Method for enhancing properties of carbon fiber-high polymer composite material and product thereof

A composite material, carbon fiber technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the deterioration of carbon fiber-polymer composite material performance, limited degree of composite mechanical properties enhancement, fiber structure and performance damage and other problems, to achieve the effect of improving the interface bonding force, the mechanical strength is significant, and the mechanical strength is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

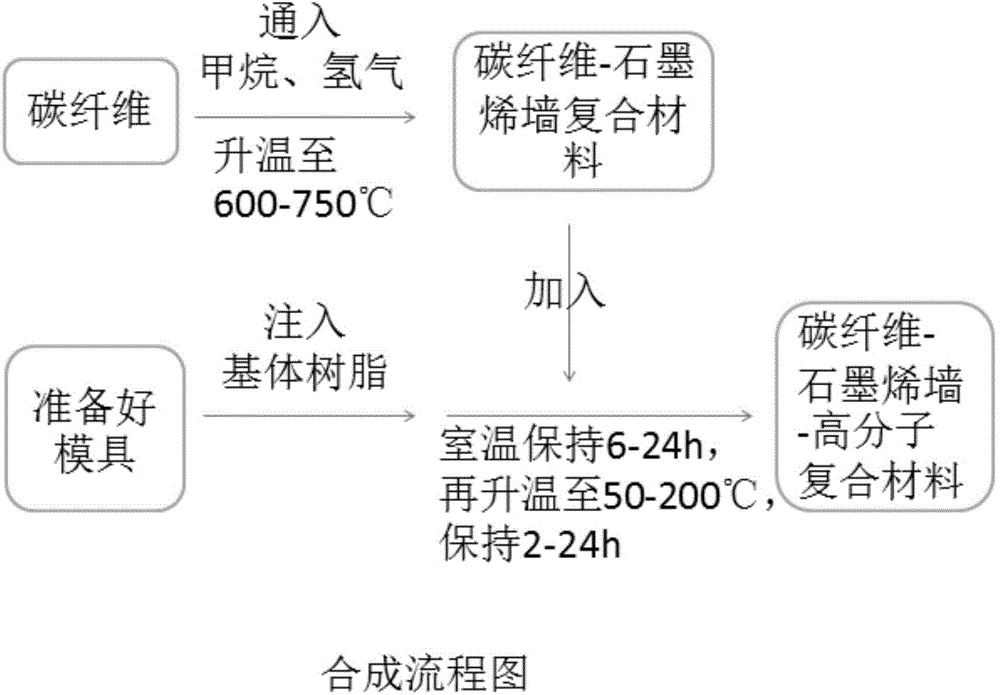

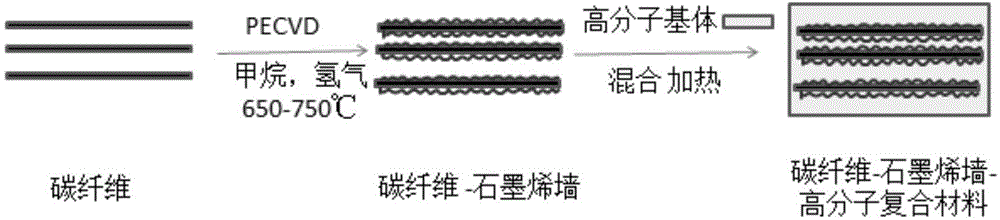

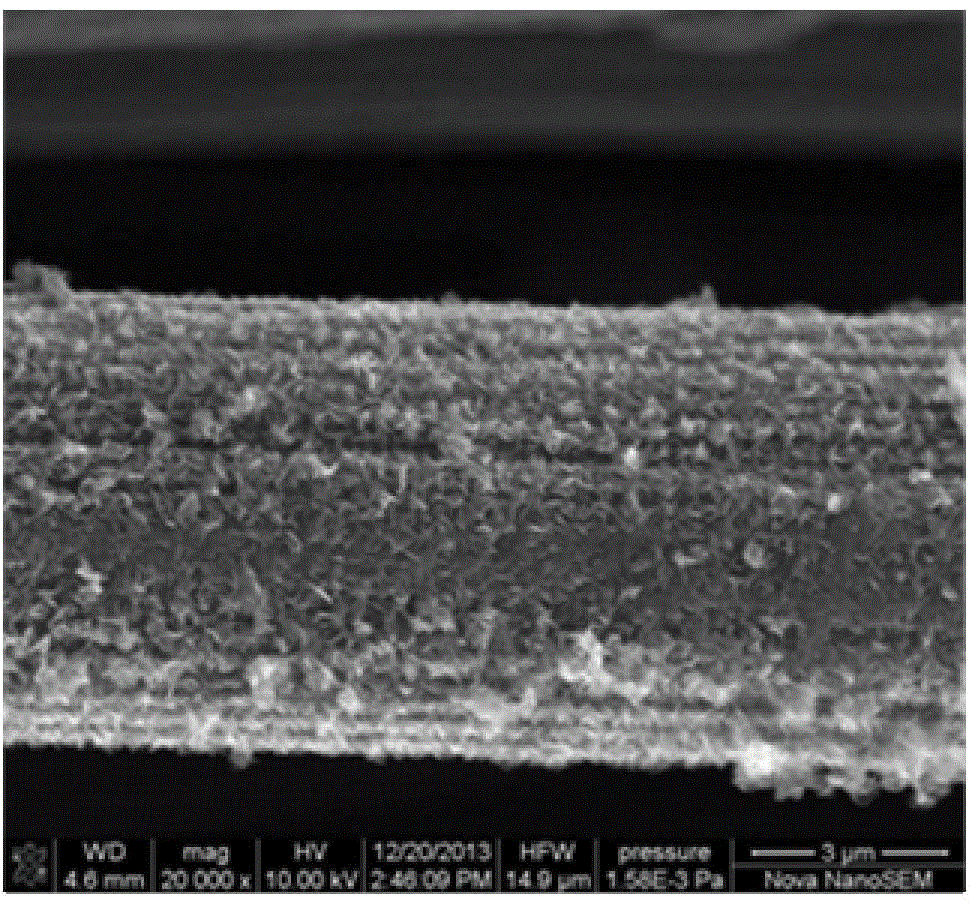

Method used

Image

Examples

Embodiment 1

[0041] A method for enhancing the performance of carbon fiber-polymer composite materials, characterized in that:

[0042] 1) Using carbon fiber, carbon source gas and hydrogen as raw materials;

[0043] 2) Place the carbon fibers in plasma-enhanced chemical vapor deposition equipment; the model of the plasma-enhanced chemical vapor deposition equipment is BTF-1200C, the length of the high-temperature zone is 600mm, and the pipe diameter is 100mm;

[0044] 3) Adjust the parameters of plasma-enhanced chemical vapor deposition equipment: adjust the RF power to 200W, and gradually increase the temperature from room temperature to 750°C in 40 minutes, H 2 The flow rate is 10sccm;

[0045] 4) Keep the temperature and H 2 The flow rate is constant, and annealed for 60 minutes;

[0046] 5) Keep H 2 The flow rate is constant, and the temperature is raised to 800°C in 5 minutes;

[0047] 6) Keep the temperature constant, while feeding carbon source gas and H 2 , adjust H 2 :CH ...

Embodiment 2

[0052] A method for enhancing the performance of carbon fiber-polymer composite materials, characterized in that:

