Vanadium oxide/carbon/clay composite positive electrode material as well as preparation method and application thereof in aqueous battery

A composite positive electrode material and vanadium oxide technology, which is applied in the field of electrochemistry, can solve the problems of insufficient electronic conductivity and poor ion diffusivity, and achieve the effects of promoting diffusion and transportation, low preparation cost, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

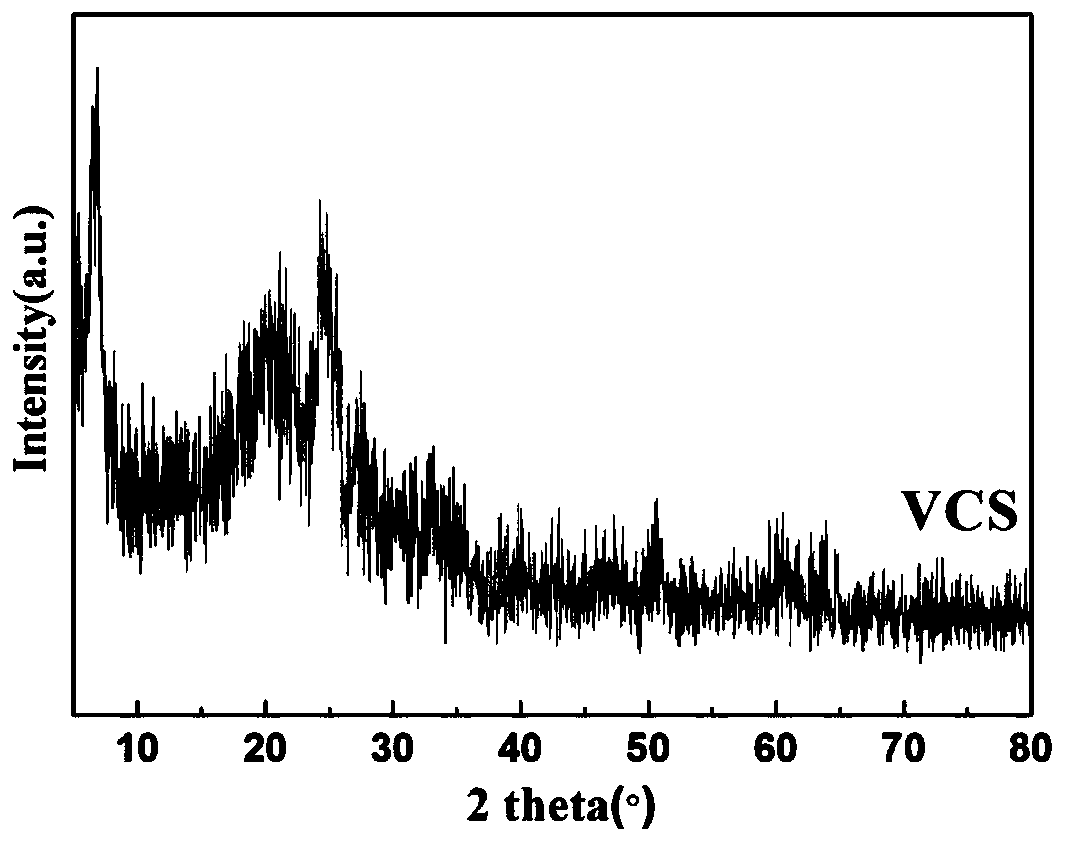

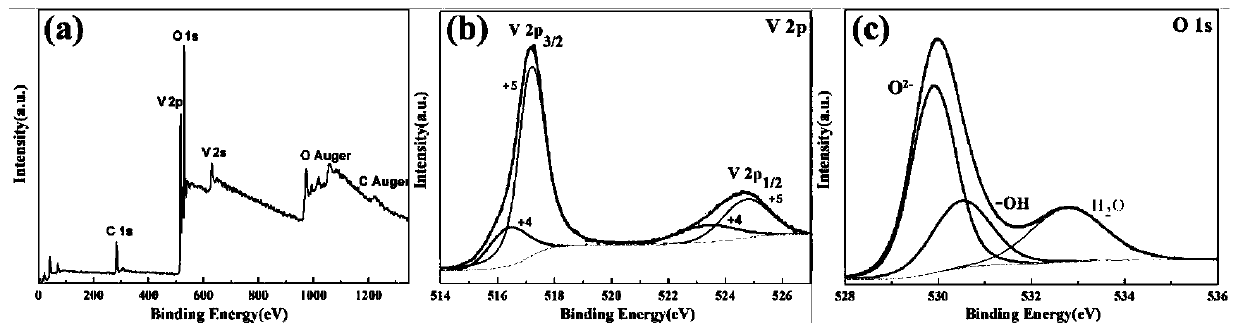

[0055] (1) Pretreatment of sepiolite: Treat raw sepiolite with 4mol / L hydrochloric acid at 85°C for 8 hours (the ratio of raw sepiolite to hydrochloric acid is 1g:50mL), and dry at 80°C for 24h , ground to a particle size of 500 mesh for later use, the structure of sepiolite has changed before and after treatment, and its main component is amorphous SiO 2 ..

