Ecological geometry self-expanding structure simulation moving bed

A technology of simulating moving bed and self-expansion, which is applied in the field of simulating moving bed of ecological geometric self-expanding structure, can solve the problems of uneven distribution of fluid, large pressure drop of the flow entering and leaving the grid, and increasing the load of the adsorption tower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

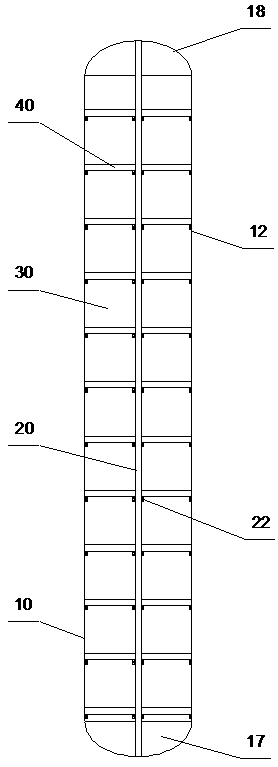

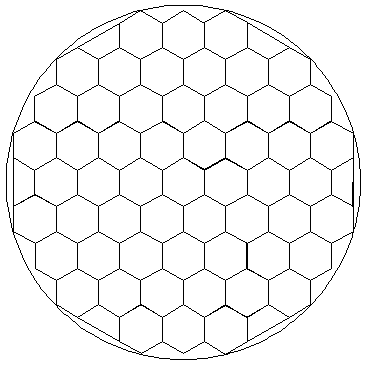

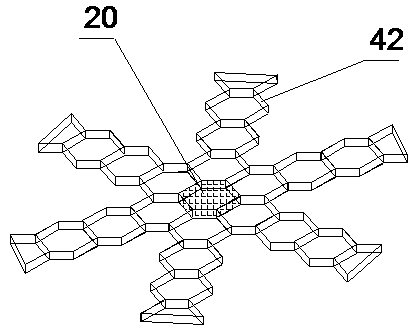

[0049] The present invention is a simulated moving bed with an ecological geometric self-expanding structure suitable for the efficient separation of liquid and solid systems, which includes a vertical shell in which several grid layers are arranged alternately up and down in sequence, and the shell is arranged along the axis and runs through the top of the tower The regular hexagonal cross-section long column at the bottom is used as the central support (can be called the central column), and the grid layer is set from each side of the central column to naturally radiate to the inner wall of the adsorption tower in units of regular hexagonal grid units. The 6 main frames (which can be called radial grid strips) form an ecological geometrically expanded hexagonal star-shaped radiation structure, which is used as the supporting skeleton of the single-layer grid layer. Each main frame is integrally formed outside the tower and integrated hoisted into the tower. The space between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com