Pretreatment method of wood fiber raw materials

A lignocellulosic raw material and pretreatment technology, which is applied in the direction of pretreatment with acidic compounds, can solve the problems of no thermoplastic performance, limited industrial application, wide molecular weight distribution, etc., and achieve the effect of reducing waste water discharge, high added value, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

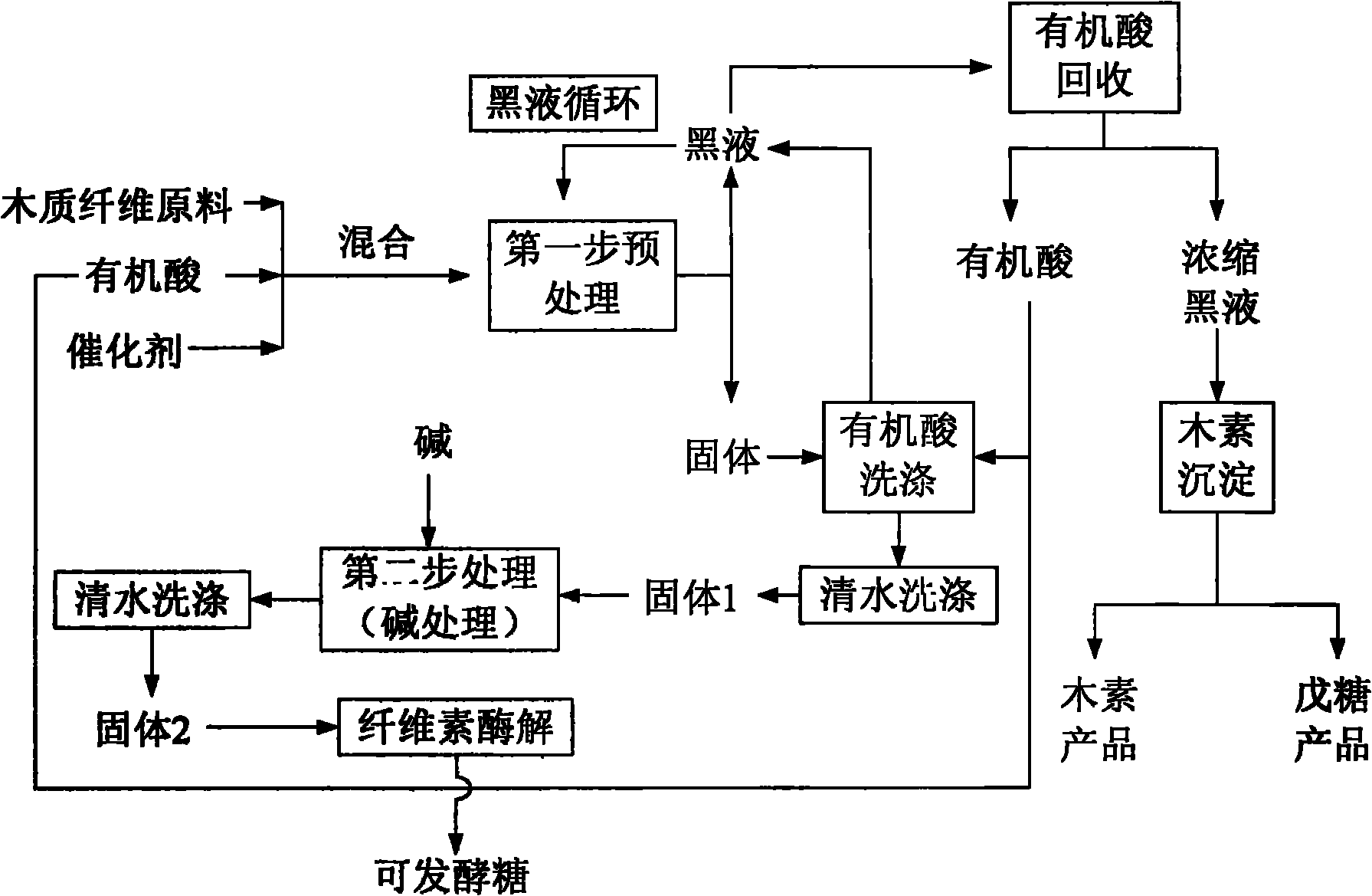

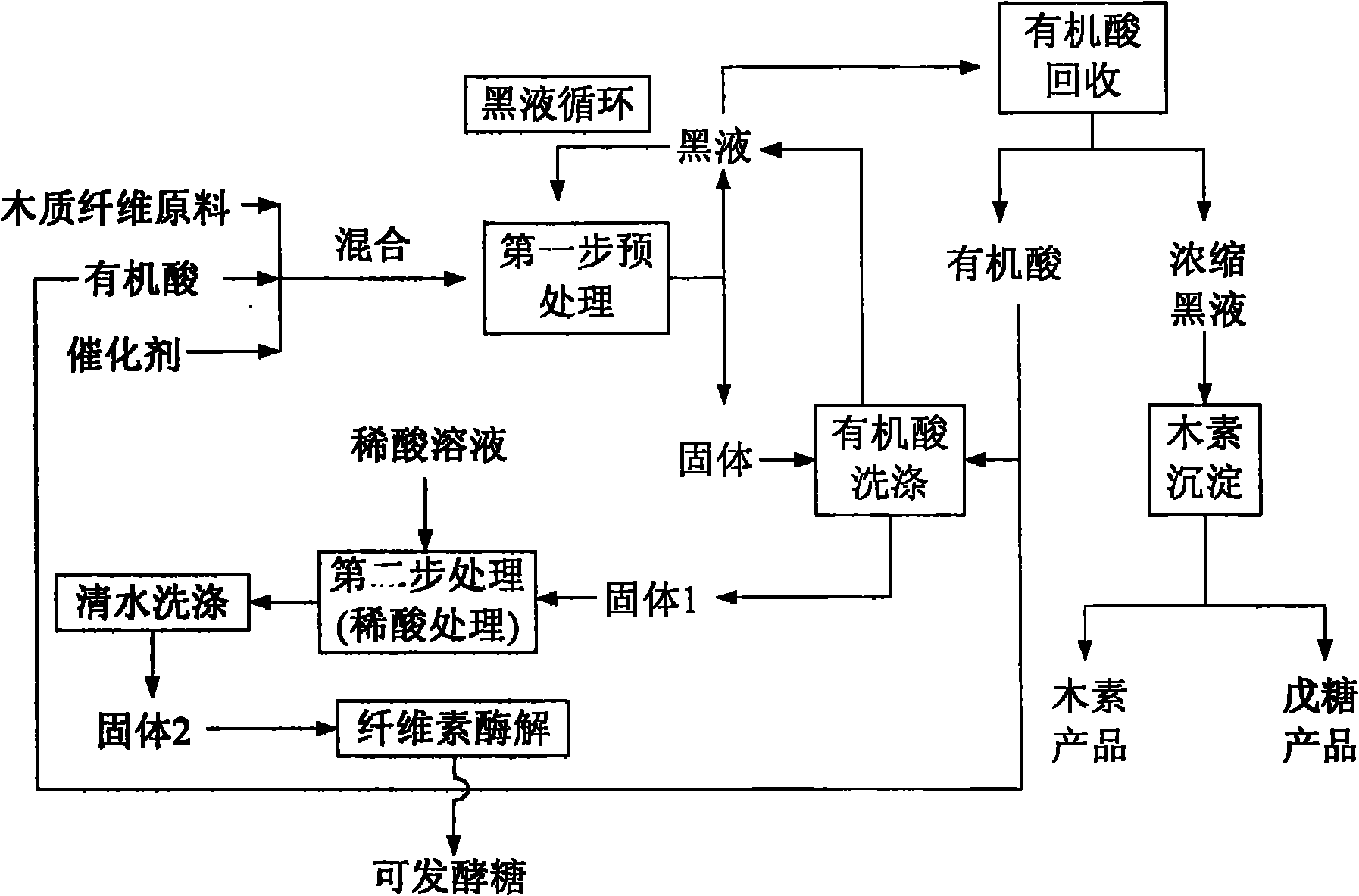

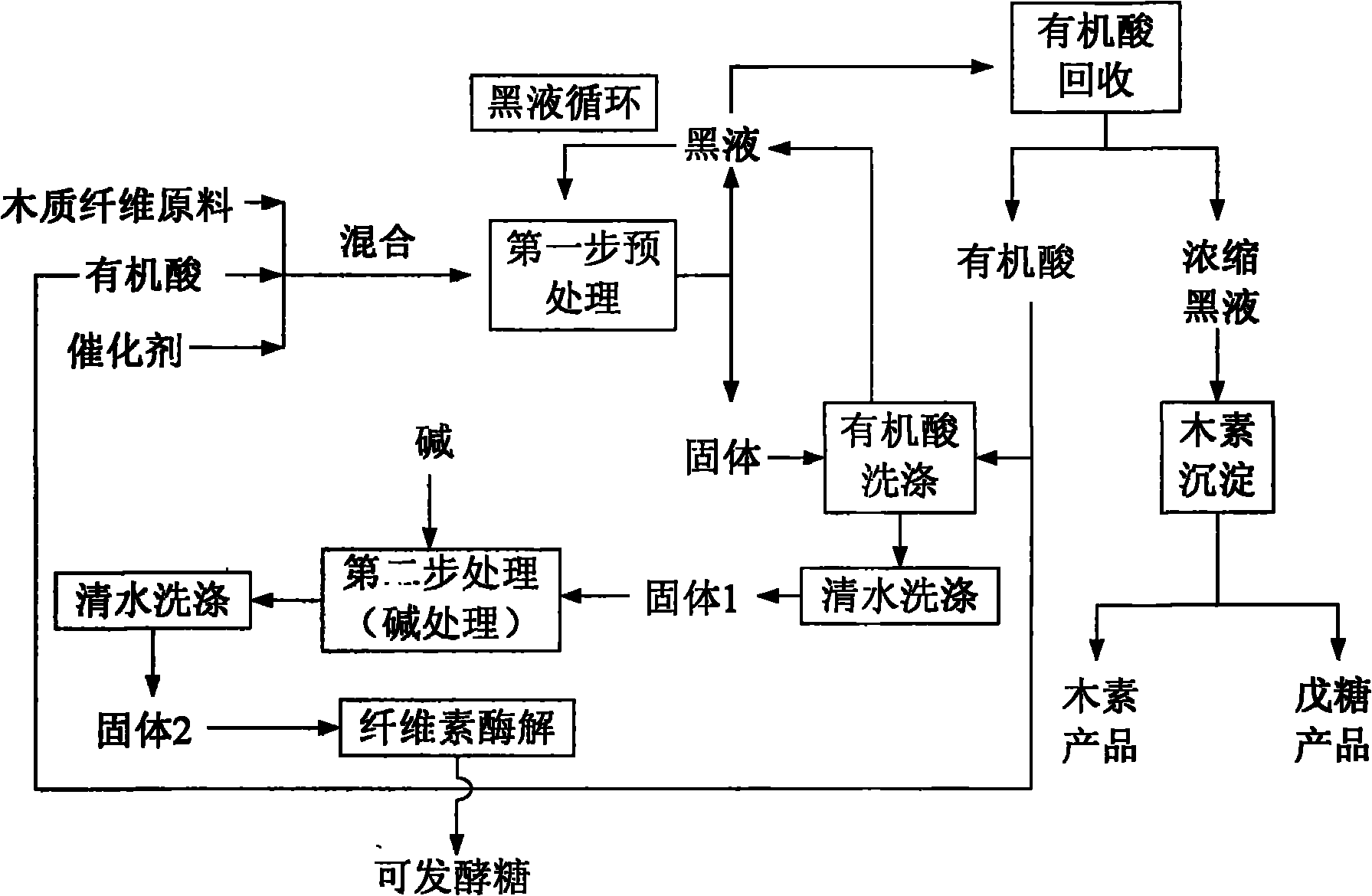

Method used

Image

Examples

Embodiment 1

[0029] The lignocellulosic raw material used is bagasse, and the place of origin is Nanning, Guangxi. The bagasse is air-dried and sieved to remove the small-sized marrow cells, and the part whose particle size is larger than 60 mesh sieve aperture is selected as the raw material. With reference to "Pulp and Paper Analysis and Detection" (Shi Shulan. Pulp and Paper Analysis and Detection. Beijing: China Light Industry Press, 2003.), the bagasse components are analyzed with reference to the relevant measurement method, and the analysis results are: in the bagasse, The ash content is 1.38%, the hot water extract