A kind of preparation method of oxygen evolution catalyst based on metal organic framework material

A metal-organic framework and catalyst technology, which is applied in the field of oxygen evolution catalysts, can solve the problems that the catalytic activity needs to be further improved and needs to be further improved, and achieve the effects of good oxygen evolution stability, excellent oxygen evolution reaction activity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

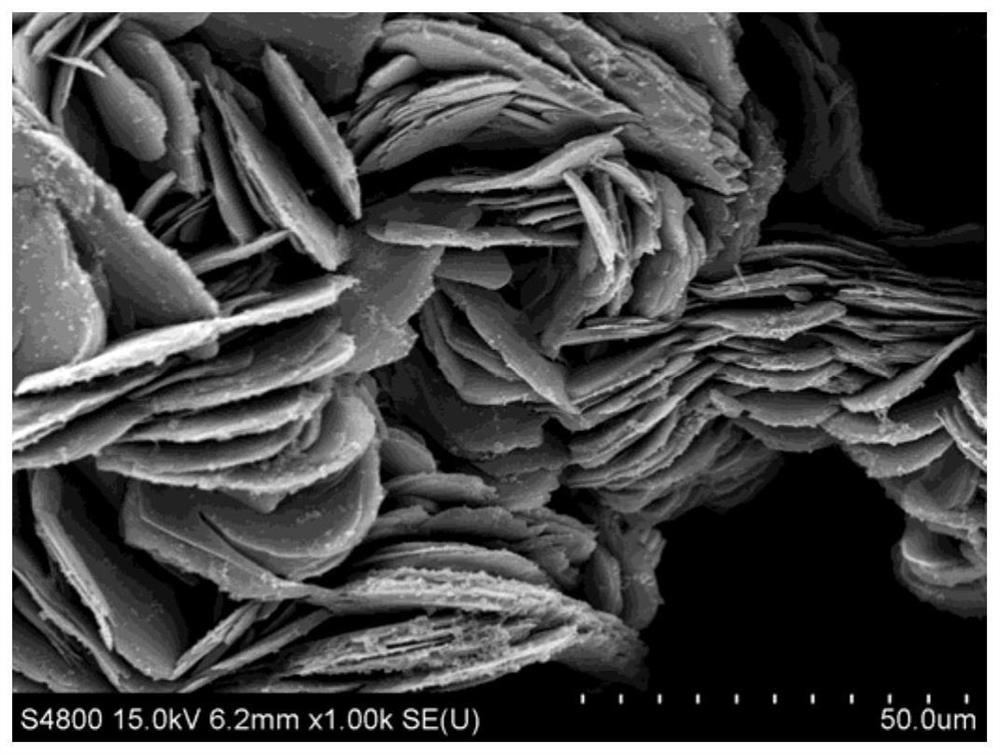

[0028] Step 1, prepare a nitrogen-nitrogen dimethylformamide solution containing ferric chloride and terephthalic acid, wherein the concentrations of ferric chloride and terephthalic acid are respectively 0.6mmol / L and 0.6mmol / L, and the mixed solution is transferred. into a 100 ml reactor;

[0029] Step 2, immersing the washed nickel foam into the above mixed solution, and performing hydrothermal reaction at 150° C. for 15 hours;

