Polyvinylpyrrolidone hybridized graphene catalyst carrier material and preparation method and application thereof

A technology of polyvinylpyrrolidone and catalyst carrier, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., which can solve the problem that the dispersion and size of nano-metals cannot be effectively controlled and cannot be well To meet the needs of catalysts, acid resistance, weak alkali effect and other issues, to achieve the effect of avoiding agglomeration and shedding, uniform dispersion and size, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

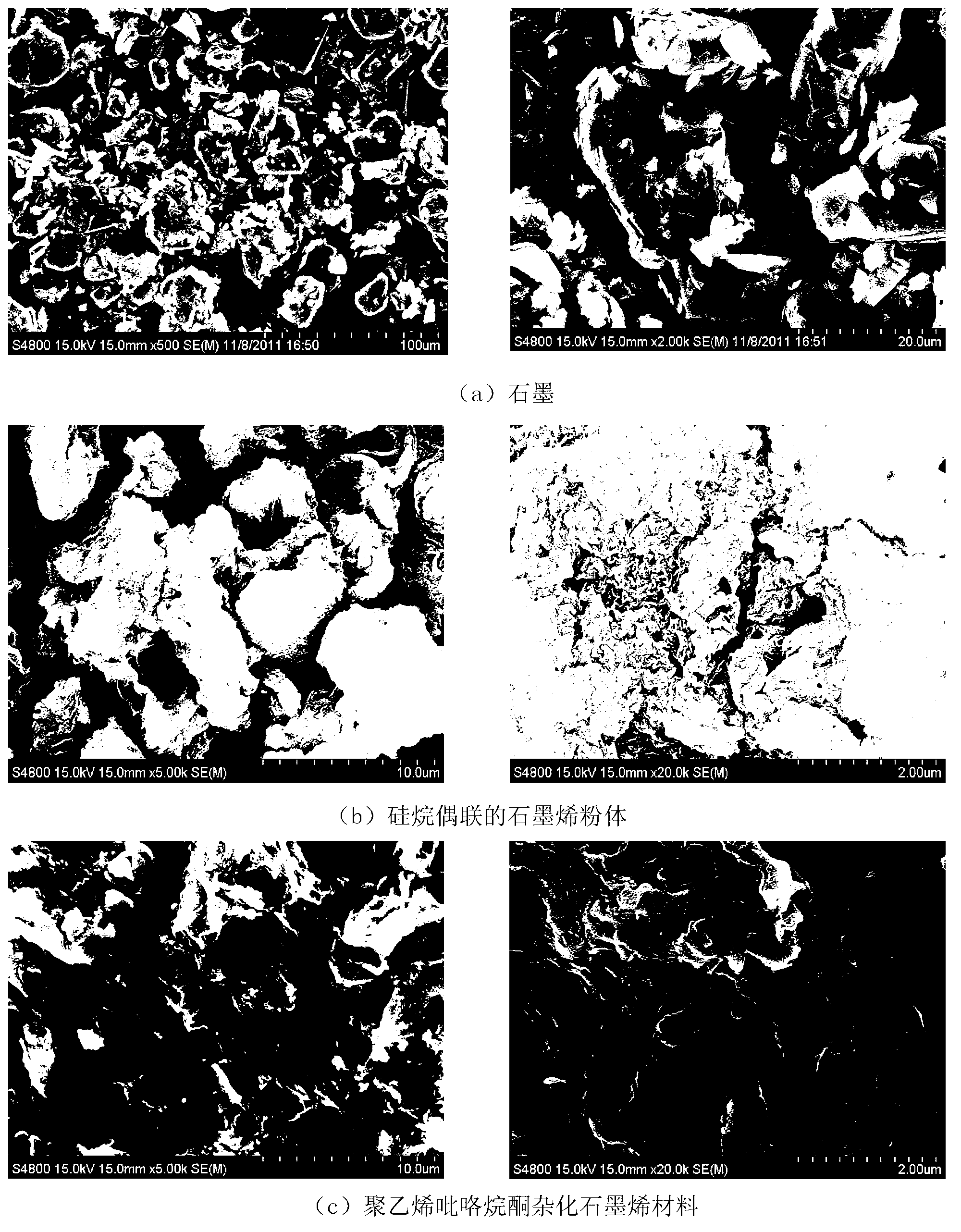

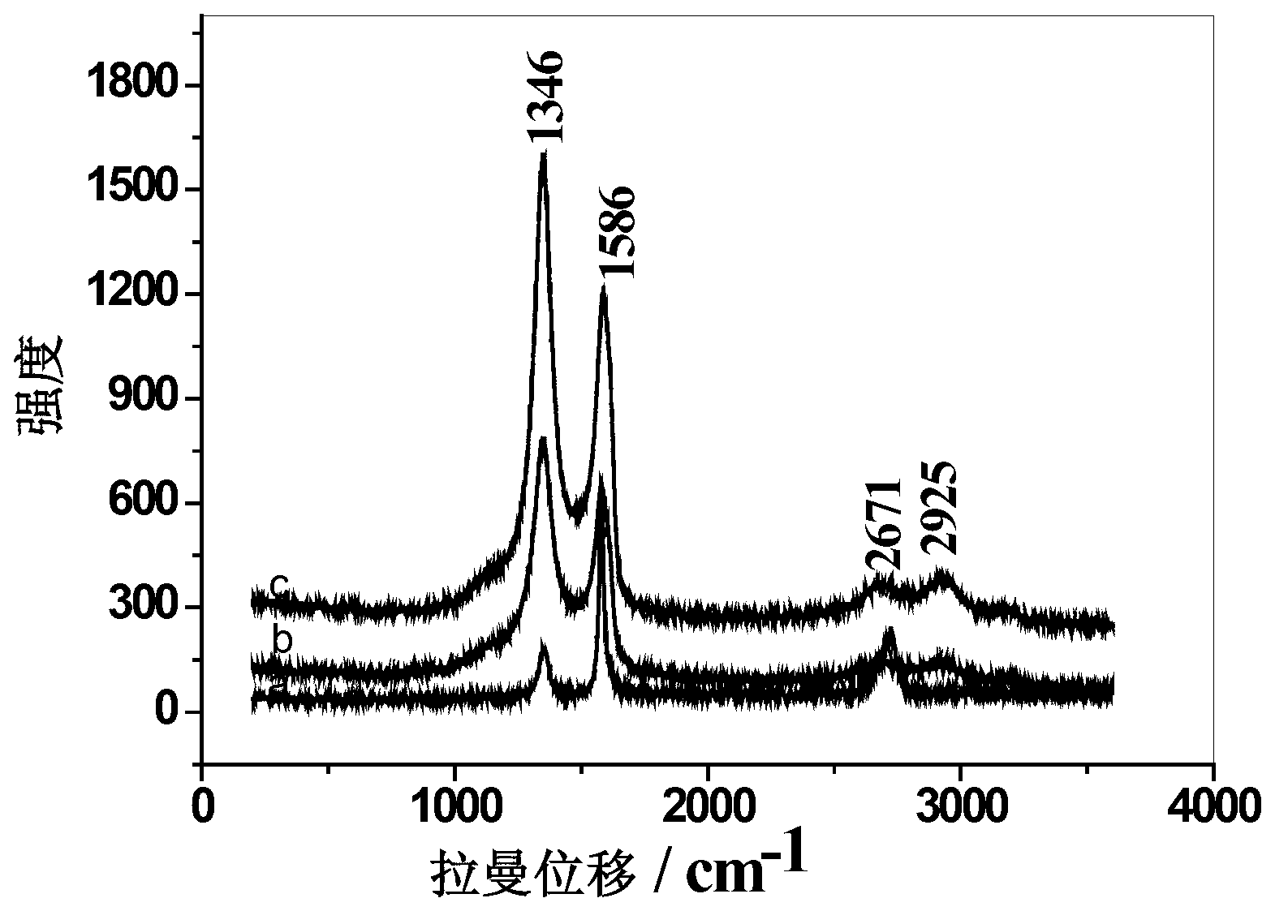

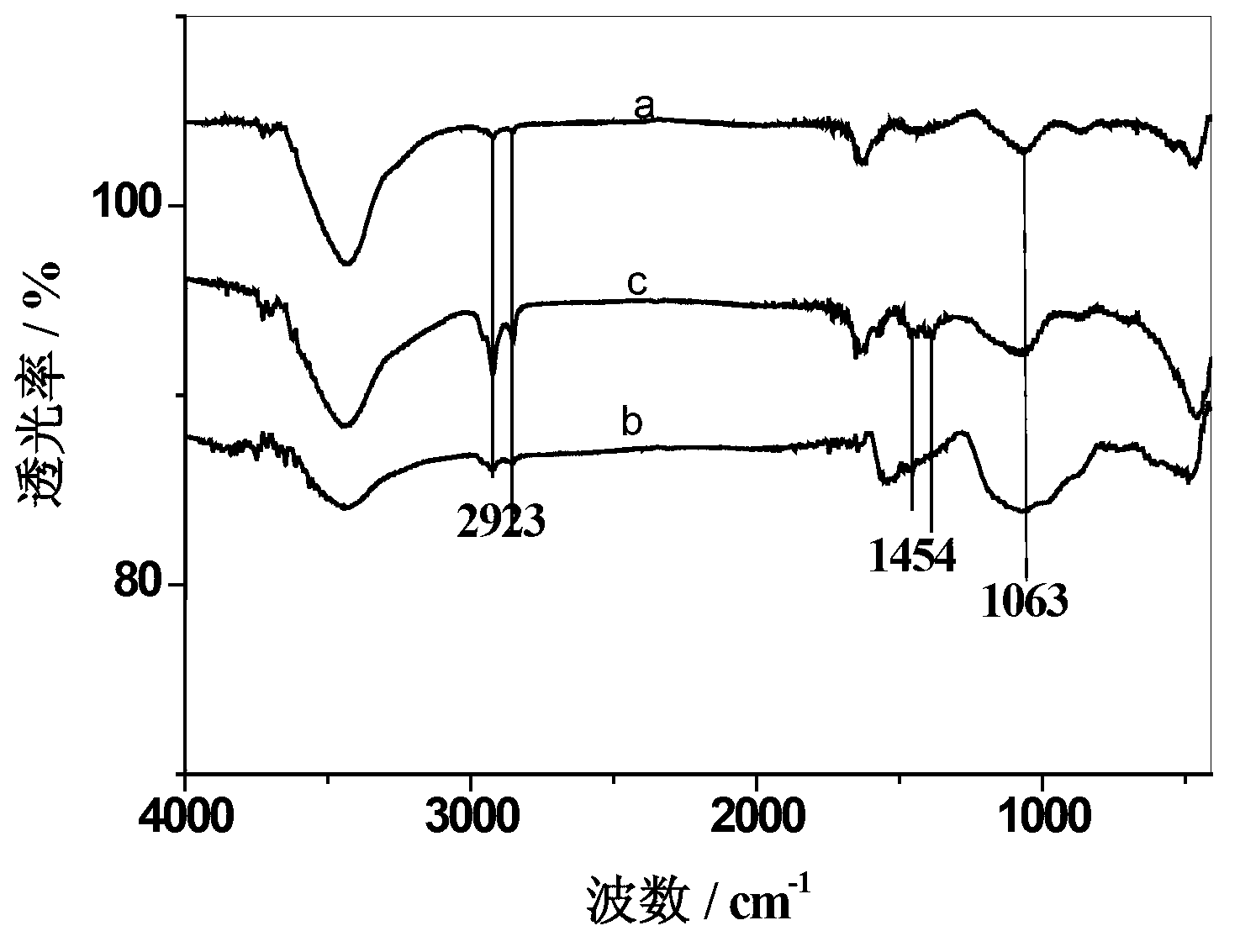

[0033] The polyvinylpyrrolidone hybrid graphene catalyst support material in this embodiment is covalently introduced polyvinylpyrrolidone on the surface of the graphene material.

[0034] The preparation method of this polyvinylpyrrolidone hybrid graphene catalyst carrier material comprises the following steps:

[0035] 1) Add 50g of graphite oxide into 2L of water, ultrasonically disperse for 1h, then adjust the pH of the solution to 4, add 15ml of vinyltrimethoxysilane under an inert atmosphere, and reflux for 24h to obtain a silane dioxide with a double bond at the end. Linked graphene oxide slurry;

