Method for preparing corrosion resistant nickel/chromium plating steel belt

A corrosion-resistant and nickel-plating technology, applied in the field of preparation of high-performance corrosion-resistant nickel/chromium-plated steel strips, can solve the problems of reduced anti-corrosion performance, coating peeling, and high iron exposure rate, so as to improve the interface bonding force and increase anti-corrosion. performance, the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Degreasing the cold-rolled low-carbon steel strip: degreasing is alkali washing and degreasing. , The composition of the chemical degreasing solution is sodium hydroxide 50g / L, sodium carbonate 35g / L, sodium phosphate 25g / L, solution temperature 70°C, current density 4A / dm 2 , Degreasing time 5min.

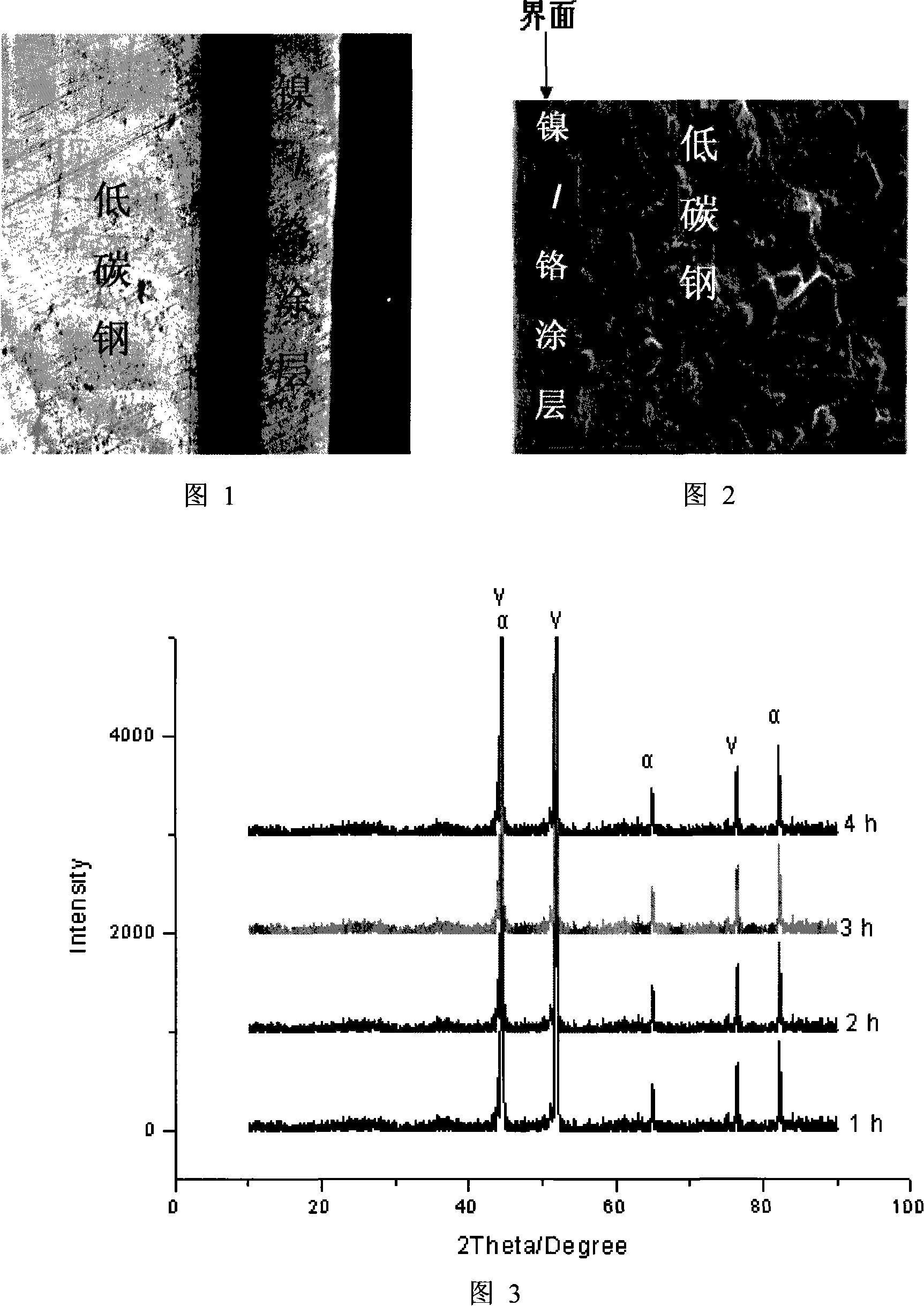

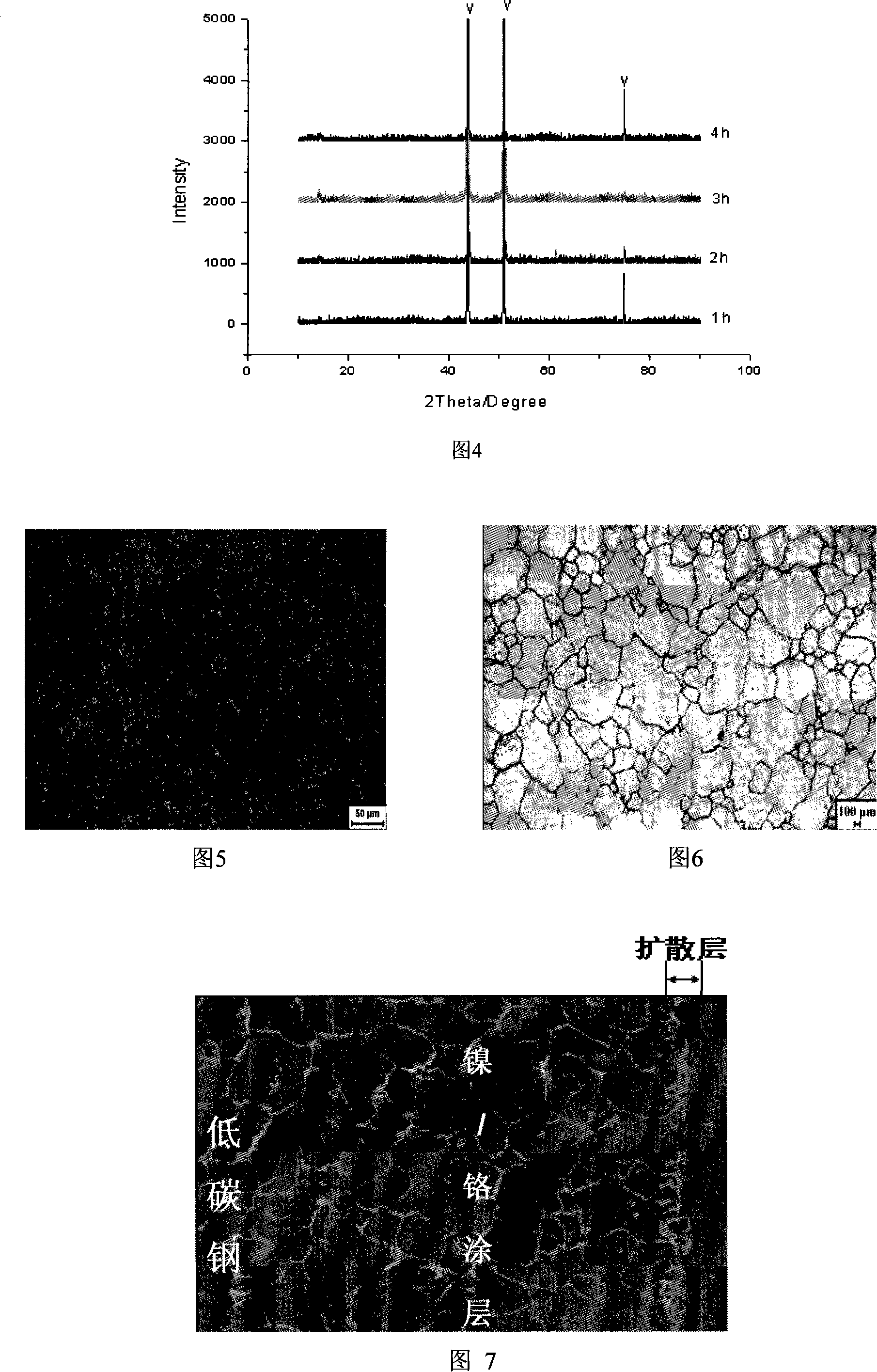

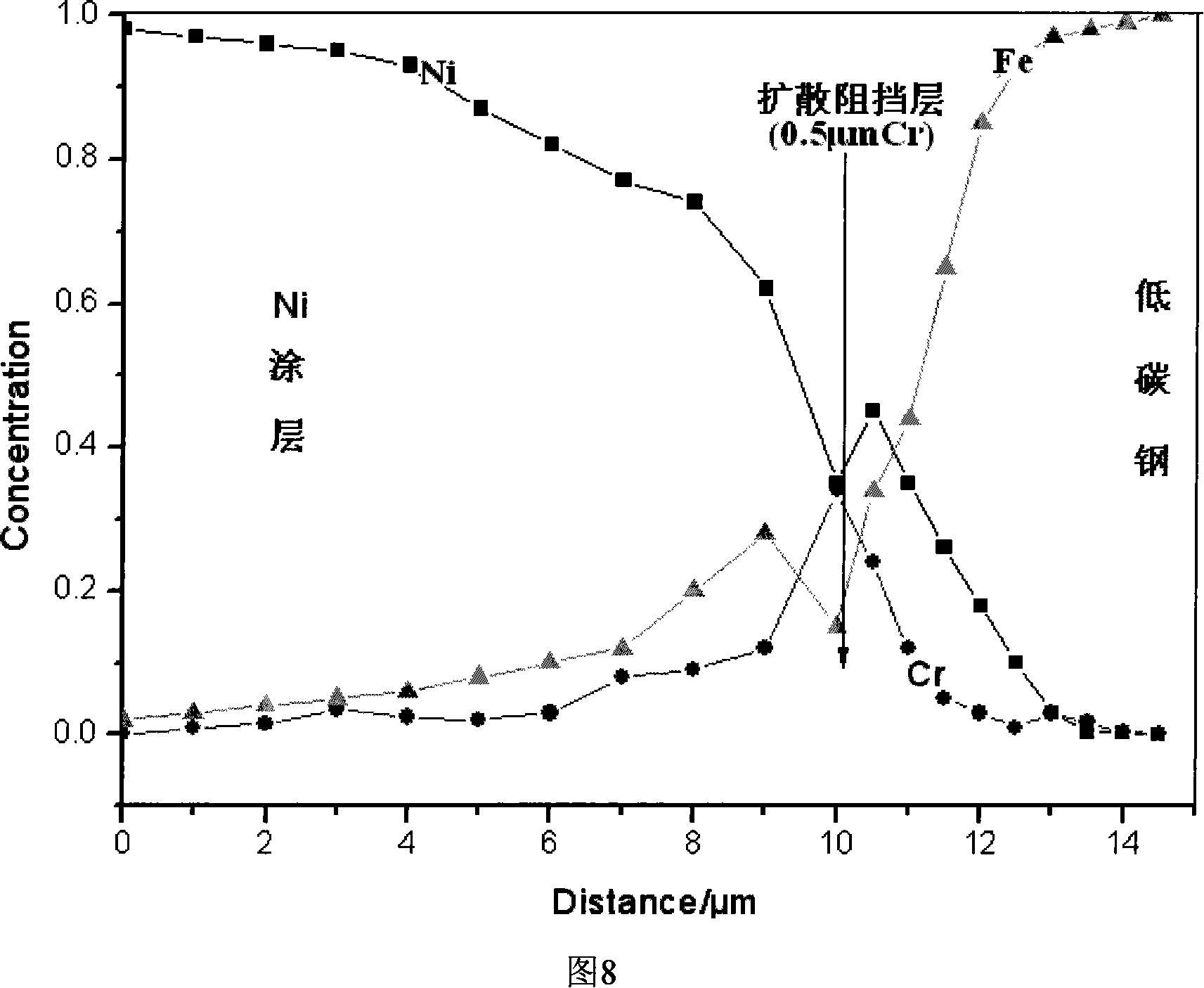

[0037] 2) Put the degreased cold-rolled low-carbon steel strip in the solution tank, and electroplate the chromium layer on the degreased cold-rolled low-carbon steel strip. The thickness of the chromium layer is controlled at 0.01-1 μm: the solution of the electroplated chromium layer The composition is anhydrous chromic anhydride 750g / L, hydrochloric acid 30ml / L, cathode current density 15A / dm 2 , bath temperature 35 ℃, immersion plating time 30s.