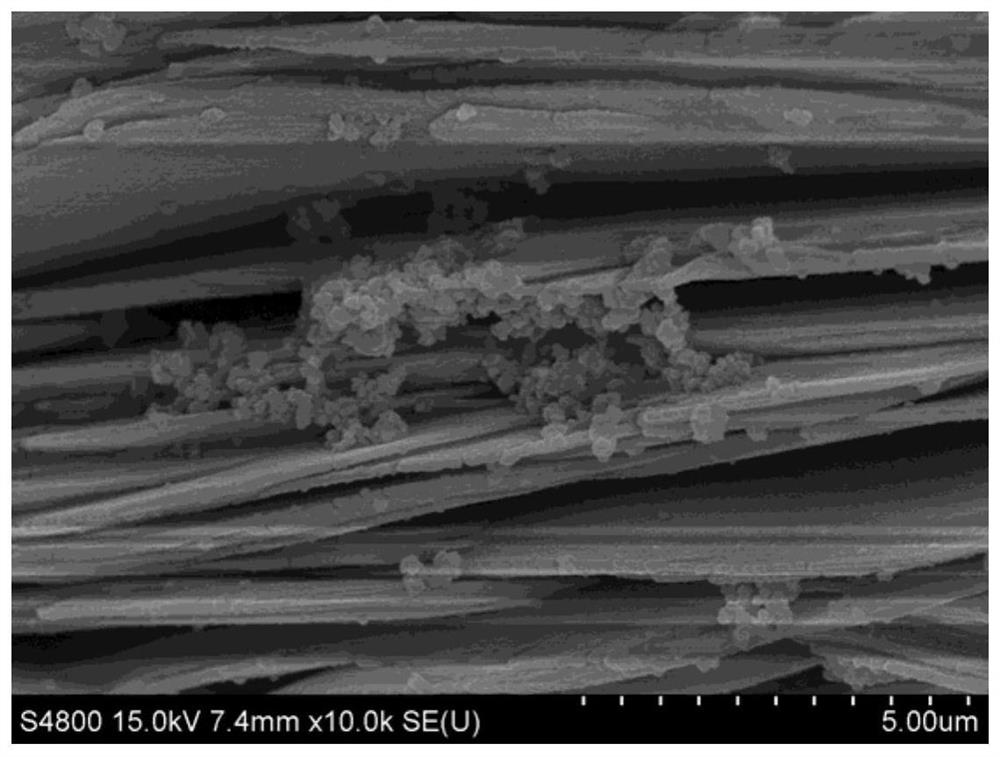

[0030] In step 3, the nickel foam on which the metal organic framework material is grown is rinsed with water and dried in vacuum. The three-electrode system was then assembled. Using the above-mentioned foamed nickel as the working electrode, Ag / AgCl as the reference electrode, and Pt as the counter electrode, galvanostatic deposition experiments were carried out. The electrolyte is 50 mmol / L nickel chloride and 1 mol / L thiourea mixed solution. Deposition current density of 1 mA cm -2 , the deposition time was 25 minutes.

[0031] After the r...

Embodiment 2

[0035] This example is basically the same as Example 1, except that the electrodeposition time is 15 minutes, and other conditions remain the same.

Embodiment 3

[0037] This example is basically the same as Example 1, except that the electrodeposition time is 5 minutes, and other conditions remain the same.

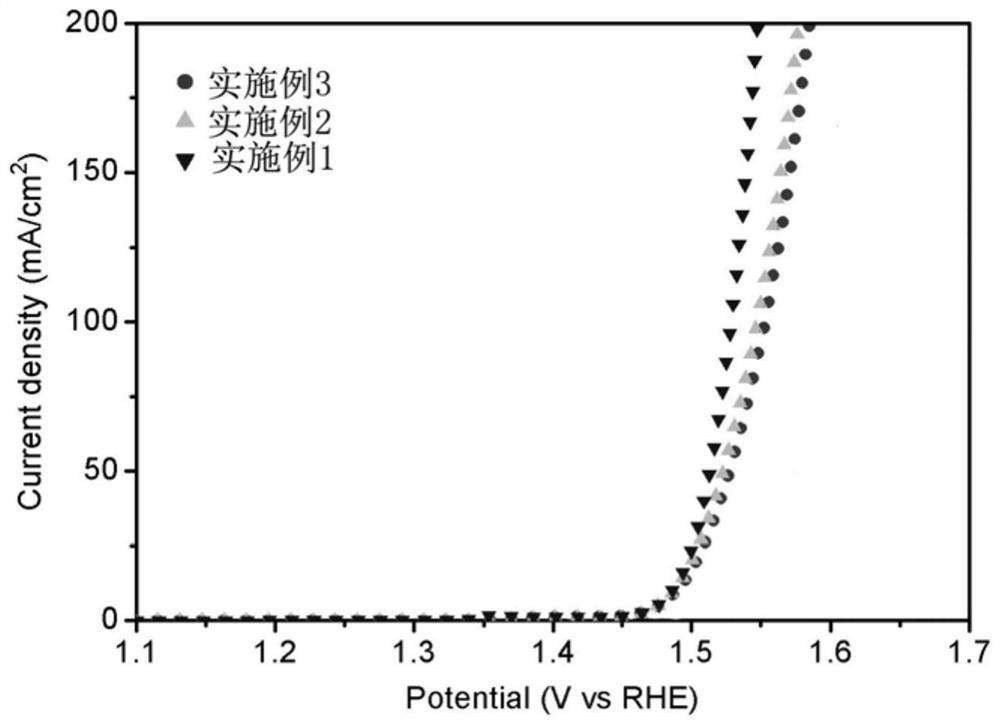

[0038] The oxygen evolution reaction was carried out in 1 mol / L KOH electrolyte. Depend on image 3 It can be seen that the electrodeposition time is 25 min and the sample reaches 100 mA cm -2 , the required overpotential is only 298mV. For Example 2 and Example 3, to achieve the same current density, the required overpotentials were 316 mV and 326 mV, respectively. It shows that the deposition time can affect the oxygen evolution catalytic performance of the final product.

[0039] Depend on Figure 4 It can be seen that at 100mA cm -2 The galvanostatic experiment was carried out at the current density of 1, and the reaction was carried out for 40 hours, and the overpotential hardly changed, indicating that Example 1 has excellent catalytic stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com