Preparation method of lignin phenolic resin

A technology of phenolic resin and lignin, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of purity and methylol content, and achieve equipment saving and process simplification , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

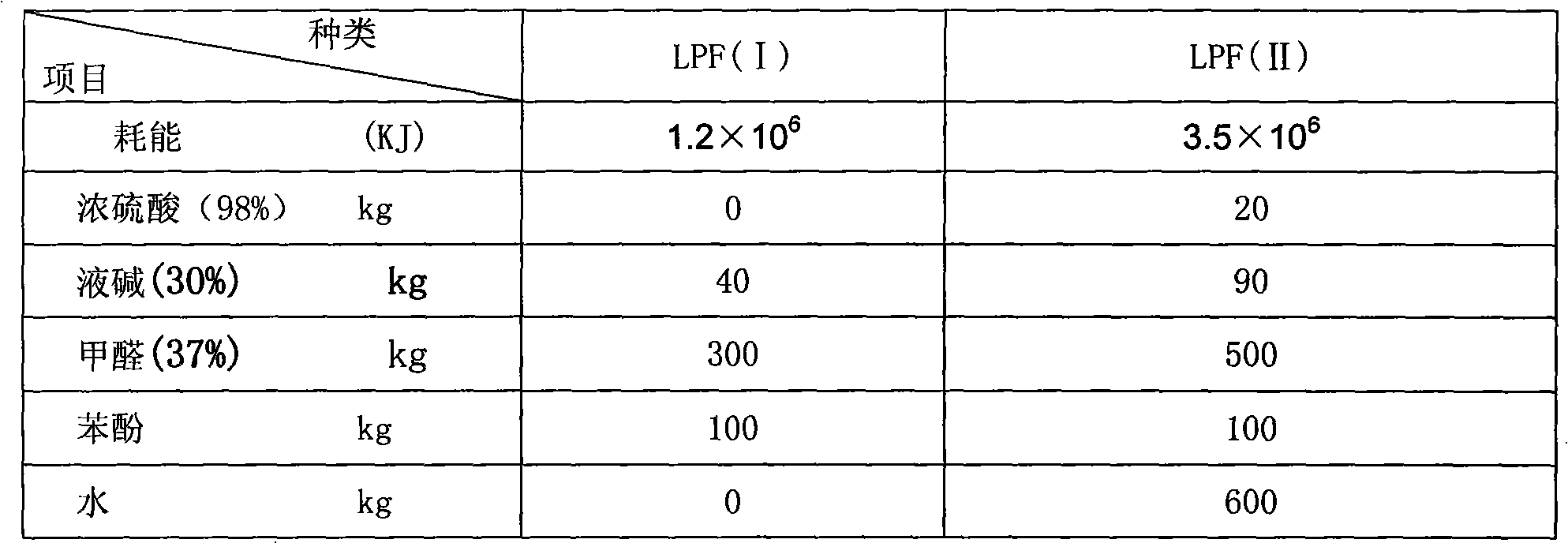

Examples

Embodiment Construction

[0036] Non-limiting examples are described as follows:

