Method for preparing superhigh temperature resistant ceramic coat

A technology for ultra-high temperature ceramics and coatings, applied in the field of preparation of ultra-high temperature resistant ceramic coatings, can solve the problems of poor substrate bonding performance, complex process equipment, low coating density, etc., to achieve dense coatings and low preparation temperatures , preparation process and equipment require simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An ultra-high temperature resistant ceramic coating is prepared by the following steps:

[0021] Step 1: Set the density to 1.70g / cm 3 The surface of the dense three-dimensional C / C composite material was polished and smoothed, using acetone as the medium, ultrasonic cleaning for 30 minutes, and drying in an oven at 80 °C for 3 hours;

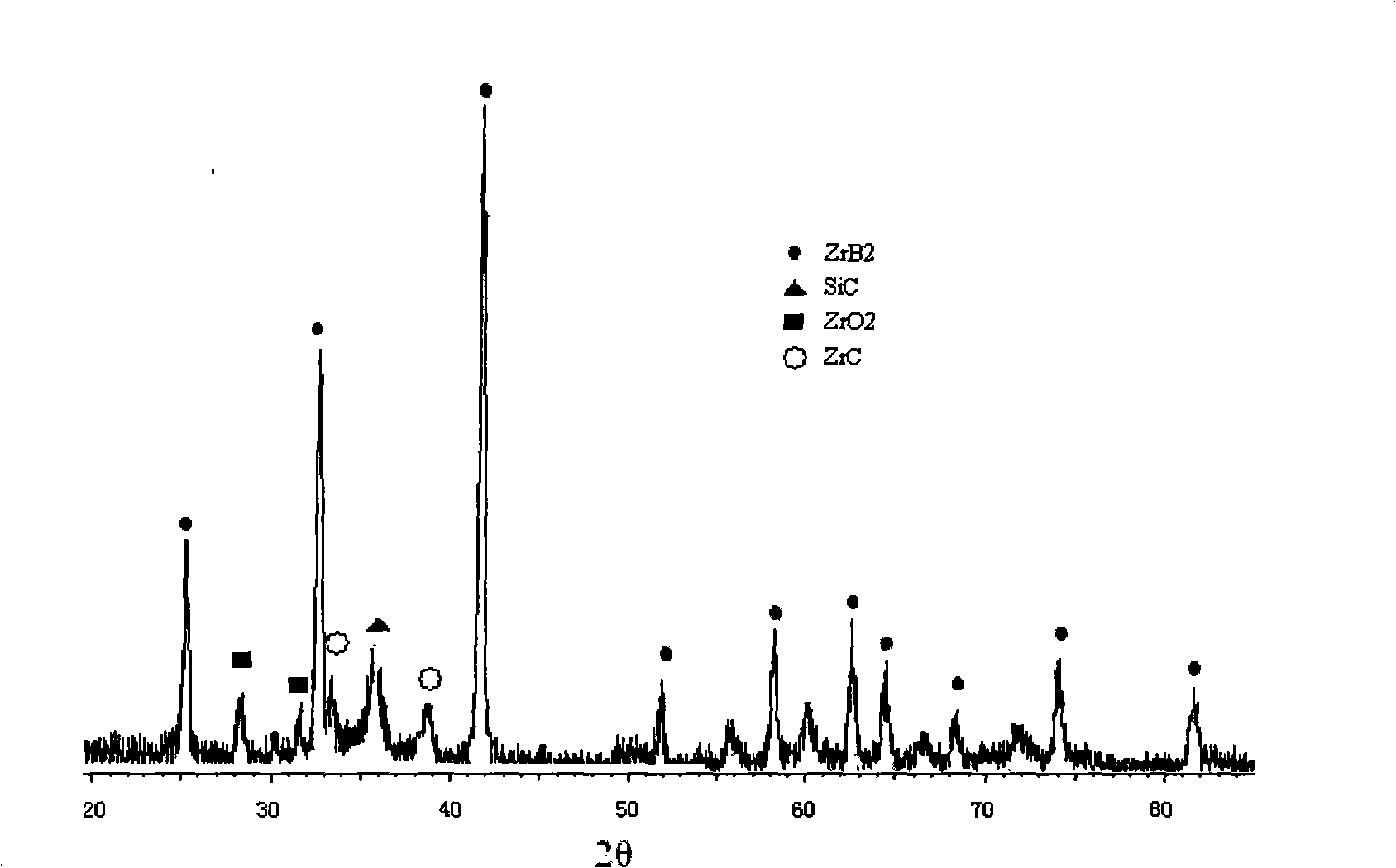

[0022] Step 2: Mix Zr powder, B powder, C powder and Si powder in a molar ratio of 1:2:0.15:0.2 to obtain mixed powder, add adhesive phenolic resin and diluent acetone, and mix the volume of powder, adhesive and diluent The ratio is 1:1:1, and the slurry for coating is formed after ball milling for 8 hours;

[0023] Step 3: evenly brush the above-mentioned coating slurry on the surface of the C / C composite material after drying, and the number of coating layers is 5;

[0024] Step 4: Place the pre-coated composite material in an oven to slowly heat up to 200°C, with a heating rate of 1°C / min, and cool down naturally after being kept fo...

