High-residual-carbon thermosetting boron-containing phenolic resin as well as preparation method and application thereof

A boron phenolic resin and thermosetting technology, which is applied in the field of high carbon residue thermosetting boron phenolic resin and its preparation, can solve the problems of difficult application, difficult removal, and low ionization potential of sodium atoms, and achieve excellent flame retardancy, improved moisture resistance, The effect of excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

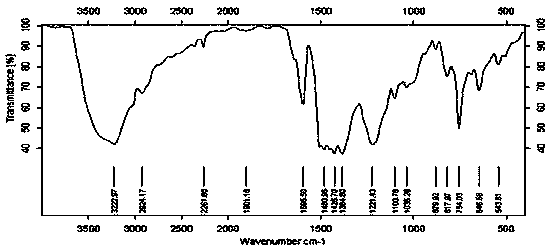

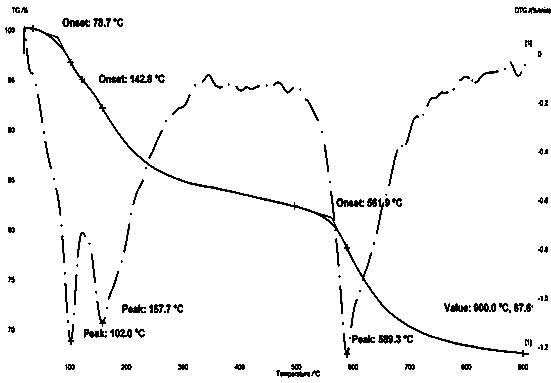

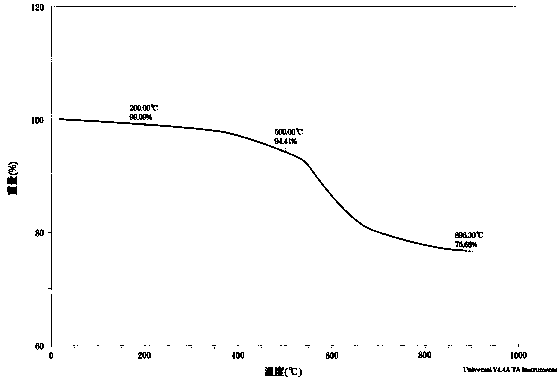

Image

Examples

Embodiment 1

[0030] Esterification stage: add boric acid (chemically pure) and phenol (industrial pure) with a molar ratio of 1:3, namely 123.6g and 564g, into a 1000ml three-necked flask, put the three-necked flask into the oil bath, and then put the oil bath On a temperature-adjustable electric furnace, the three-neck flask is connected to a condenser for dehydration and condensation, and the condensate is collected at the lower port; the temperature is raised to 120°C within 3 hours to synthesize triphenyl borate; when the dehydration amount reaches 85g, stop heating.

[0031] Step 2: cooling stage: cooling the triphenyl borate obtained in step 1, and lowering its temperature to 60°C;

[0032] Step 3: Synthesis of high-carbon residual thermosetting boron phenolic resin stage: replace the synthesis device with a reflux device, when the triphenyl borate is cooled to 60°C, add paraformaldehyde, and open the reflux cooling water. The molar ratio is 1.1, and then the temperature rises. When ...

Embodiment 2

[0035] Esterification stage: Add boric acid and phenol with a molar ratio of 1:3, namely 123.6g and 564g, into a 1000ml three-necked flask, put the three-necked flask into an oil bath, and place the oil bath on an adjustable temperature electric stove. The three-necked flask was connected to a condenser, and the temperature was raised to 140° C. within 3.5 hours to synthesize triphenyl borate. Stop heating when the condensed water reaches 75g. Cooling stage: cooling the triphenyl borate obtained in step 1 to lower its temperature to 60°C;

[0036] The stage of synthesizing high carbon residue thermosetting boron phenolic resin: change the synthesis device into a reflux device, when the triphenyl borate is cooled to 60°C, add paraformaldehyde, the molar ratio of paraformaldehyde to phenol is 1.3, and then heat up , to generate boron phenolic resin; when the temperature rises to 95°C, the phenomenon of automatic heating occurs, at this time, stop accelerating or reduce the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com