Preparation method of 2,5-furandicarboxylic acid

A furandicarboxylic acid and catalyst technology, which is applied in the chemical industry, can solve the problems of wasteful storage of raw materials, easy spontaneous oxidation and deterioration, and difficulty in ensuring purity, and achieves the effects of no energy waste, excellent catalytic performance, and good hydrogen production capacity by electrolysis of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

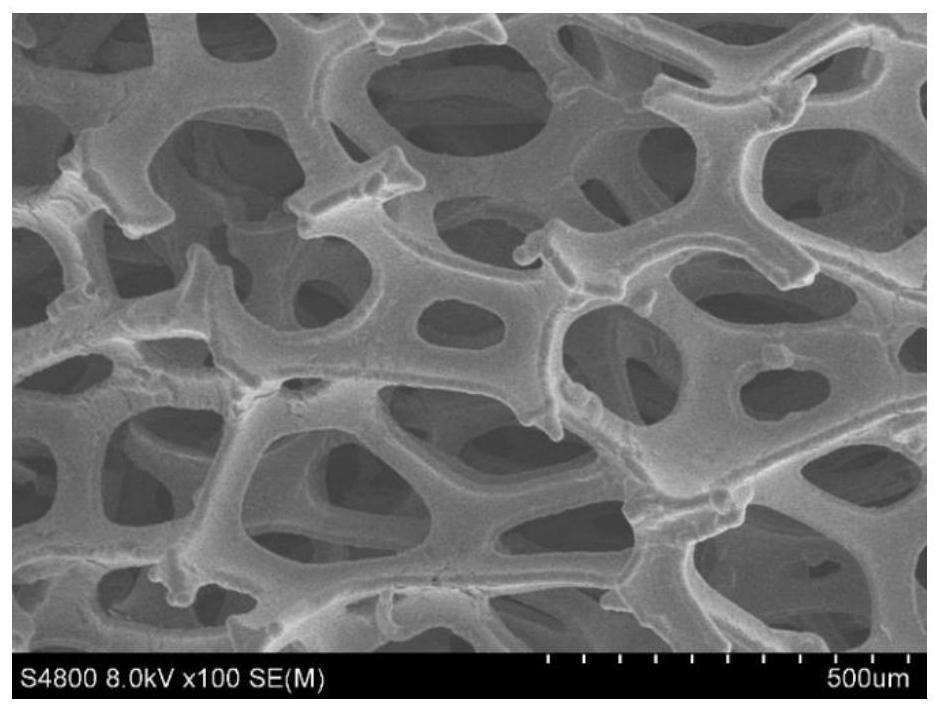

[0112] (1) Put 1500mg of sublimated sulfur powder in the corundum boat of the tube furnace, seal it and dry it in 100mL / min nitrogen atmosphere at 30°C for 2h to remove the contained moisture.

[0113] (2) Submerge 280mg of cobalt foam in absolute ethanol and ultrasonically clean it for 10min, and then dry it at 60°C for 4h.