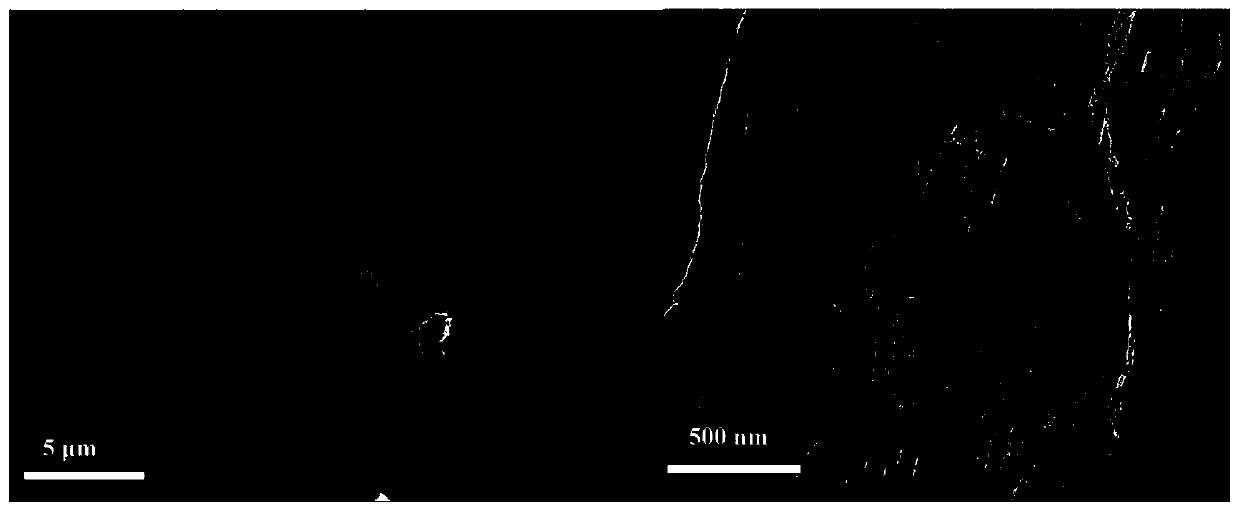

[0056] (2) Preparation of hydrophilic vanadium oxide / carbon nanotube / sepiolite aqueous battery composite positive electrode material: first, V 2 o 5 Powder: H 2 o 2 Solution=1g:50mL ratio, add H 2 o 2 Solution, under the temperature condition of 5 ℃, ultrasonic, stirring and mixing evenly, ultrasonic 20min, ultrasonic power is 100W, stirring rate is 500r / min, stirring time is 20min; then slowly add carbon nanotube powder, sea foam stone powder (V 2 o 5 The mass ratio of powder, carbon nanotube powder, and sepiolite powder is 50:20:30) ultrasonication, stirring, mixing and stirring evenly, the stirring rate is 600...

Embodiment 2

[0061] (1) Pretreatment of sepiolite: Treat raw sepiolite with 4mol / L hydrochloric acid at 85°C for 8 hours (the ratio of raw sepiolite to hydrochloric acid is 1g:50mL), and dry at 80°C for 24h , Grind to a particle size of 500 mesh for later use.

[0062] (2) Preparation of hydrophilic vanadium oxide / carbon nanotube / sepiolite aqueous battery composite positive electrode material: first, in terms of mass percentage, take V 2 o 5 powder, with V 2 o 5 Powder: H 2 o 2 Solution=1g:50mL ratio, add H 2 o 2 Solution, under the temperature condition of 5 ℃, ultrasonic, stirring and mixing evenly, ultrasonic 20min, ultrasonic power is 100W, stirring rate is 500r / min, stirring time is 20min; then slowly add carbon nanotube powder, sea foam stone powder (V 2 o 5 The mass ratio of powder, carbon nanotube powder and sepiolite powder is 65:25:10) ultrasonication, stirring, mixing and stirring evenly, the stirring speed is 600r / min, and the stirring time is 40min; then pour the mixe...

Embodiment 3

[0067] (1) Pretreatment of sepiolite: Treat raw sepiolite with 4mol / L hydrochloric acid at 85°C for 8 hours (the ratio of raw sepiolite to hydrochloric acid is 1g:50mL), and dry at 80°C for 24h , Grind to a particle size of 500 mesh for later use.

[0068] (2) Preparation of hydrophilic vanadium oxide / carbon nanotube / sepiolite aqueous battery composite positive electrode material: first, in terms of mass percentage, take V 2 o 5 powder, with V 2 o 5 Powder: H 2 o 2 Solution=1g:50mL ratio, add H 2 o 2 Solution, under the temperature condition of 5 ℃, ultrasonic, stirring and mixing evenly, ultrasonic 20min, ultrasonic power is 100W, stirring rate is 500r / min, stirring time is 20min; then slowly add carbon nanotube powder, sea foam stone powder (V 2 o 5 The mass ratio of powder, carbon nanotube powder, and sepiolite powder is 60:22:18) ultrasonication, stirring, mixing and stirring evenly, the stirring rate is 600r / min, and the stirring time is 40min; then pour the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com