Boron modified phenolic resin and preparation method thereof

A phenolic resin and boron modification technology, applied in the field of boron modified phenolic resin and its preparation, can solve the problem that boron element affects heat resistance, ablation resistance and mechanical properties, etc., and achieves significant economic and social benefits, good Heat resistance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Feed according to the molar ratio of phenol and formaldehyde as 1:0.79, and weigh oxalic acid with a phenol mass of 7‰ as a catalyst, heat up to 95°C while stirring, and react for 3 hours;

[0016] 2) Adjust the vacuum degree of the reactor to 0.06MPa, and carry out dehydration under reduced pressure;

[0017] 3) Continue to heat up. When the temperature of the reaction solution rises to 120°C, add boric acid with 2% phenol mass, continue the reaction and raise the temperature to 140°C, and keep it warm for 1h;

[0018] 4) Adjust the vacuum degree of the reactor to 0.04MPa, and perform the second dehydration under reduced pressure;

[0019] 5) Continue to heat up, and discharge when the reaction temperature reaches 180°C.

Embodiment 2

[0021] 1) Feed according to the molar ratio of phenol and formaldehyde as 1:0.79, and weigh oxalic acid with a phenol mass of 7‰ as a catalyst, heat up to 100°C while stirring, and react for 5 hours;

[0022] 2) Adjust the vacuum degree of the reactor to 0.07MPa, and carry out dehydration under reduced pressure;

[0023] 3) Continue to heat up. When the temperature of the reaction solution rises to 130°C, add boric acid with 5% phenol mass, continue the reaction and raise the temperature to 140°C, and keep it warm for 1h;

[0024] 4) Adjust the vacuum degree of the reactor to 0.04MPa, and perform the second dehydration under reduced pressure;

[0025] 5) Continue to heat up, and discharge when the reaction temperature reaches 180°C.

Embodiment 3

[0027] 1) Feed according to the molar ratio of phenol and formaldehyde as 1:0.79, and weigh oxalic acid with a phenol mass of 7‰ as a catalyst, heat up to 98°C while stirring, and react for 4 hours;

[0028] 2) Adjust the vacuum degree of the reactor to 0.065MPa, and carry out dehydration under reduced pressure;

[0029] 3) Continue to heat up. When the temperature of the reaction solution rises to 125°C, add boric acid with 4% phenol mass, continue the reaction and raise the temperature to 140°C, and keep it warm for 1h;

[0030] 4) Adjust the vacuum degree of the reactor to 0.04MPa, and perform the second dehydration under reduced pressure;

[0031] 5) Continue to heat up, and discharge when the reaction temperature reaches 180°C.

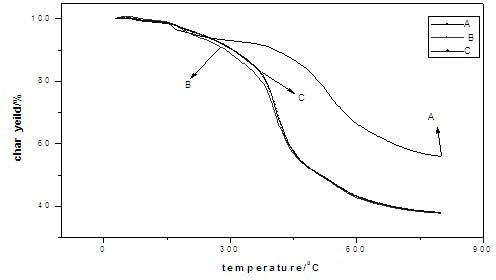

[0032] The high temperature resistance of the boron modified phenolic resin prepared by the invention is better than that of common phenolic resin. Comparison of thermal weight loss between boron modified phenolic resin and common phenolic resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com