Isoprene rubber blend and its preparation method

A technology of isoprene rubber and blends, applied in the field of isoprene rubber blends and their preparation, can solve the problems such as the need for further improvement of anti-fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

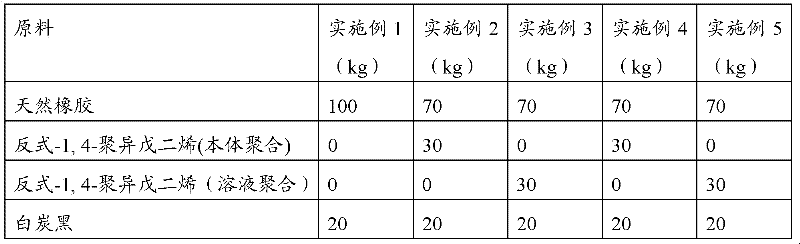

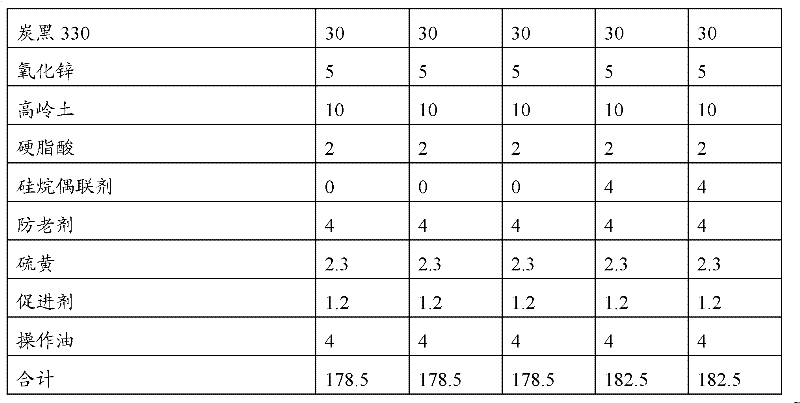

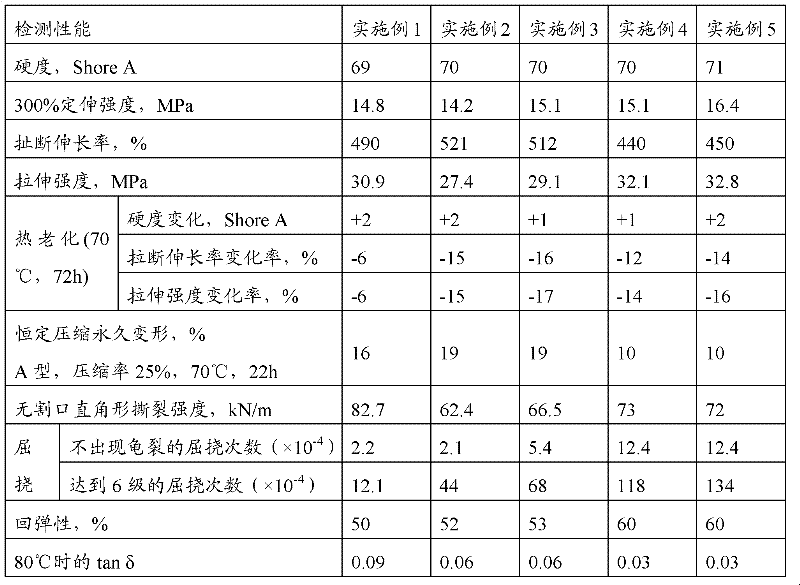

Examples

preparation example Construction

[0040] Correspondingly, the present invention also provides a kind of preparation method of isoprene rubber blend, comprises the following steps:

[0041]After masticating 5-50 parts by weight of trans-1,4-polyisoprene at 60-100°C, with 60-100 parts by weight of isoprene rubber, 5-100 parts by weight of reinforcing filler, 1 ~25 parts by weight of in-situ graft modification auxiliary agent, 0~40 parts by weight of compound rubber and the second additive are mixed at 120~180°C to obtain a masterbatch. The second additive includes active agent, anti-aging One or more of softeners and softeners;

[0042] The masterbatch is mixed with a third additive at 15-100°C to obtain a rubber compound, the third additive includes a vulcanizing agent and / or an accelerator, and the weight sum of the second additive and the third additive is 0 to 25 parts by weight;

[0043] The mix was vulcanized to obtain an isoprene rubber blend.

[0044] In the above preparation method, the isoprene rubb...

Embodiment 6~8

[0063] The preparation of embodiment 6~8 natural rubber / solution polystyrene-butadiene rubber / guttabol blend

[0064] 1. Mix gutta percha in general rubber mixing equipment at 70°C for 3 minutes, then blend with solution polystyrene butadiene rubber and natural rubber, and add various compounding aids except vulcanizing agent and accelerator, Mixed at a high temperature of 140°C for 12 minutes to obtain a masterbatch, the specific raw materials and ingredients are shown in Table 3;

[0065] 2. Park the above masterbatch to cool, when the temperature of the rubber material is within the range of normal temperature -100°C, add vulcanizing agent and accelerator in turn, pass through 3 to 5 times and then release the sheet to obtain the mixed rubber;

[0066] 3. After the rubber mixture was parked for 12 hours, the rubber mixture was vulcanized at 150° C. for 25 minutes to obtain a blend of isoprene rubber.

[0067] The performance results of the isoprene rubber blend prepared in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com