Preparation method for modified graphene oxide, MGO-SiO2 nano-hybrid material and MGO-SiO2 modified phenolic resin hot melting adhesive film

A technology of nano-hybrid materials and phenolic resins, applied in chemical instruments and methods, film/sheet-like adhesives, adhesives, etc., can solve problems such as the performance of phenolic resin hot-melt adhesive films that have not been reported, and achieve good compatibility Sexuality and interfacial properties, excellent ablation resistance and wear resistance, and the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

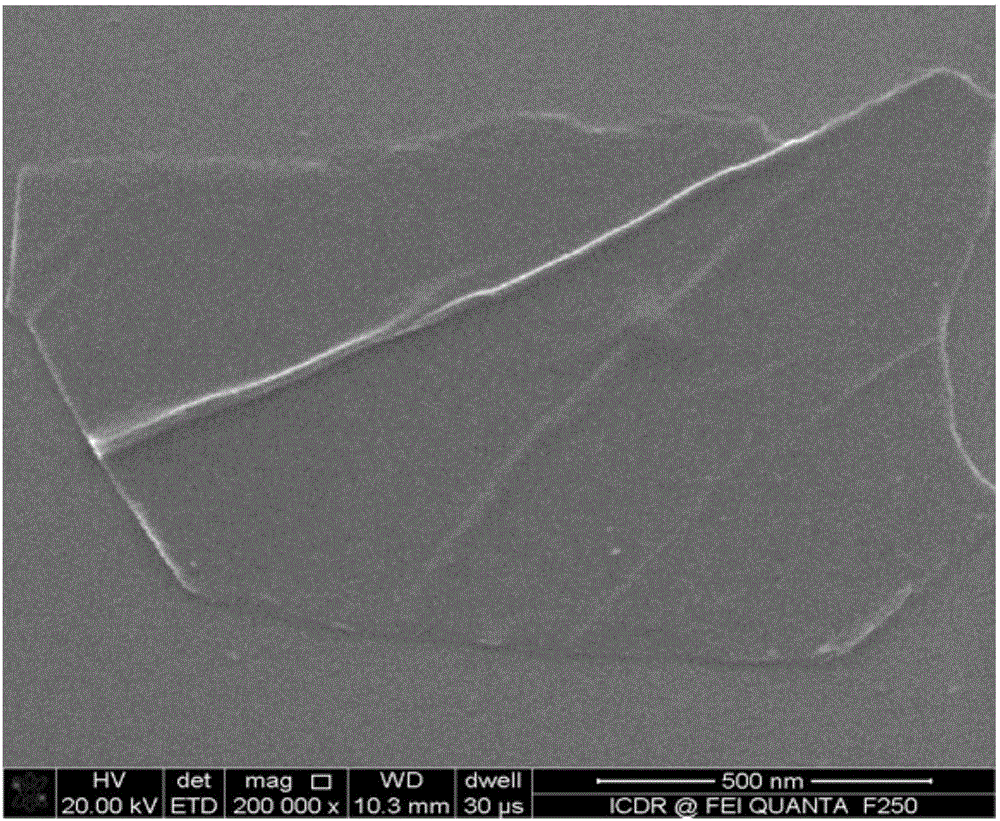

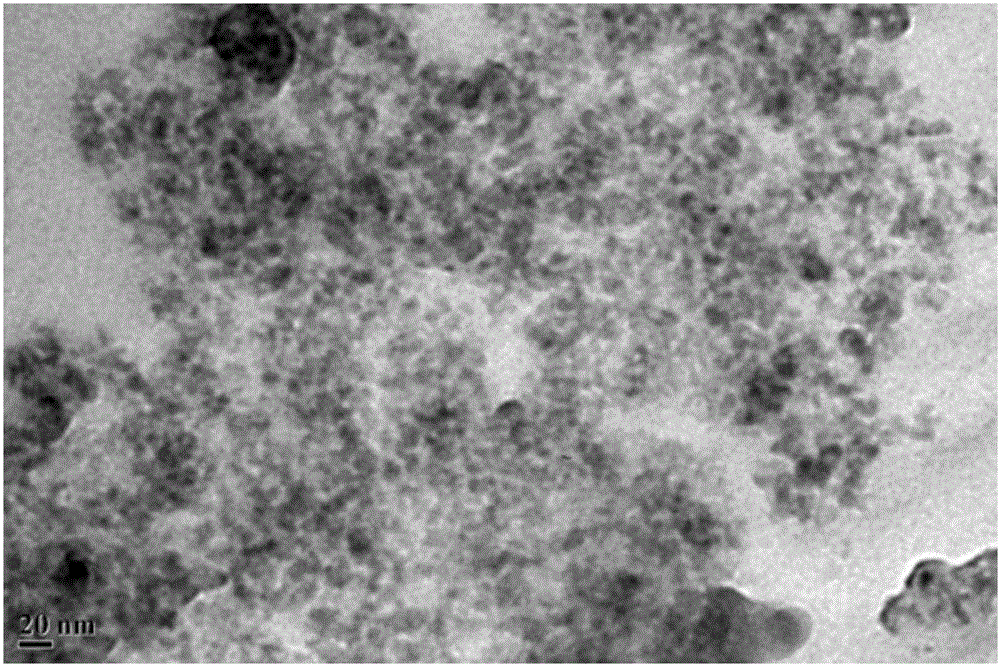

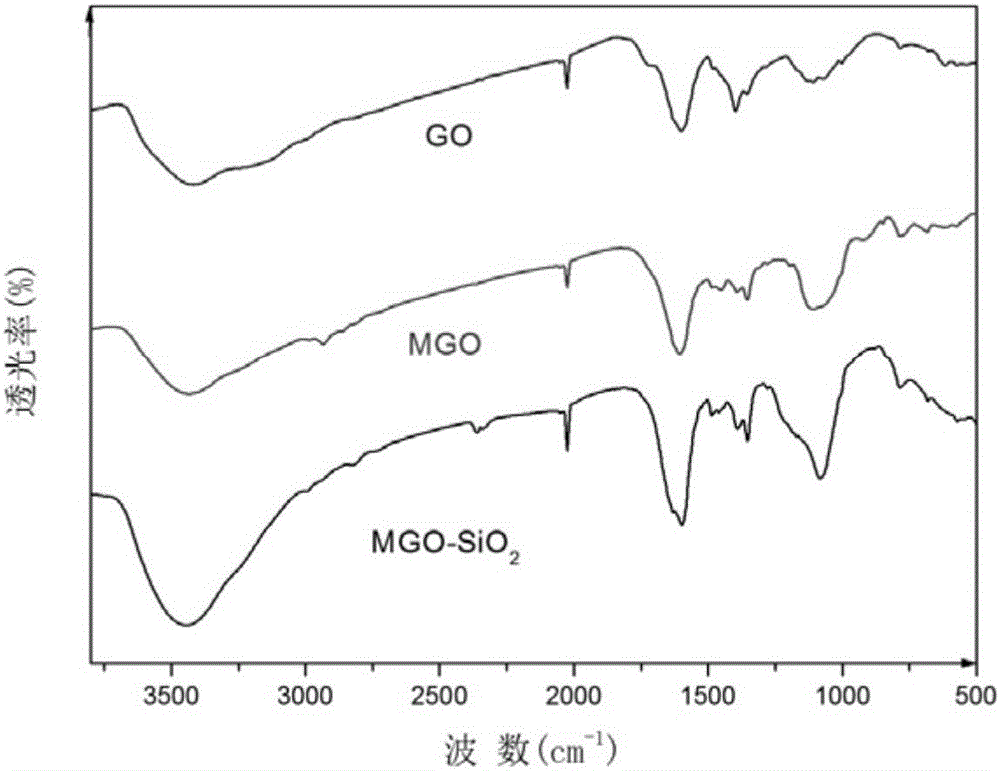

[0045] The preparation method of modified graphene oxide of the present invention comprises the following steps:

[0046] 1a) Weighing graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B, then adding graphite oxide to ethanol A, stirring for 1 hour and then ultrasonically dispersing for 2 hours to obtain a graphene oxide dispersion;

[0047] 2a) adding the catalyst to the graphene oxide dispersion obtained in step 1a) to obtain a mixed solution A;

[0048] 3a) Mix the silane coupling agent and ethanol B and stir for 30 minutes to obtain a mixed solution B, then add the mixed solution B to the mixed solution A, and stir and react at 75°C for 12 hours, and then carry out suction filtration and drying to obtain Modified graphene oxide;

[0049] Wherein, the ratio of graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B is 0.1g:50mL:0.05g:1.6g:20mL.

[0050] The catalyst is dicyclohexylcarbodiimide.

[0051] The silane coupling agent is γ...

Embodiment 2

[0067] The preparation method of modified graphene oxide of the present invention comprises the following steps:

