Zr-based ceramic coating protection method for surface of refractory metal material

A refractory metal and ceramic coating technology, applied in metal material coating process, coating, electrolytic coating, etc., can solve the problem of low application temperature of silicide protective coating, achieve improved ablation resistance, low temperature , good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

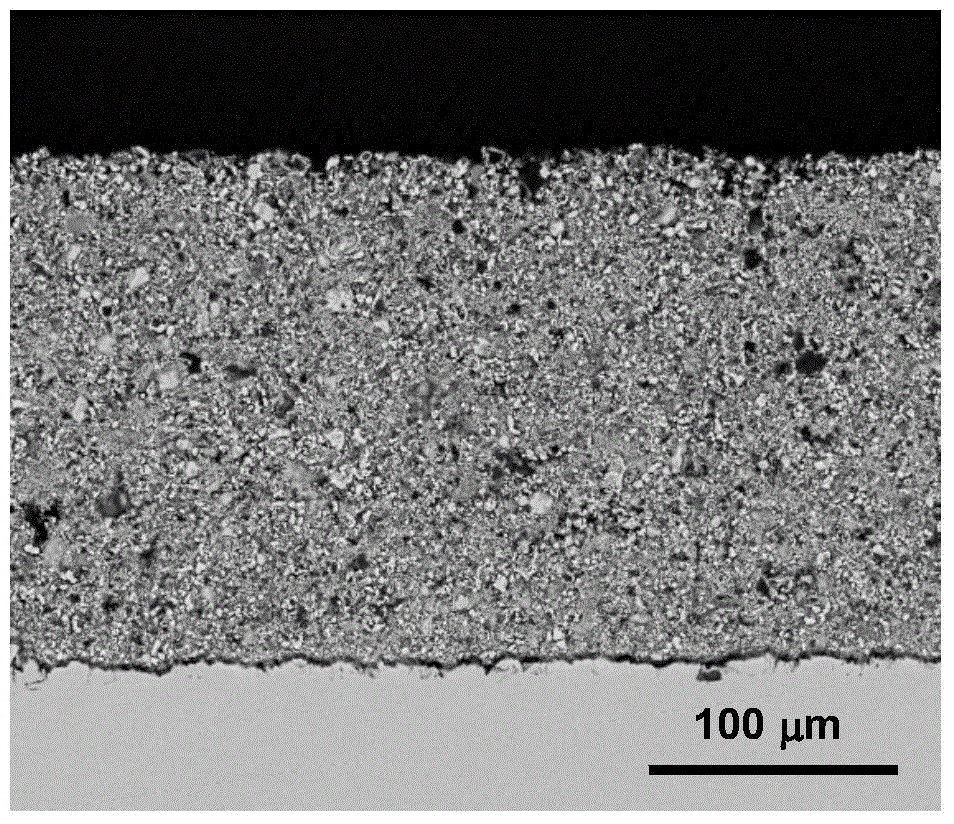

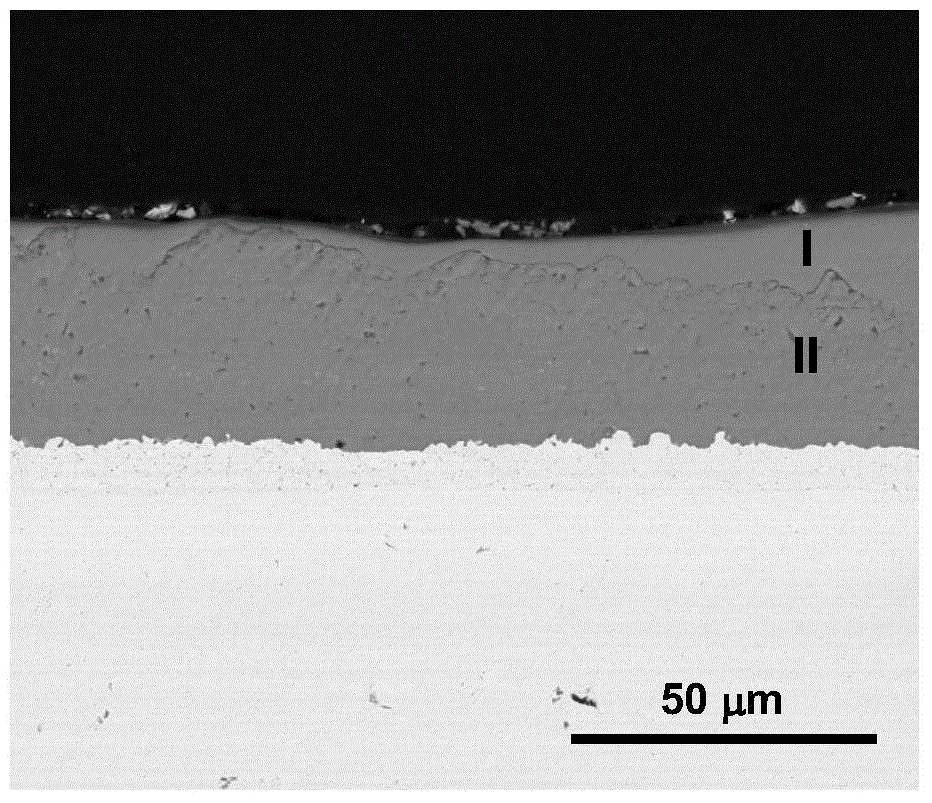

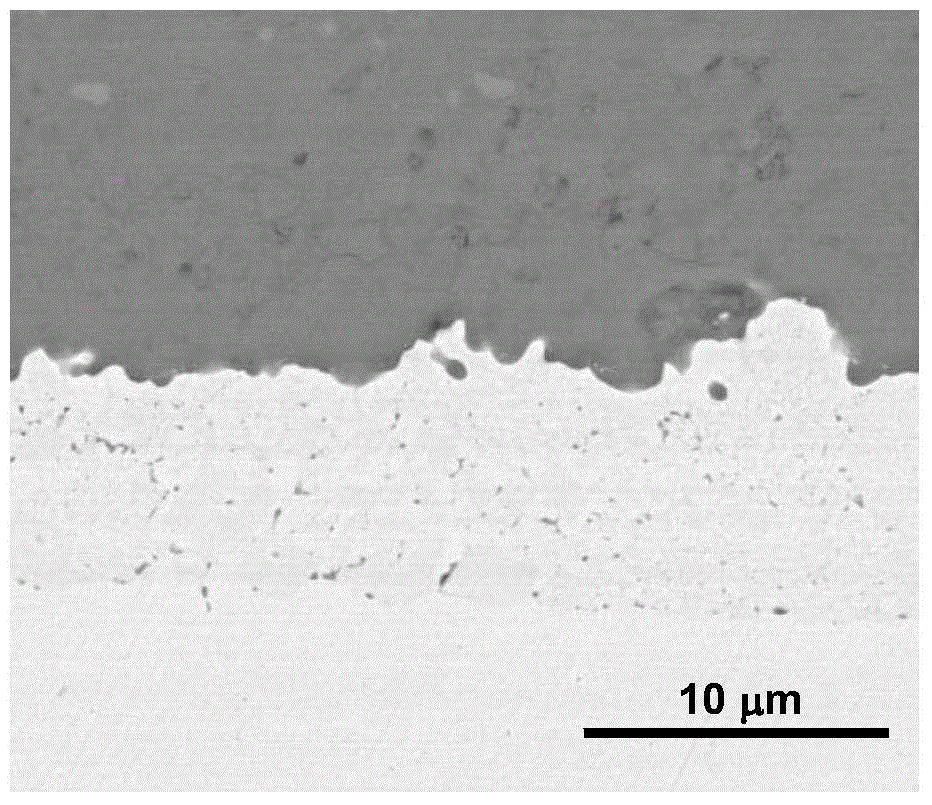

[0026] In a specific embodiment, the present invention provides a Zr-based ceramic coating protection method on the surface of a refractory metal material: first, degreasing and sanding the refractory metal; then, using electrophoresis technology to deposit Zr-based ceramic powder on the refractory The surface of the molten metal is formed to form a Zr-based ceramic powder pre-layer; after that, the laser cladding technology is used to clad the Zr-based ceramic powder pre-layer on the refractory metal surface to obtain an ablation-resistant Zr-based ceramic coating.

[0027] Hereinafter, the present invention will be described in further detail through examples and accompanying drawings.

[0028] Example: with ZrB 2 The application of ceramic coating in improving the ablation resistance of Ta-2.5wt.% W alloy is an example.

[0029] 1. Preparation of coating:

[0030] 1) Substrate pretreatment

[0031] Process the Ta-2.5wt.%W substrate into a sample with a size of 15mm long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com