Active carbon of produced by concentration carbonization papermaking pulping black liquor

A technology for producing activated carbon and activated carbon, which is applied in the field of activated carbon production and can solve the problems of limited development of activated carbon and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

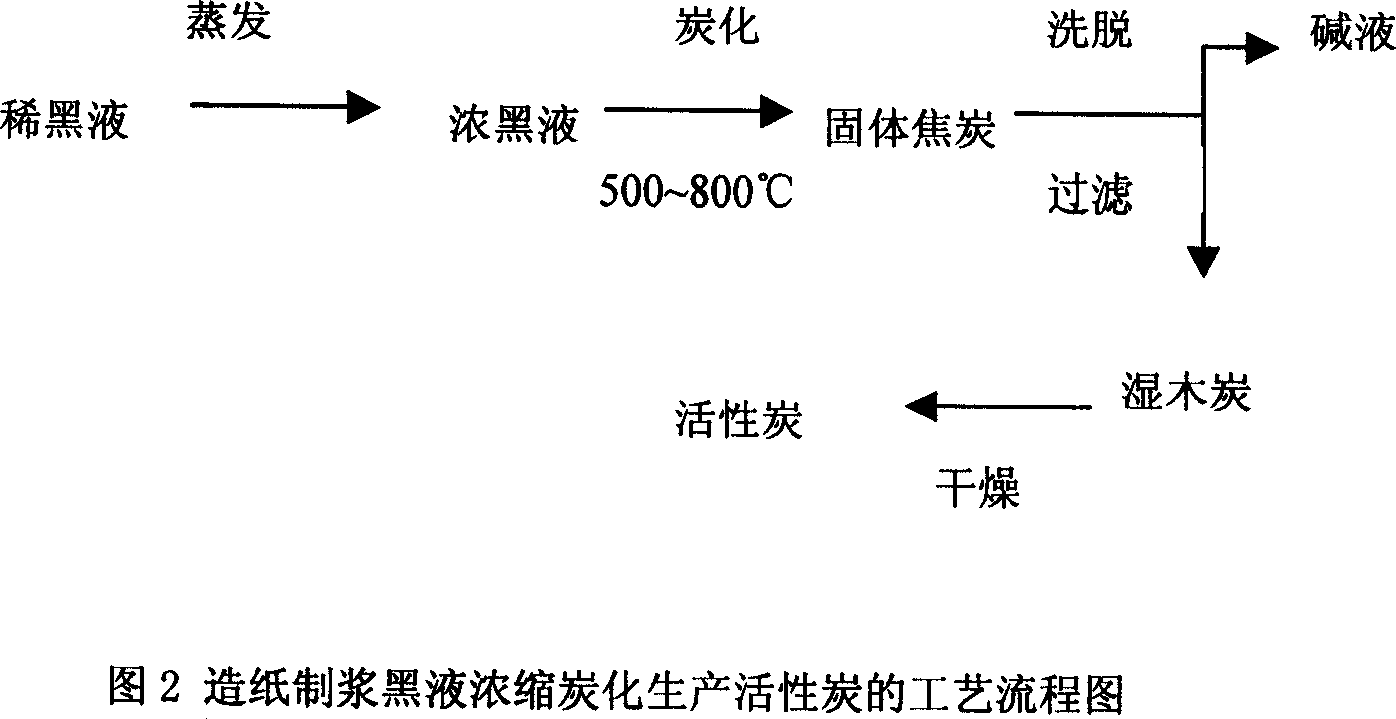

[0009] The sequence process of this treatment method is: the dilute black liquor is evaporated to obtain thick black liquor; the thick black liquor is transferred to a carbonization furnace for carbonization, the carbonization temperature is 500-800°C, and the residence time of the black liquor in the carbonization furnace is 10- After 90 minutes, after carbonization, alkali-containing solid coke is obtained; alkali-containing solid coke contains NaOH, Na 2 CO 3 、Na 2 Alkaline substances such as S are soaked in hot water, eluted, and filtered to obtain wet charcoal powder and alkaline solution; wet charcoal powder is dried to obtain activated carbon. Its technological process is shown in Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com