Method for producing pulp and lignin

a technology of lignin and pulp, which is applied in the field of methods for producing pulp and lignin, can solve the problems of loss of cellulose, adversely affecting yield, and destruction of a large amount of natural form lignin from wood chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

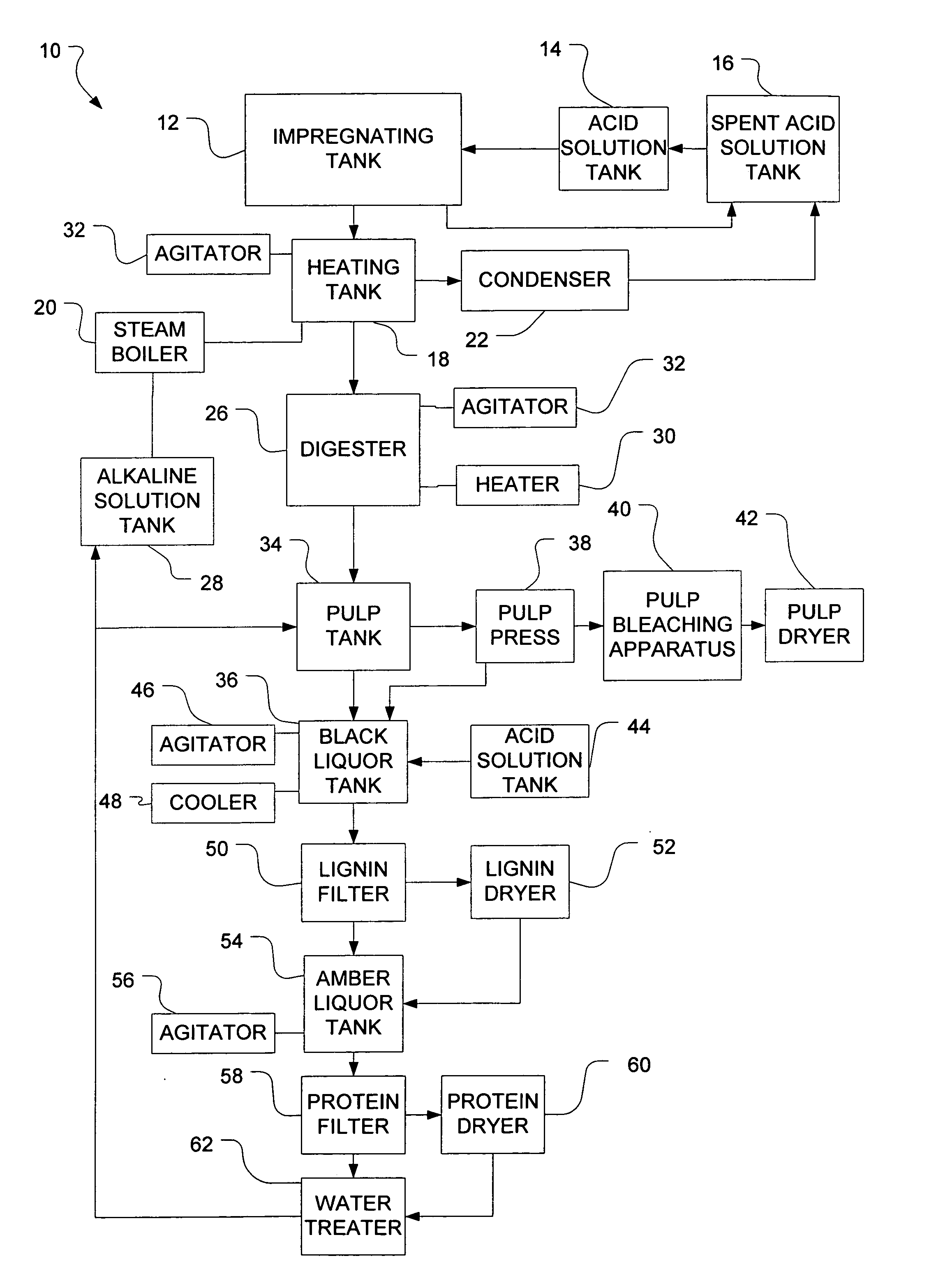

Method used

Image

Examples

example 2

[0104] This example comprised a trial that was similar to Trials 1-19 in example 1 except that the starting lignocellulosic material was 150 grams of shavings and sawdust from Hemlock, Oak and Pine tree species. Impregnation was done for 30 minutes in 15% (w / w) HNO.sub.3 solution under heat of 50.degree. C. The impregnated shavings and sawdust were heated for 60 minutes between 50-75.degree. C., and then for 10 minutes over 80.degree. C. Following the heating step, the shavings and sawdust were contacted with an alkaline solution having 1.25 moles of NaOH and 2600 mL total volume at a temperature of 52.degree. C. for 7 minutes. Following pulp removal, lignin was precipitated with the addition of 20% (v / v) H.sub.2SO.sub.4 The pulp and lignin were not weighed, but a visual inspection showed satisfactory appearance and yield for each, proving that the method of this invention can be carried out with relatively small pieces of lignocellulosic material such as shavings and sawdust.

example 3

[0105] The pulp samples produced in Trials 5, 7 and 2 from example 1 were subsequently analyzed to determine the relative amounts of alpha cellulose, beta cellulose and gamma cellulose therein. The results are found in Table 6 below.

6 TABLE 6 Trial 5 Trial 7 Trial 2 Alpha Cellulose (%) 81.3 79.6 79.2 Beta Cellulose (%) 4.4 3.7 7.5 Gamma Cellulose (%) 14.3 16.7 13.3

[0106] In addition to the methods herein, the present invention also includes pulp produced according to the methods herein, as well as paper products comprising cellulose from pulp produced according to the methods herein. Similarly, the present invention also includes lignin produced according to the methods herein, as well as numerous other products and compositions comprising lignin produced according to the methods herein, including for example, fertilizers, asphalt emulsifiers, soil stabilizers, wood products (such as plywood and particle board), oil well drilling fluids and dispersing agents for preparing concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com