[0038] 3) Place the chrome-plated low-carbon steel strip in the solution tank, and electroplate a nickel layer on the chromium-plated low-carbon steel strip. The thickness of the nickel layer is controlled at 10-20 μm: th...

Embodiment 2

[0043] 1) Degreasing the cold-rolled low-carbon steel strip: degreasing is electrolytic degreasing, and electrolytic degreasing is to place the cold-rolled low-carbon steel strip in a solution tank for electrochemical degreasing to further remove the residual grease on the surface and electrolytic degreasing The best solution components are sodium hydroxide 60g / L, sodium carbonate 40g / L, sodium phosphate 45g / L, sodium silicate 4g / L, solution temperature 65°C, current density 6A / dm 2 , Degreasing time 6min.

[0044] 2) Put the degreased cold-rolled low-carbon steel strip in the solution tank, and electroplate the chromium layer on the degreased cold-rolled low-carbon steel strip. The thickness of the chromium layer is controlled at 0.01-1 μm: the solution of the electroplated chromium layer The composition is anhydrous chromic anhydride 800g / L, hydrochloric acid 40ml / L, cathode current density 25A / dm 2 , bath temperature 45 ℃, immersion plating time 3min.

[0045] 3) Place th...

Embodiment 3

[0050] The baseband is made of ordinary Q235 low-carbon steel commonly found in the market, with a thickness of 0.3mm and chemical composition: C 0.14-0.22%, Mn 0.30-0.65%, Si 0.3%, S 0.050%, P 0.045%.

[0051] 1) Degreasing the cold-rolled low-carbon steel strip; degreasing is alkali cleaning and electrolytic degreasing, and the alkali-cleaning degreasing is to place the cold-rolled low-carbon steel strip in a solution tank to remove the grease on the surface of the cold-rolled low-carbon steel strip, The composition of the chemical degreasing solution is sodium hydroxide 60g / L, sodium carbonate 40g / L, sodium phosphate 30g / L, solution temperature 75°C, current density 5A / dm 2 , Degreasing time 5min. Electrolytic degreasing is to place the cold-rolled low-carbon steel strip in a solution tank for electrochemical degreasing to further remove the residual grease on the surface. The components of the electrolytic degreasing solution are sodium hydroxide 50g / L, sodium carbonate 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com