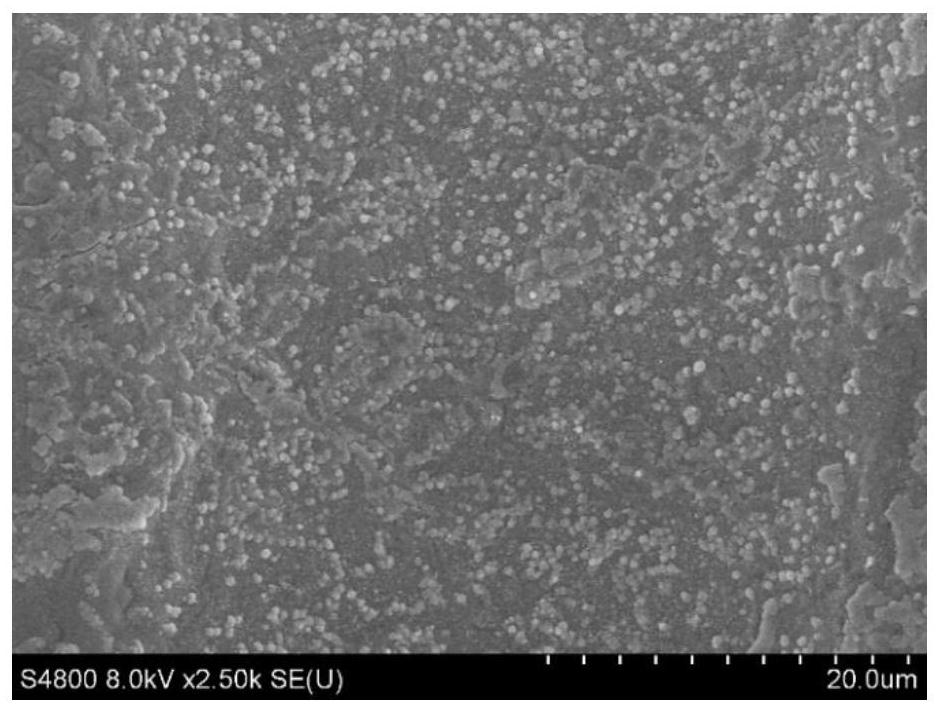

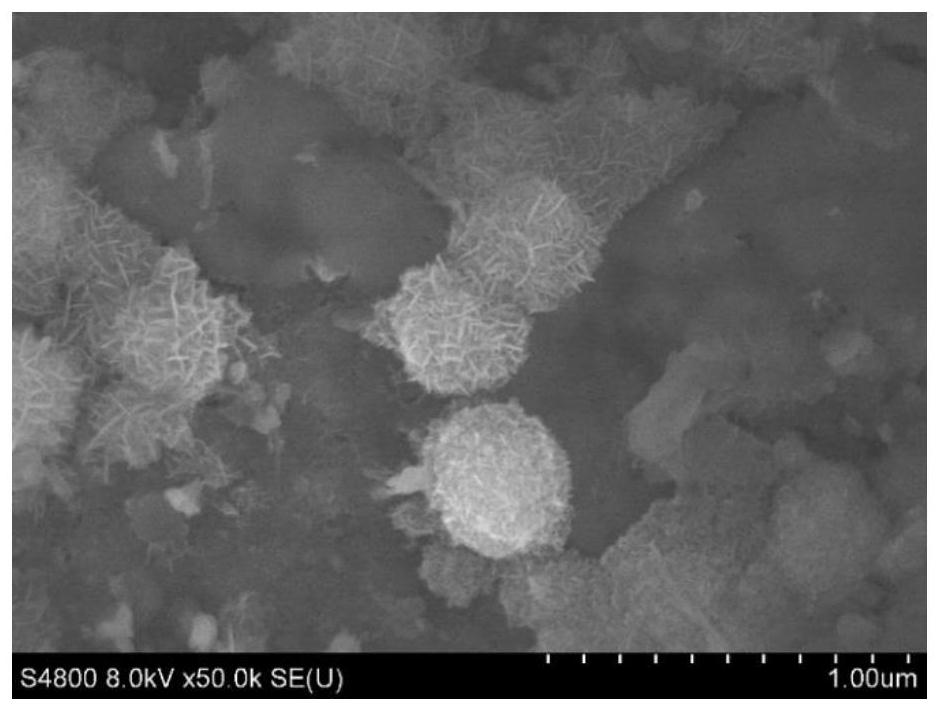

[0114] (3) the dry sublimed sulfur powder that step (1) obtains and the cobalt foam that obtains in the step (2) are placed in the corundum boat of tube furnace jointly, pass into high-purity nitrogen as full-range protective gas after sealing, wherein nitrogen The flow rate was 50mL / min; the temperature was raised to 350°C at a rate of 5°C / min, and after holding for 0.5h, it was naturally cooled to room temperature to obtain the precursor. Among them, the mass ratio of sublimated sulfur powder to cobalt foam is 5.4:1.

[0115] (4) The precursor obtained in step (3) is used as the anode, the graphite rod is used as the cathode, and the mercury / mercuric ...

Embodiment 2

[0117] (1) Put 1500mg of sublimated sulfur powder in the corundum boat of the tube furnace, seal it and dry it in 100mL / min nitrogen atmosphere at 30°C for 2h to remove the contained moisture.

[0118] (2) Submerge 500 mg of cobalt foam in absolute ethanol and ultrasonically clean it for 10 min, and then dry it at 60° C. for 4 h.

[0119] (3) the dry sublimed sulfur powder that step (1) obtains and the cobalt foam that obtains in the step (2) are placed in the corundum boat of tube furnace jointly, pass into high-purity nitrogen as full-range protective gas after sealing, wherein nitrogen The flow rate was 50mL / min; the temperature was raised to 350°C at a rate of 5°C / min, and after holding for 0.5h, it was naturally cooled to room temperature to obtain the precursor. Among them, the mass ratio of sublimated sulfur powder to cobalt foam is 3:1.

[0120] (4) The precursor obtained in step (3) is used as the anode, the graphite rod is used as the cathode, and the mercury / mercur...

Embodiment 3

[0123] (1) Put 500mg of sublimated sulfur powder in a corundum boat of a tube furnace, seal it and dry it in a nitrogen atmosphere of 100mL / min at 30°C for 2h to remove the contained moisture.

[0124] (2) Submerge 280mg of cobalt foam in absolute ethanol and ultrasonically clean it for 10min, and then dry it at 60°C for 4h.

[0125] (3) the dry sublimed sulfur powder that step (1) obtains and the cobalt foam that obtains in the step (2) are placed in the corundum boat of tube furnace jointly, pass into high-purity nitrogen as full-range protective gas after sealing, wherein nitrogen The flow rate was 50mL / min; the temperature was raised to 350°C at a rate of 5°C / min, and after holding for 0.5h, it was naturally cooled to room temperature to obtain the precursor. Among them, the mass ratio of sublimated sulfur powder to cobalt foam is 1.8:1.

[0126] (4) The precursor obtained in step (3) is used as the anode, the graphite rod is used as the cathode, and the mercury / mercuric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com