Method for molding phenolic panel honeycomb sandwich structural member

A technology of honeycomb interlayer and molding method, which is applied in the field of molding of phenolic panel honeycomb sandwich structure, can solve the problems of good ablation resistance, bulging, debonding, etc., achieve good heat insulation and ablation resistance, improve structural rigidity, Good effect of ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

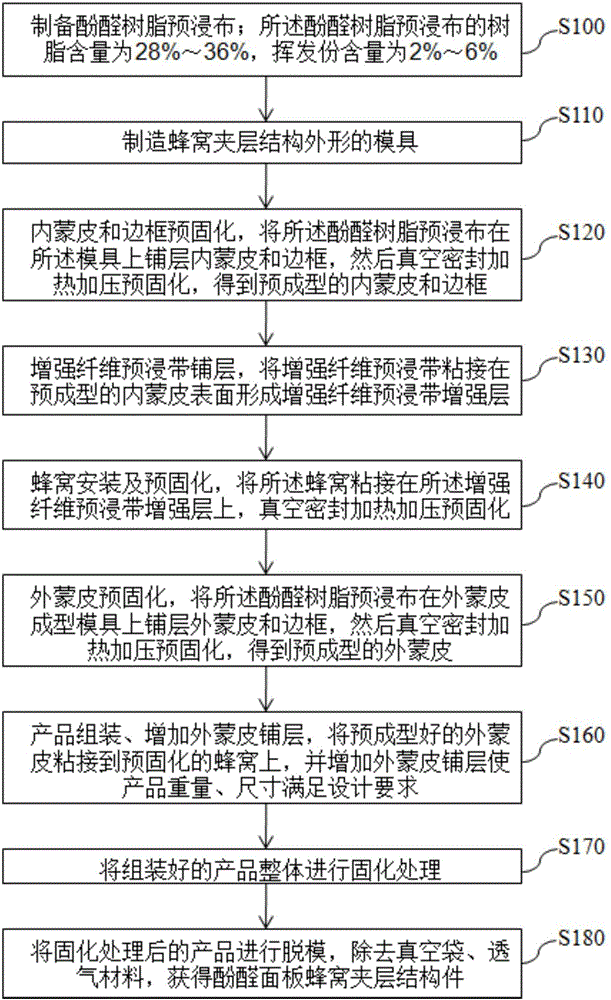

[0072] S1: preparing phenolic resin prepreg; the resin content of the phenolic resin prepreg is 28%, and the volatile matter content is 2%; the phenolic resin prepreg adopts quartz fiber cloth / phenolic resin prepreg;

[0073] S2: Manufacture the mold of honeycomb sandwich structure shape, and mold is single-sided mold, adopts steel material, and guarantees 0.5MPa airtight test and does not leak;

[0074] S3: Inner skin and frame pre-curing

[0075] S3.1, preheating the mold at 40°C and keeping it warm for 40min;

[0076] S3.2, cutting the phenolic resin prepreg into the required size and shape, laying the inner skin and frame on the mold, and laying the layers to the required thickness and weight;

[0077] S3.3, spread breathable material on the surface of inner skin and frame, and wrap vacuum bag;

[0078] S3.4, evacuate the mold and the laminated vacuum product in the autoclave, and pre-cure under pressure; wherein, the pre-curing temperature is 120°C, time is 2h, and the ...

Embodiment 2

[0101] S1: prepare a phenolic resin prepreg; the resin content of the phenolic resin prepreg is 32%, and the volatile matter content is 4%; the phenolic resin prepreg adopts alkali-free glass fiber cloth / phenolic resin prepreg;

[0102] S2: Manufacture the mold of honeycomb sandwich structure shape, and mold is single-sided mold, adopts steel material, and guarantees 0.5MPa airtight test and does not leak;

[0103] S3: Inner skin and frame pre-curing

[0104] S3.1, preheating the mold at 60°C and keeping it warm for 20 minutes;

[0105] S3.2, cutting the phenolic resin prepreg into the required size and shape, laying the inner skin and frame on the mold, and laying the layers to the required thickness and weight;

[0106] S3.3, spread breathable material on the surface of inner skin and frame, and wrap vacuum bag;

[0107] S3.4, evacuate the mold and the laminated vacuum product in the autoclave, and pre-cure under pressure; wherein, the pre-curing temperature is 130°C, time...

Embodiment 3

[0130] S1: preparing phenolic resin prepreg; the resin content of the phenolic resin prepreg is 36%, and the volatile matter content is 6%; the phenolic resin prepreg adopts high silica glass fiber cloth / phenolic resin prepreg;

[0131] S2: Manufacture the mold of the shape of the honeycomb sandwich structure, the mold is a single-sided mold, made of aluminum, and ensures that the 0.5MPa airtight test does not leak;

[0132] S3: Inner skin and frame pre-curing

[0133] S3.1, preheat the mold at 80°C and keep it warm for 10 minutes;

[0134] S3.2, cutting the phenolic resin prepreg into the required size and shape, laying the inner skin and frame on the mold, and laying the layers to the required thickness and weight;

[0135] S3.3, spread breathable material on the surface of inner skin and frame, and wrap vacuum bag;

[0136] S3.4, evacuate the mold and the laminated vacuum product in the autoclave, and pre-cure under pressure; wherein, the pre-curing temperature is 140°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com