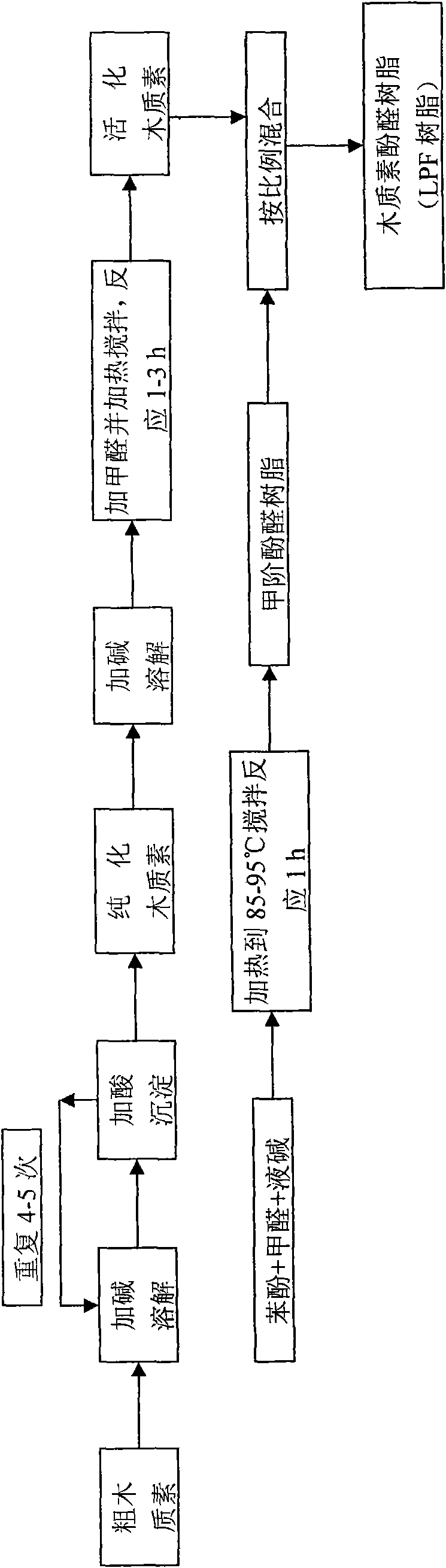

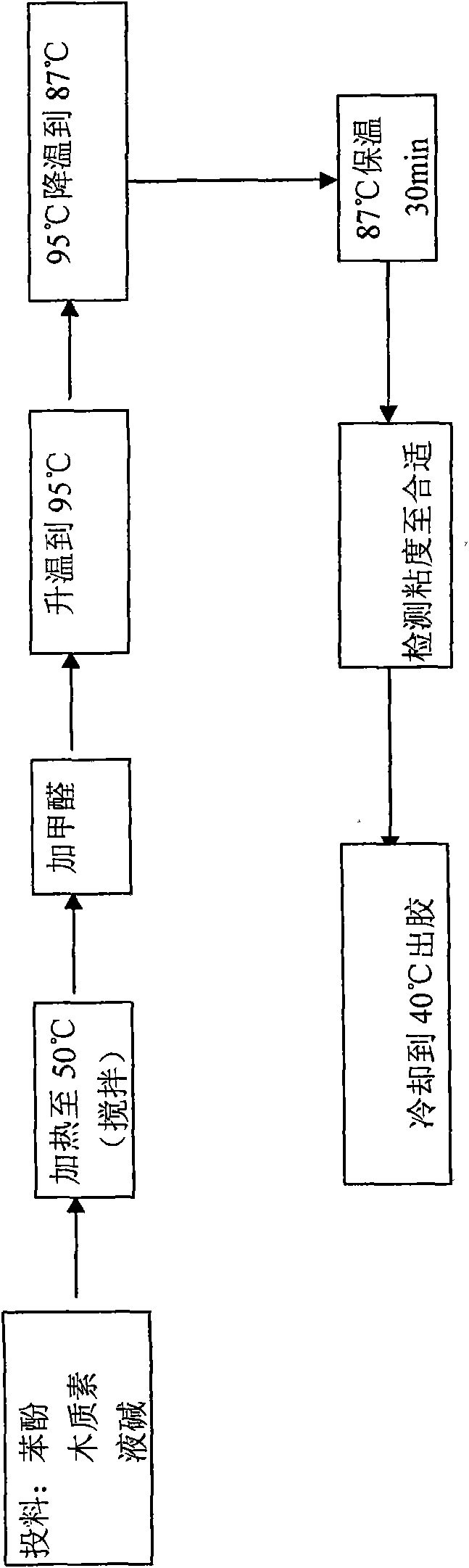

[0037] (1) Preparation of liquid lignin

[0038] 1. Take bamboo shavings or wheat straw, Wujiesang (Miscanthus Anderss. Miscanthus, Poaceae) and other agricultural and forestry wastes, crush them and put them into the explosion chamber of the steam explosion machine in stages, and keep them under the pressure of 1.0MPa ~ 2.5MPa. After pressing for 180s-500s, steam-explode to obtain steam-explosive substances; wash the steam-explosive substances with water, press filter with a rotary screen, take the filter residue and add sodium hydroxide with a mass fraction of 10% of its dry weight, and add 2 to 5 times of water to mix evenly to make the submerged The filter residue is boiled at 85°C to 130°C for 0.5 to 1.5 hours to obtain the alkali boiled product; after cooling, the alkali boiled product is centrifuged to obtain the crude alkali lignin liquid, which is then classified by ultrafiltration membrane and nanofiltration me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com