is 5.16%, the 1% NaOH extract is 34.20%, the benzene-alcohol extract is 3.17%, the cellulose content is 44.98%, and the cellulose content is 76.76%. The acid-insoluble lignin content is 18.45%, and the acid-soluble lignin content is 1.80%.

[0030]In the formic acid solution with a mass fraction of 68%, add sulfuric acid with a mass fraction of 0.2% as a catalyst, mix i...

Embodiment 2

[0032] The lignocellulosic raw material used is the same as embodiment 1.

[0033] In the formic acid solution with a mass fraction of 78%, add sulfuric acid with a mass fraction of 0.1% as a catalyst, mix it with bagasse at a liquid-solid ratio of 8:1, and then stir and treat it at normal pressure boiling point (about 105° C.) for 1.5 hours. After cooling and centrifuging to remove the black liquor, use a formic acid solution with a mass fraction of 78% to wash the resulting cellulose solid in a ratio of 8:1 with the initial bagasse liquid-solid ratio. After removing the washing black liquor by centrifugation, wash the solid with clear water to neutral , placed at 105 ° C and dried. The solid yield of the obtained cellulose is 49.2%, the content of glucan is 83.8%, the content of xylan is 7.53%, the content of lignin is 15.65%, and the content of formyl is 4.08%. This cellulose solid adopts the cellulase of 20FPU / gDS (absolutely dry substrate) and the β-glucosidase enzyme hy...

Embodiment 3

[0035] The lignocellulosic raw material used is the same as embodiment 1.

[0036] Add sulfuric acid with a mass fraction of 0.3% as a catalyst in an acetic acid solution with a mass fraction of 70%, mix it with bagasse at a liquid-solid ratio of 10:1, stir and treat it at the boiling point at normal pressure for 3.0 hours, cool and centrifuge to remove black Wash the obtained cellulose solid with 70% acetic acid solution with a mass fraction of 70% according to the liquid-solid ratio of the initial bagasse in a ratio of 10:1, centrifuge to remove the washing black liquor, wash the solid with water to neutrality, and place it at 105°C Tumble dry. The solid yield of the obtained cellulose is 52.4%, the content of glucan is 65.78%, the content of xylan is 15.10%, the content of lignin is 12.61%, and the content of acetyl group is 2.67%. This cellulose solid adopts the cellulase of 20FPU / gDS (absolutely dry base) and the β-glucosidase enzyme hydrolysis of 40CBU / gDS to hydrolyze ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com