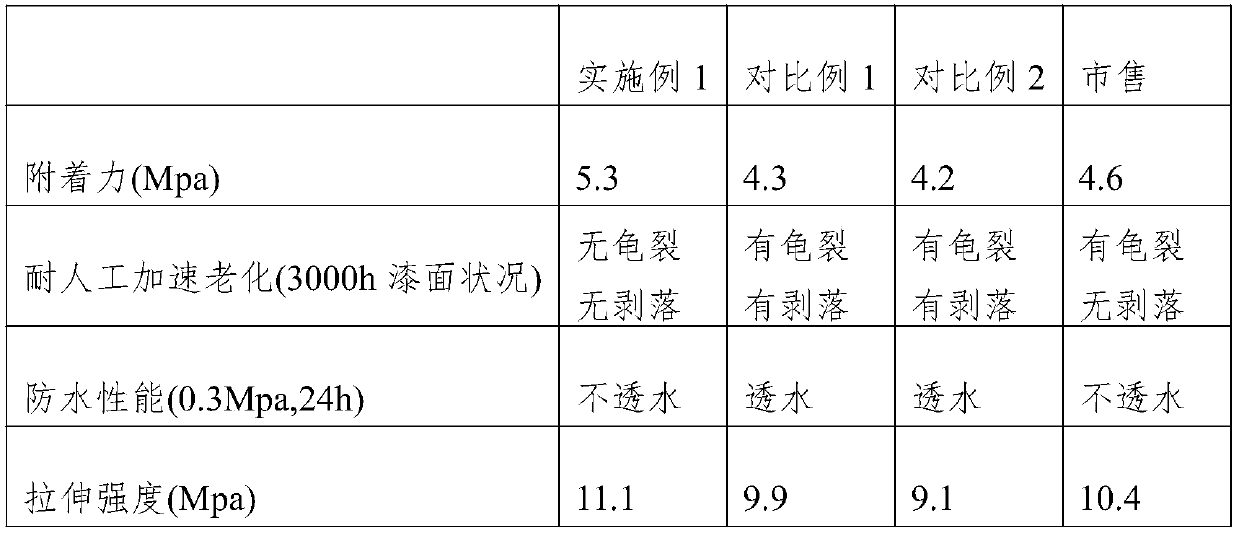

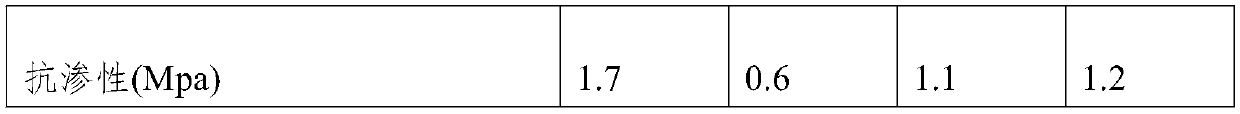

Examples

Embodiment 1

[0025] A waterproof material for the roof, comprising the following raw materials: airgel 15kg, tricresyl phosphate 7kg, butyl acrylate 20kg, ethylene glycol ester 11kg, methyl methacrylate 6kg, glutinous rice flour 17kg, diatom 9kg, carbonic acid Calcium powder 16kg, L-glutamine 8kg, japonica rice flour 10kg, lactic acid 9kg, spirulina 4kg, titanate coupling agent 1.4kg, water 17kg, acid solution 32kg;

[0026] Described acidic solution is made up of following raw material: acetic acid 7kg, tartaric acid 3kg, orange squeezed juice 8kg;

[0027] The squeezed orange juice is obtained by mixing orange pulp and orange peel at a mass ratio of 1:0.3, adding water to a solid-liquid ratio of 1:9, stirring at a speed of 600r / min for 10min, and then stirring at a frequency of 35kHz. Ultrasonic treatment for 25s, filtering 3 times, and combining the filtrates to obtain final product;

[0028] The preparation method of described roof waterproof material, comprises the steps:

[0029] S...

Embodiment 2

[0034] A waterproof material for the roof, comprising the following raw materials: airgel 18kg, tricresyl phosphate 9kg, butyl acrylate 25kg, ethylene glycol ester 14kg, methyl methacrylate 9kg, glutinous rice flour 19kg, diatom 12kg, carbonic acid Calcium powder 18kg, L-glutamine 10kg, japonica rice flour 13kg, lactic acid 11kg, spirulina 5kg, titanate coupling agent 2kg, water 20kg, acid solution 34kg;

[0035] Described acidic solution is made up of following raw material: acetic acid 8kg, tartaric acid 4kg, orange squeezed juice 9kg;

[0036] The squeezed orange juice is obtained by mixing orange pulp and orange peel at a mass ratio of 1:0.4, adding water to a solid-liquid ratio of 1:10, stirring at a speed of 700r / min for 12min, and then mixing the orange peel at a frequency of 40kHz. Ultrasonic treatment for 30s, filtering 3 times, and combining the filtrates to obtain final product;

[0037] The preparation method of described roof waterproof material, comprises the st...

Embodiment 3

[0043] A waterproof material for the roof, comprising the following raw materials: airgel 13kg, tricresyl phosphate 5kg, butyl acrylate 15kg, ethylene glycol ester 8kg, methyl methacrylate 5kg, glutinous rice flour 15kg, diatom 7kg, carbonic acid Calcium powder 13kg, L-glutamine 5kg, japonica rice flour 8kg, lactic acid 7kg, spirulina 2kg, titanate coupling agent 1kg, water 15kg, acid solution 29kg;

[0044] The acid solution is made up of the following raw materials: 5 kg of acetic acid, 2 kg of tartaric acid, and 7 kg of squeezed orange juice;

[0045] The squeezed orange juice is obtained by mixing orange pulp and orange peel at a mass ratio of 1:0.3, adding water to a solid-liquid ratio of 1:9, stirring at a speed of 500r / min for 12min, and then stirring at a frequency of 30kHz. Ultrasonic treatment for 20s, filtering twice, and combining the filtrates to obtain final product;

[0046] The preparation method of described roof waterproof material, comprises the steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com