Manufacturing method of high-performance thermal-insulating composite carbon fiber plate

A composite carbon fiber and manufacturing method technology, applied in the direction of textiles and papermaking, etc., can solve the problems of low carbon fiber hard felt, poor oxidation resistance, high binder content, etc., to achieve not easy to crack, good self-supporting performance, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

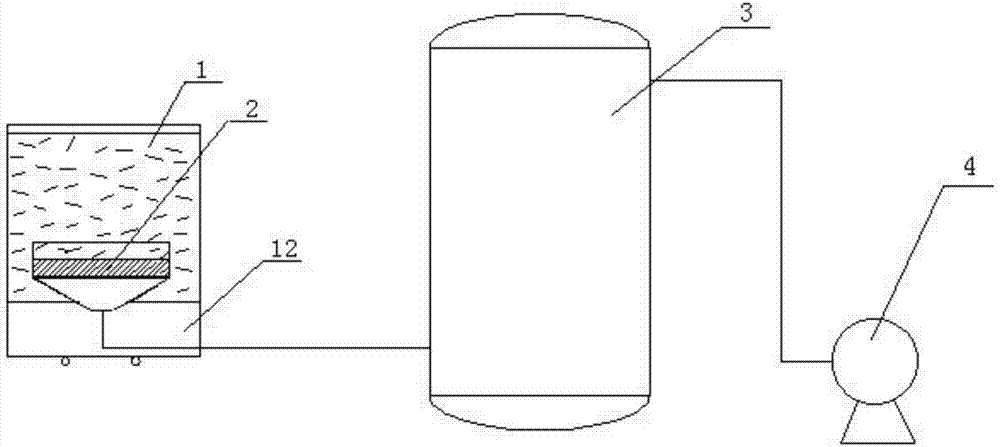

[0070] In the present embodiment, the manufacturing method of the high-performance composite carbon fiber insulation board is as follows:

[0071] 1) Prepare chopped carbon fibers; chop the pitch-based carbon fibers to obtain chopped carbon fibers with an average length of 40 mm;

[0072] 2) preparing ground carbon fibers; grinding the pitch-based carbon fibers to obtain ground carbon fibers with an average length of 100 μm;

[0073] 3) using a cyclone separator to fully mix the chopped carbon fiber and the ground carbon fiber according to the weight ratio of 60:40 to obtain the mixed carbon fiber;

[0074] 4) Mix the mixed carbon fiber with the organic binder phenolic resin and solvent ethanol in a weight ratio of 100:30:70 to obtain a carbon fiber mixture; put the carbon fiber mixture into a mesh bag, pass through a mesh with a mesh size of 30 μm After the initial filtration of the bag, use hot air at 50°C to blow directly into the mesh bag for 30 minutes to completely vola...

Embodiment 2

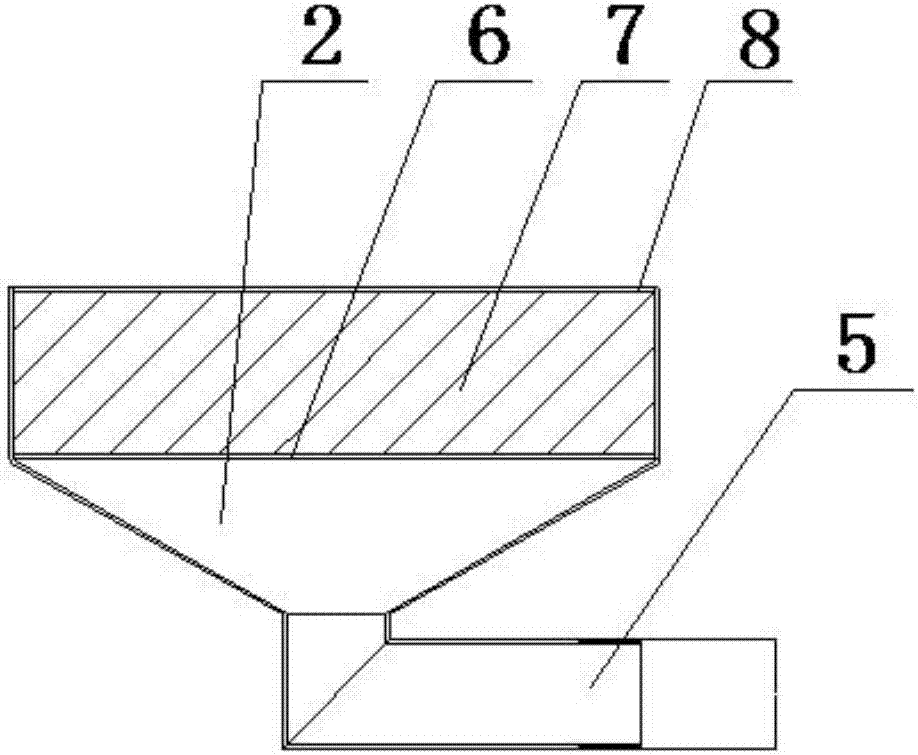

[0082] In order to increase the anti-airflow erosion and anti-oxidation properties of the composite carbon fiber insulation board 9, and further improve its service life; the composite carbon fiber insulation board 9 prepared in [Example 1] is subjected to surface treatment, and the specific steps of the surface treatment are as follows:

[0083] 1) The composite carbon fiber insulation board 9 is machined for surface polishing treatment to make the surface smooth;

[0084]2) Brush the adhesive agent on the upper and lower surfaces of the composite carbon fiber insulation board 9 after the polishing treatment, respectively, for 3 to 6 times to form the adhesive layer 10, and the adhesive agent can be conventionally used;

[0085] 3) Put the composite carbon fiber insulation board 9 coated with the adhesive layer 10 into a heating furnace, raise the temperature to 240° C. at a heating rate of 5° C. / min, keep the temperature at this temperature for 1 hour, and cure the adhesive l...

Embodiment 3

[0088] In the present embodiment, the manufacturing method of the high-performance composite carbon fiber insulation board is as follows:

[0089] 1) Prepare chopped carbon fibers; chop the pitch-based carbon fibers to obtain chopped carbon fibers with an average length of 80 mm;

[0090] 2) preparing ground carbon fibers; grinding the pitch-based carbon fibers to obtain ground carbon fibers with an average length of 180 μm;

[0091] 3) Using a cyclone separator to fully mix the chopped carbon fiber and the ground carbon fiber according to the weight ratio of 50:50 to obtain the mixed carbon fiber;

[0092] 4) Mix the mixed carbon fiber with the organic binder phenolic resin and solvent ethanol in a weight ratio of 100:55:75 to obtain a carbon fiber mixture; put the carbon fiber mixture into a mesh bag, pass through a mesh with a mesh size of 30 μm After the bag is pre-filtered, hot air at 60°C is blown directly into the mesh bag for 30 minutes to completely evaporate the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com