[0053] 1) Using carbon fiber, carbon source gas and hydrogen as raw materials;

[0054] 2) Place the carbon fibers in plasma-enhanced chemical vapor deposition equipment; the model of the plasma-enhanced chemical vapor deposition equipment is BTF-1200C, the length of the high-temperature zone is 600mm, and the pipe diameter is 100mm;

[0055] 3) Adjust the parameters of plasma-enhanced chemical vapor deposition equipment: adjust the RF power to 200W, and gradually increase the temperature from room temperature to 700°C in 40 minutes, H 2 The flow rate is 10sccm;

[0056] 4) Keep the temperature and H 2 The flow rate is constant, and annealed for 60 minutes;

[0057] 5) Keep H 2 The flow rate remains unchanged, and the temperature is raised to 750°C in 15 minutes;

[0058] 6) Keep the temperature constant, while feeding carbon source gas and H 2 , adjust H ...

Embodiment 3

[0063] A method for enhancing the performance of carbon fiber-polymer composite materials, characterized in that:

[0064] 1) Using carbon fiber, carbon source gas and hydrogen as raw materials;

[0065] 2) Place the carbon fibers in plasma-enhanced chemical vapor deposition equipment; the model of the plasma-enhanced chemical vapor deposition equipment is BTF-1200C, the length of the high-temperature zone is 600mm, and the pipe diameter is 100mm;

[0066] 3) Adjust the parameters of plasma-enhanced chemical vapor deposition equipment: adjust the RF power to 200W, and gradually increase the temperature from room temperature to 700°C in 40 minutes, H 2 The flow rate is 15sccm;

[0067] 4) Keep the temperature and H 2 The flow rate is constant, and annealed for 60 minutes;

[0068] 5) Keep H 2 The flow rate remains unchanged, and the temperature is raised to 950°C in 25 minutes;

[0069] 6) Keep the temperature constant, while feeding carbon source gas and H 2 , adjust H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com