[0036] 2) Dilute the obtained silane coupling modified graphene oxide slurry to 3 times with water, under an inert atmosphere, add 0.3L of tetrabutylammonium hydroxide aqueous solution with a mass fraction of 40%, 1L of hydrazine hydrate, and reflux for 10h Then stop the reaction, suction filter, wash to neutrality, and dry at room temperature to obtain a silane-coupled grap...

Embodiment 2

[0039]The polyvinylpyrrolidone hybrid graphene catalyst support material in this embodiment is covalently introduced polyvinylpyrrolidone on the surface of the graphene material.

[0040] The preparation method of this polyvinylpyrrolidone hybrid graphene catalyst carrier material comprises the following steps:

[0041] 1) Add 10g of graphite oxide to 1L of water, ultrasonically disperse for 1h, then adjust the pH value of the solution to 4.5, add 5ml of vinyltriethoxysilane under inert atmosphere conditions, and reflux for 12h to obtain Silane-coupled graphene oxide slurry;

[0042] 2) Dilute the obtained silane coupling modified graphene oxide slurry to 3 times with water, under an inert atmosphere, add 0.3L of tetrabutylammonium hydroxide aqueous solution with a mass fraction of 40%, 1L of hydrazine hydrate, and reflux for 10h Then stop the reaction, suction filter, wash to neutrality, and dry at room temperature to obtain a silane-coupled graphene powder whose end group i...

Embodiment 3

[0045] The polyvinylpyrrolidone hybrid graphene catalyst support material in this embodiment is covalently introduced polyvinylpyrrolidone on the surface of the graphene material.

[0046] The preparation method of this polyvinylpyrrolidone hybrid graphene catalyst carrier material comprises the following steps:

[0047] 1) Add 100g of graphite oxide to 3L of water, ultrasonically disperse for 1h, then adjust the pH of the solution to 5, add 20ml of γ-(methacryloyloxy)propyltrimethoxysilane under inert atmosphere conditions, and reflux for 48h , to obtain a silane-coupled graphene oxide slurry whose end group is a double bond;

[0048] 2) Dilute the obtained silane coupling modified graphene oxide slurry to 3 times with water, under an inert atmosphere, add 0.3L of tetrabutylammonium hydroxide aqueous solution with a mass fraction of 40%, 1L of hydrazine hydrate, and reflux for 10h Then stop the reaction, suction filter, wash to neutrality, and dry at room temperature to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com