Pulp making technology through performing biological enzyme softening lignin removal twice combined with mechanical method

A bio-enzyme and delignification technology, which is applied in the direction of using microorganism/enzyme cellulose treatment, cellulose pulp post-treatment, pulp bleaching, etc., can solve the problems of high energy consumption, air pollution, environmental pollution, etc., and achieve operability Strong, targeted, simple and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

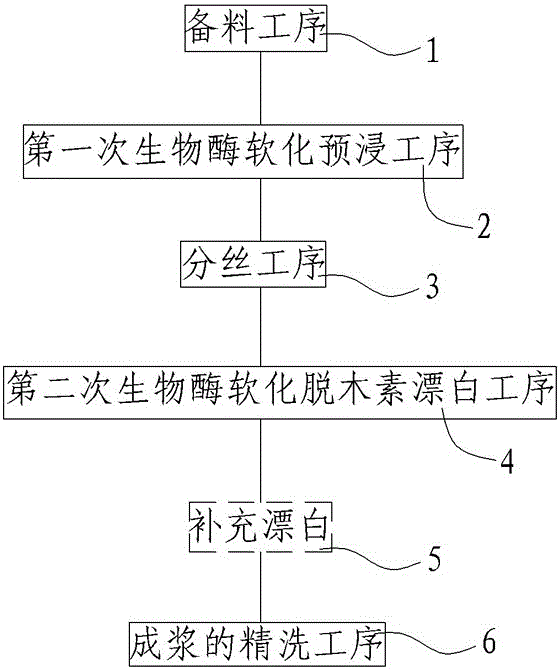

[0035] A two-time bioenzyme softening delignification combined with a mechanical pulping process is carried out sequentially according to the following steps:

[0036] Step 1) Material preparation process 1: cutting, screening and washing of reed raw materials.

[0037] Step 2) The first biological enzyme softening presoaking process 2: fully mix the material, water, compound osmotic softener and compound biological enzyme preparation, react for 1 hour, the reaction temperature is 40°C, and the dosage of the compound osmotic softener is 5 kg / ton The amount of compound biological enzyme preparation is 3 kg / ton of material, and the mass ratio of water to material is 10:3.

[0038] Composite penetration softener is prepared from the following raw materials by weight percentage: sodium alkylsulfonate 5%, triethanolamine oleic acid soap 8%, nonylphenol polyoxyethylene (10) ether 5%, defoamer XD-4000.5% , stearic acid polyoxyethylene (6) ether 20%, polyoxyethylene (5) sorbitan soap...

Embodiment 2

[0050] A two-time bioenzyme softening delignification combined with a mechanical pulping process is carried out sequentially according to the following steps:

[0051] Step 1) Material preparation process: cutting, screening and washing of reed raw materials.

[0052] The material preparation process is as follows: the reed raw material is continuously fed into the grass cutting machine through the conveyor belt, cut into grass pieces, and the grass pieces and impurities are sent to the double cone dust collector by air or conveyor belt to remove the heavier impurities and separate the lighter ones. Impurities, the purified grass pieces are sent to the hydraulic grass cutter by the conveyor to tear the grass pieces, and the shredded grass material, together with water, passes through the sieve plate of the hydraulic grass cutter and is pumped from the bottom of the hydraulic grass cutter to the inclined spiral dehydration machine dehydration, and then through the double-cone d...

Embodiment 3

[0065] A two-time bioenzyme softening delignification combined with a mechanical pulping process is carried out sequentially according to the following steps:

[0066] Step 1) Material preparation process: cutting, screening and washing of reed raw materials.

[0067] The material preparation process is as follows: the reed raw materials are put into the hydraulic grass cutter, the whole grass stalk is broken and the grass leaves are shredded, and the shredded grass and water pass through the sieve plate of the hydraulic grass cutter from the bottom of the hydraulic grass cutter. It is pumped to the oblique screw dehydrator for dehydration, and then further dehydrated by the double-cone disc press to complete the material preparation. The dehydrated sewage is purified and removed for recycling; the rope is removed through the rope removal device installed above the hydraulic grass cutter, and heavy impurities are removed. The debris left on the sieve plate enters the debris ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com