[0068] 1a) Weighing graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B, then adding graphite oxide to ethanol A, stirring for 1 hour and then ultrasonically dispersing for 2 hours to obtain a graphene oxide dispersion;

[0069] 2a) adding the catalyst to the graphene oxide dispersion obtained in step 1a) to obtain a mixed solution A;

[0070] 3a) Mix the silane coupling agent and ethanol B and stir for 30 minutes to obtain a mixed solution B, then add the mixed solution B to the mixed solution A, and stir and react at 75°C for 12 hours, and then carry out suction filtration and drying to obtain Modified graphene oxide;

[0071] Wherein, the ratio of graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B is 0.1g:50mL:0.05g:1.6g:65mL.

[0072] The catalyst is triphenylphosphine.

[0073] The silane coupling agent is γ-(2,3-...

Embodiment 3

[0089] The preparation method of modified graphene oxide of the present invention comprises the following steps:

[0090] 1a) Weighing graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B, then adding graphite oxide to ethanol A, stirring for 3 hours and then ultrasonically dispersing for 3 hours to obtain a graphene oxide dispersion;

[0091]2a) adding the catalyst to the graphene oxide dispersion obtained in step 1a) to obtain a mixed solution A;

[0092] 3a) Mix the silane coupling agent with ethanol B and stir for 30 minutes to obtain a mixed solution B, then add the mixed solution B to the mixed solution A, and stir and react at 60°C for 12 hours, and then carry out suction filtration and drying to obtain Modified graphene oxide;

[0093] Wherein, the ratio of graphite oxide, ethanol A, catalyst, silane coupling agent and ethanol B is 0.1g:50mL:0.05g:1.5g:10mL.

[0094] The catalyst is a mixture of dicyclohexylcarbodiimide and triphenylphosphine in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com