Embodiment 2

[0028] Step 1: Set the density to 1.88g / cm 3 The surface of the dense 3D C / SiC composite was polished and smoothed, using acetone as the medium, ultrasonic cleaning for 60 minutes, and drying in an oven at 80 °C for 2 hours;

[0029] Step 2: Mix Zr powder and B powder in a molar ratio of 1:2 to obtain a mixed powder, add adhesive polycarbosilane / divinylbenzene mixed solution (volume ratio of 1:1) and diluent xylene, and the mixing The volume ratio of powder, adhesive and diluent is 1:1.5:0.5, and the slurry for coating is formed after ball milling for 24 hours;

[0030] Step 3: evenly brush the coating slurry on the surface of the C / SiC composite material, and the number of brushing layers is 4;

[0031] Step 4: Place the pre-coated composite material in an oven to slowly heat up to 180°C, with a heating rate of 1°C / min, and cool down naturally after being kept for 2 hours;

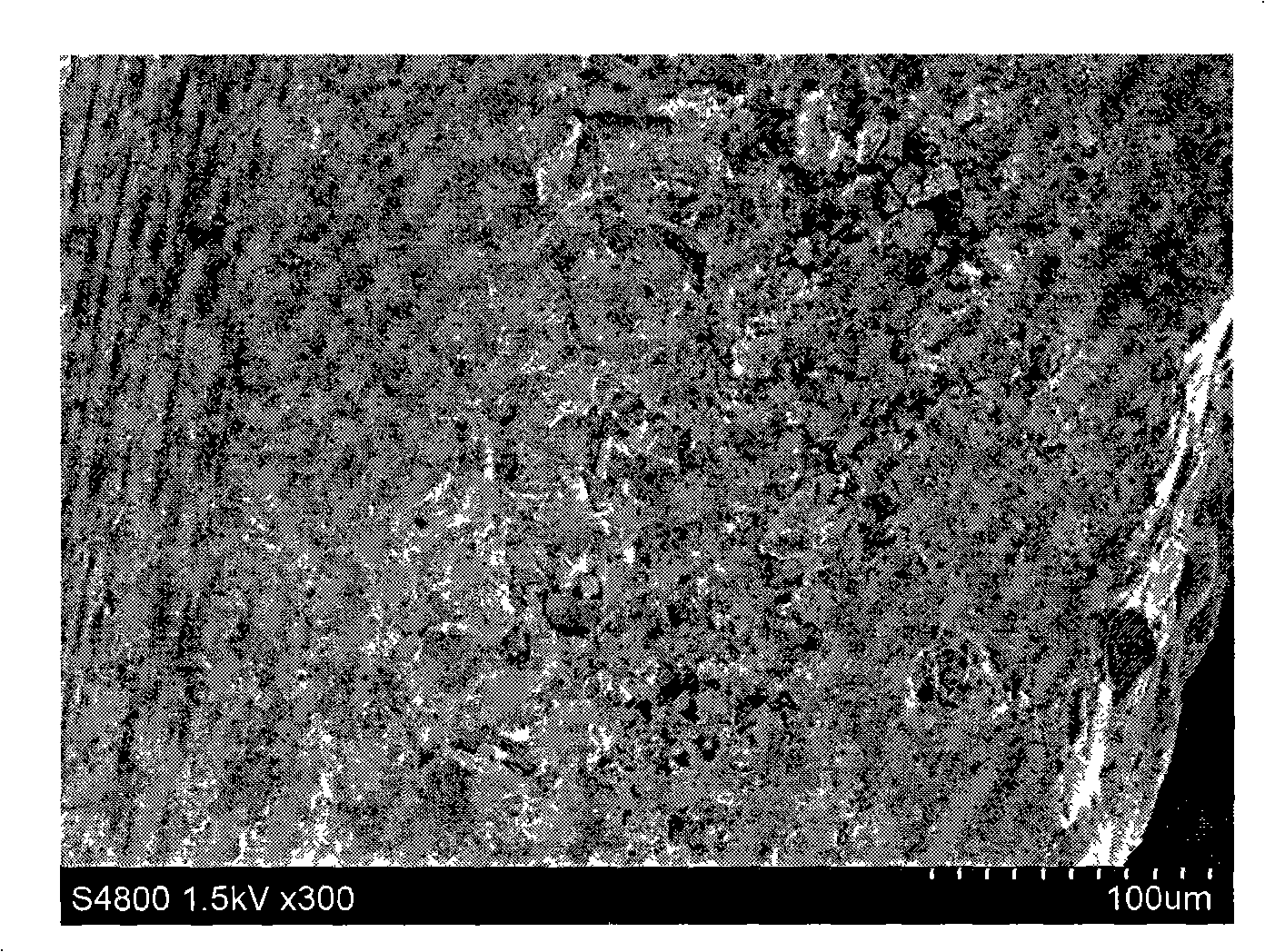

[0032] Step 5: Put the cured composite material of the precoat in a high-temperature sintering furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com